Method for processing gear inner hole key slot and special device

A special device and inner hole technology, applied in broaching devices, metal processing equipment, manufacturing tools, etc., can solve the problems of low precision, high noise, wire cutting, low EDM efficiency, etc., and achieve low production and equipment costs , Occupying a small area of the factory building, the effect of convenient equipment movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

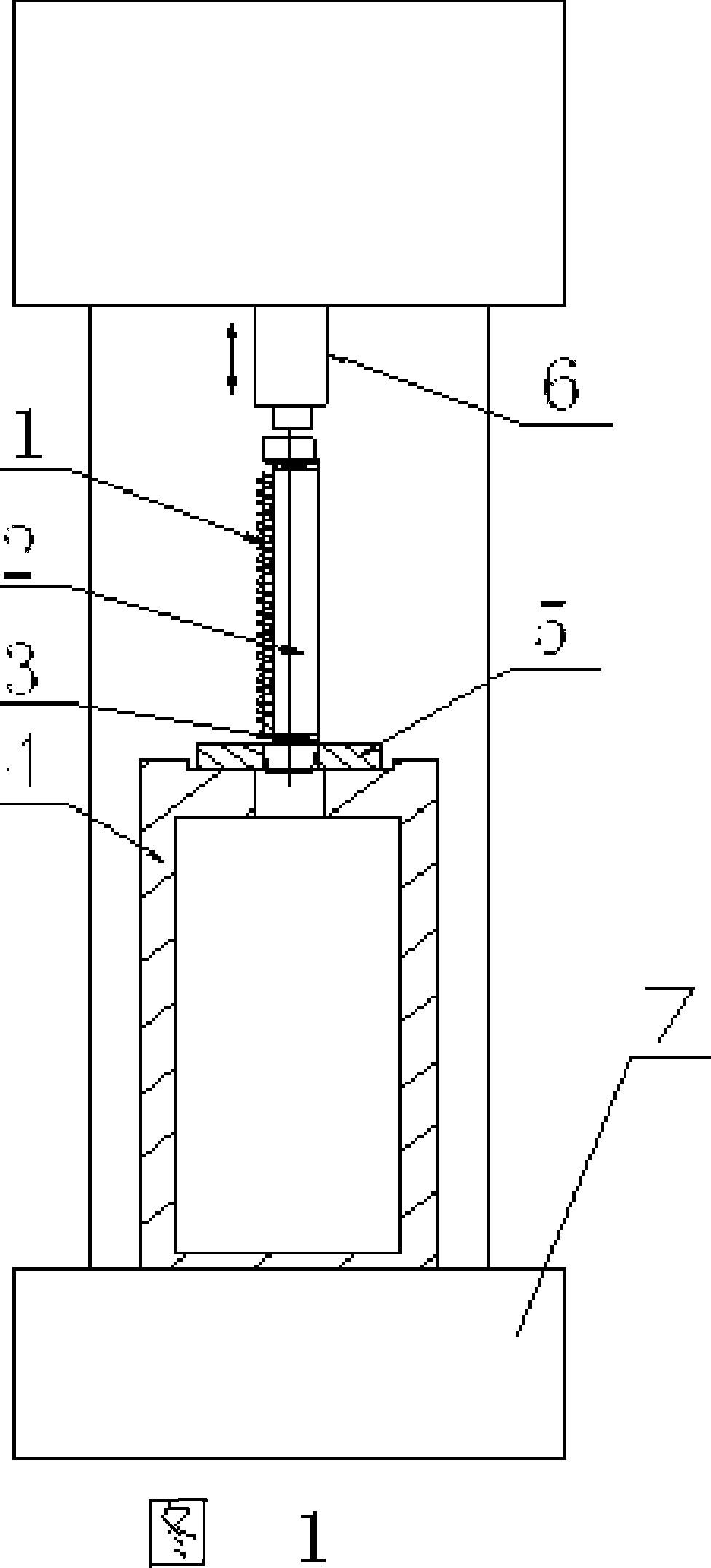

[0023] Embodiment of the present invention: as shown in Figure 1, the process flow of single keyway processing in the inner hole of the gear includes the following steps: fixing the support seat 4 on the workbench 7, placing the workpiece 5 on the support seat 4, and placing the tool of the combined tool Insert the guide part of the tapered surface of the sleeve 2 into the inner hole of the workpiece 5, start the press to make the pressure ejector rod 6 press the pusher 1 of the combined tool through the workpiece 5, release the ejector rod 6 to take off the workpiece 5 and the combined tool, and the keyway processing is completed .

[0024] As shown in Figure 2, the special device for processing the keyway of the inner hole of the gear includes a press and a pressure ejector rod 6. There is a support seat 4 on the press table 7, a workpiece 5 is arranged on the support seat 4, and Combined cutter is arranged between bar 6.

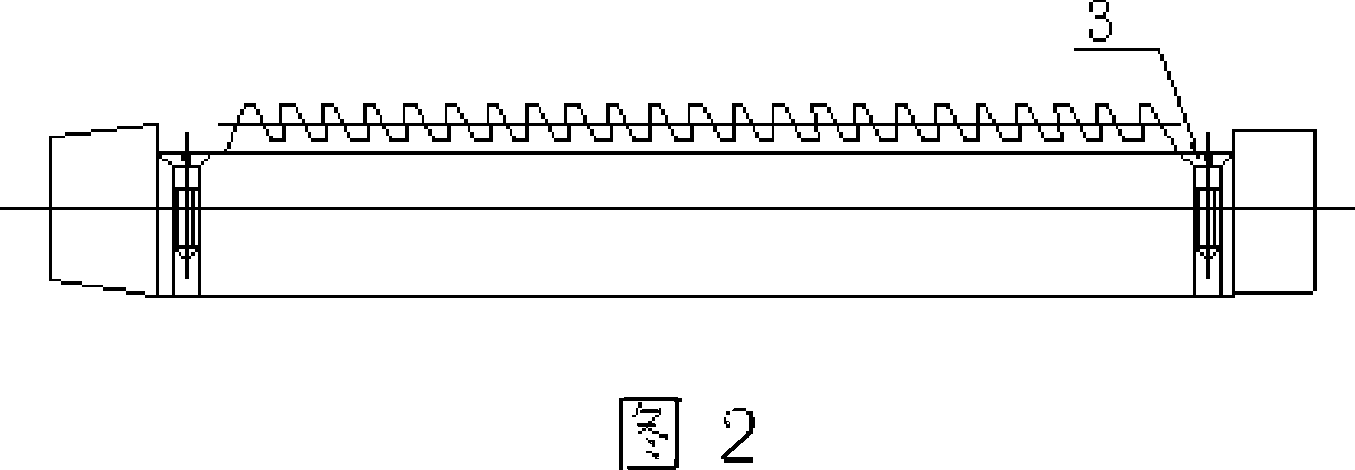

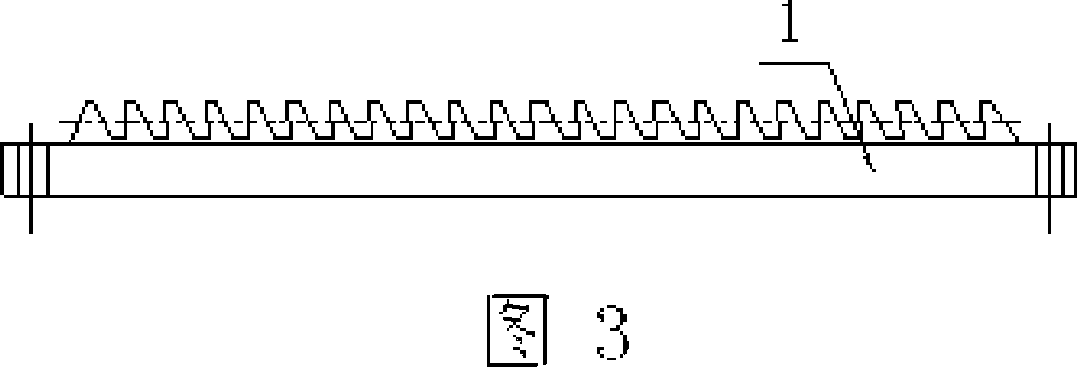

[0025] The combined tool is composed of the push k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com