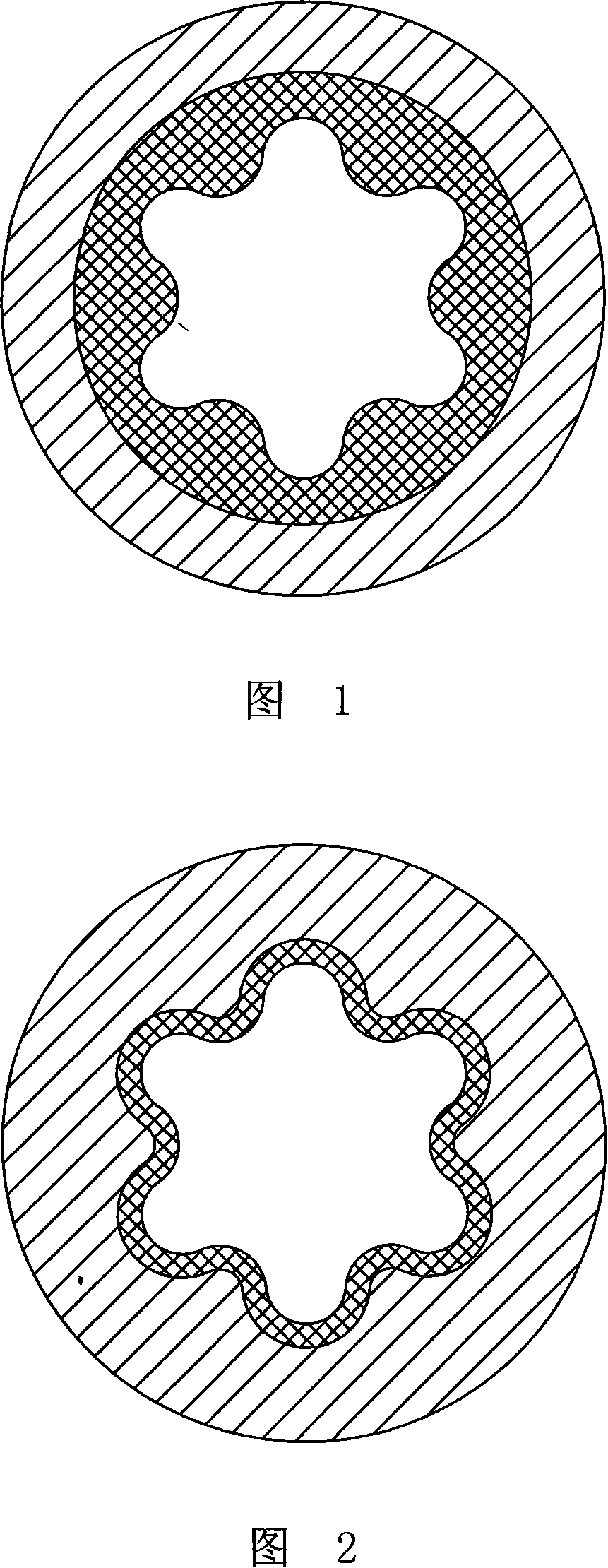

Internal spiral face processing equipment and its processing technology

A surface processing and internal helical technology, applied in the field of internal helical surface processing equipment and its processing technology, can solve the problems of reducing drilling tool power, poor sealing, uneven thickness, etc., to improve work efficiency, improve mechanical properties, increase additional Focus on the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

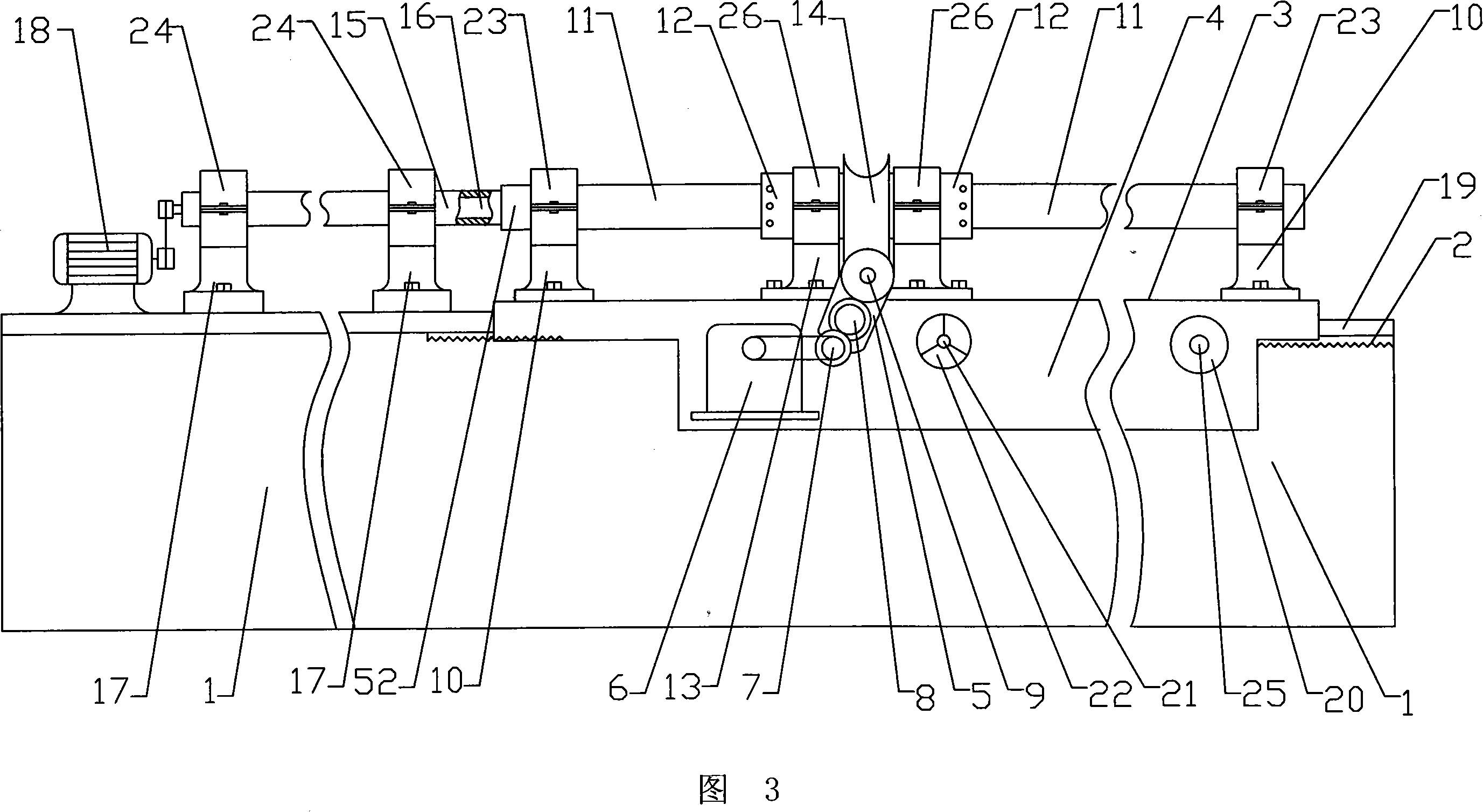

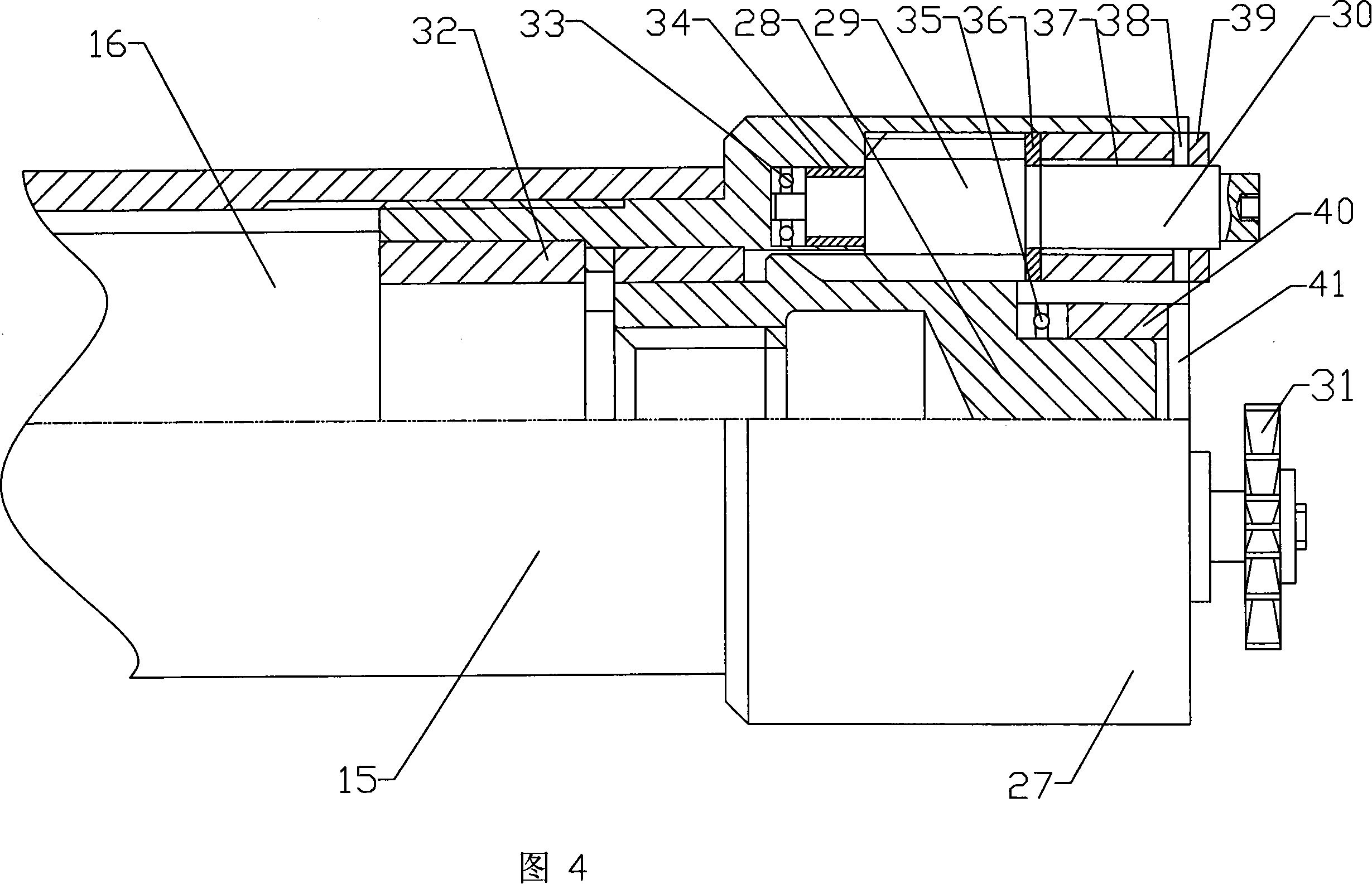

[0037]Embodiment, as shown in Figure 3, the internal helical surface processing equipment includes a milling device and a broaching device, and the milling device includes a bed body 1, and the bed body 1 is provided with a cutter bar 15 and a cutter bar support frame with a cutter 17. The knife bar support frame 17 is provided with a knife bar clamp tile 24, the knife bar 15 is supported and fixed by the knife bar clamp tile 24 installed on the bed body 1, and a transmission shaft 16 is arranged inside the knife bar 15, and the end of the transmission shaft 16 It is connected with the tool, and the other end is connected with the motor 18. The bed body 1 is provided with a carriage 3 and a floating surface guide rail 19. Both sides of the carriage 3 have protective plates 4 perpendicular to the plane of the carriage 3. The carriage 3 is installed on the floating surface. On the guide rail 19, the carriage 3 is provided with a turbine 14 and a turbine bracket 13, the turbine 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com