Milling cutter and cutting insert therefor

A technology for cutting inserts and milling cutters, used in milling cutters, forming cutters, linear broaches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

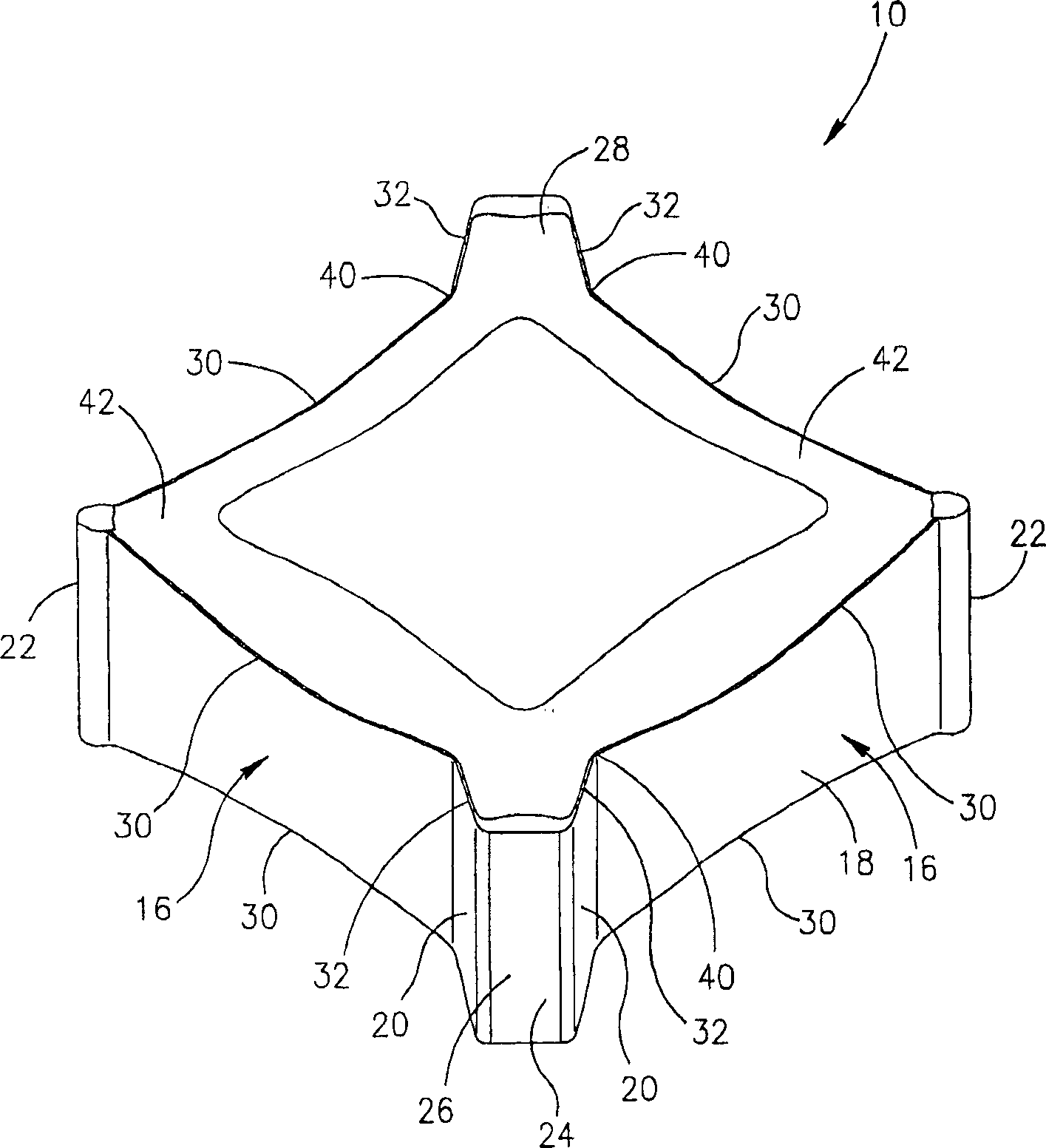

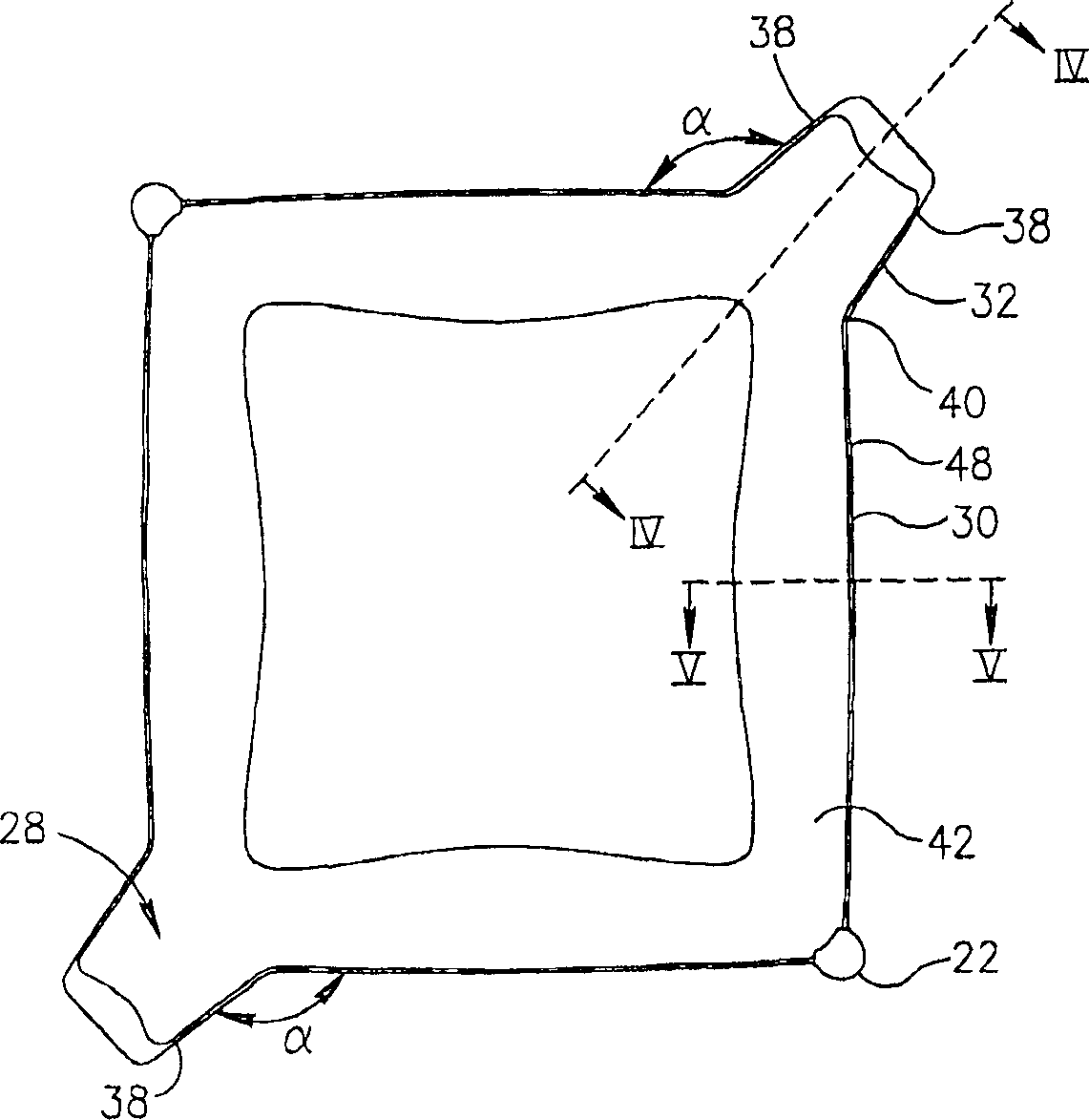

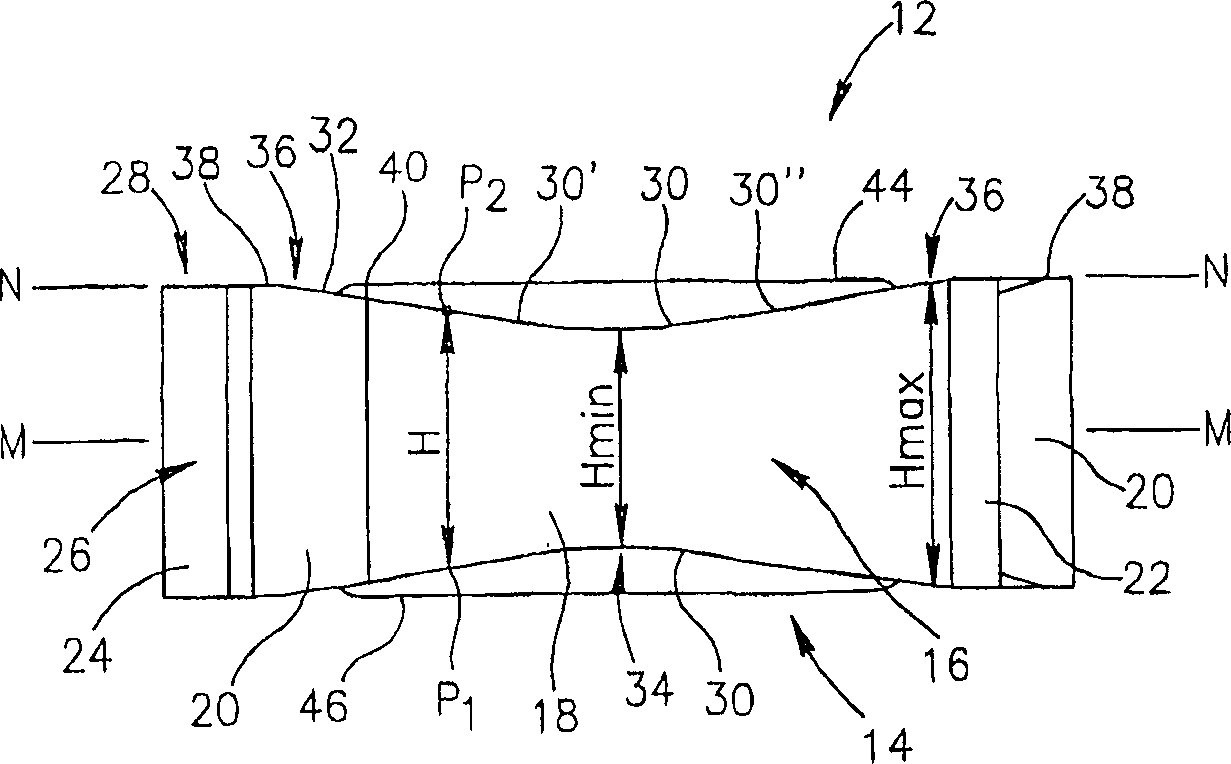

[0043] see Figure 1~3 . The cutting insert 10 of the present invention has a top surface 12 and a bottom surface 14 that are generally square. The cutting insert can be pressed and sintered, or it can be injection molded. Four identical general sides 16 extend between the top surface 12 and the bottom surface 14 . The sides 16 are identical in design, but one or more sides may differ slightly from the desired design due to the manufacturing process. For example, as is known, cutting inserts shrink during sintering, which shrinkage may not be uniform. Therefore, it is possible to obtain identical cutting inserts taking into account manufacturing tolerances. Each side 16 includes a major side 18 connected to an adjacent minor side 20 . Adjacent main sides 18 meet at two diametrically opposite corner edges 22 .

[0044] Adjacent secondary sides 20 meet at a medial side 24 . The two adjacent secondary flanks 20 and the intermediate flank 24 form a peripheral flank 26 of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com