Push-type broach

A cutting edge and quadrilateral technology, applied in the field of push knives, can solve the problems of increasing the manufacturing cost of push knives, difficult machining, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

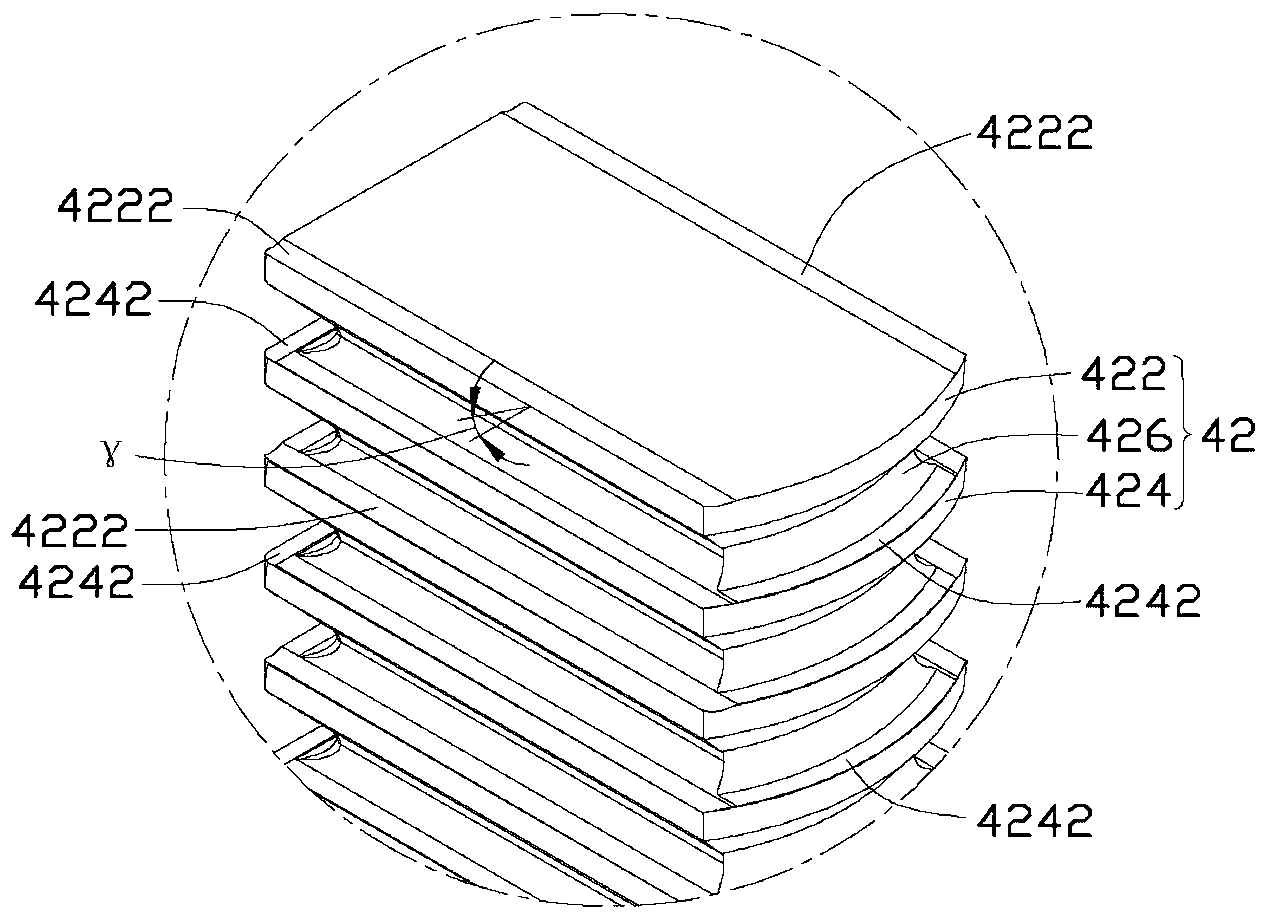

[0013] The push knife according to the embodiment of the present invention will be further described in detail below with reference to the specific implementation method and the accompanying drawings.

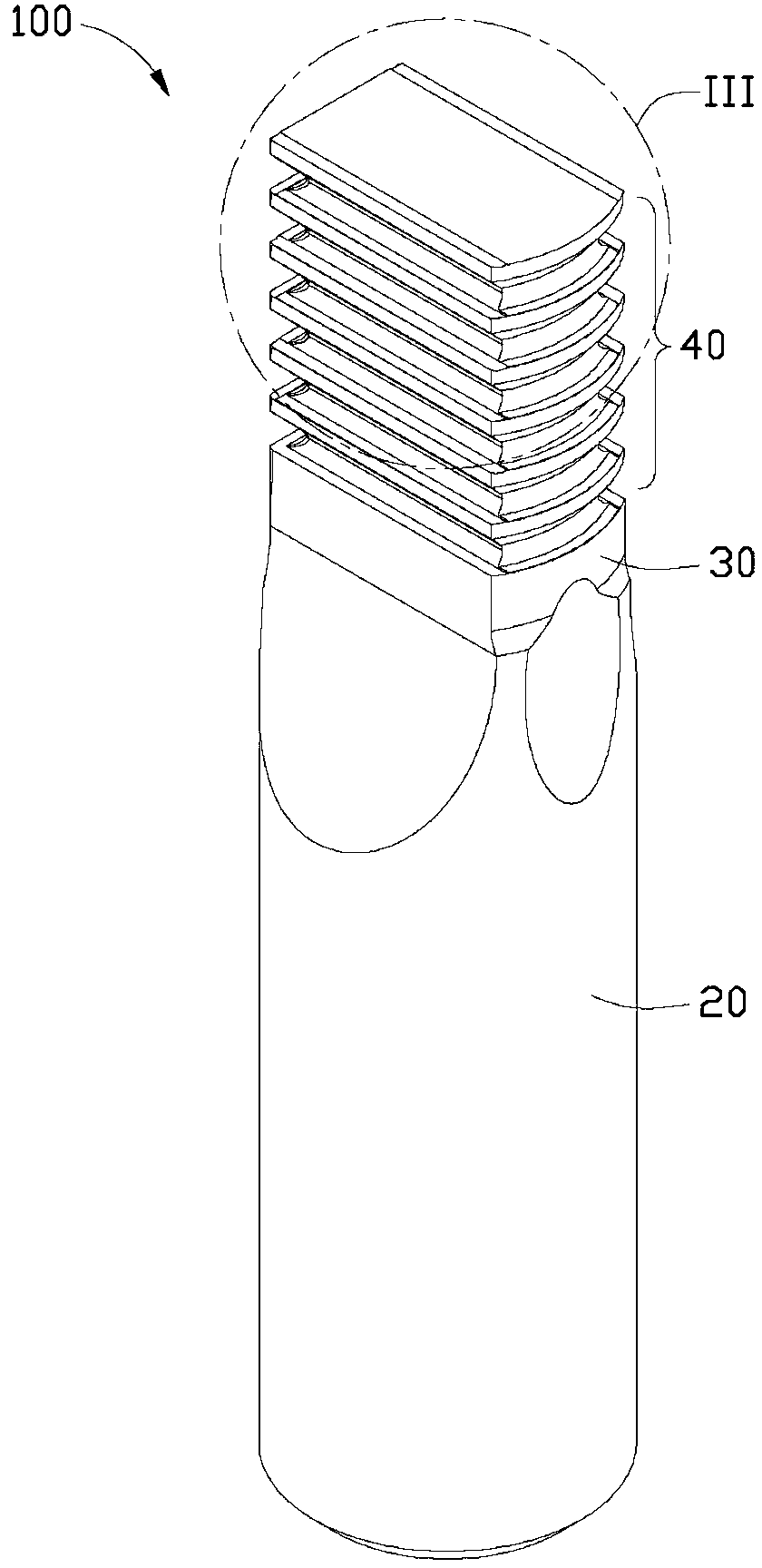

[0014] A push knife according to an embodiment of the present invention is used for finishing a prefabricated hole in a metal substrate. When processing a hole on a metal substrate, the prefabricated hole is first stamped on the metal substrate by a drill bit and other equipment. At this time, the inner surface of the prefabricated hole is rough and its aperture is smaller than that of the subsequent hole processed by a push knife. The push knife finishes the prefabricated hole to remove the machining allowance, and finally processes a hole with a smooth surface and a predetermined size and shape.

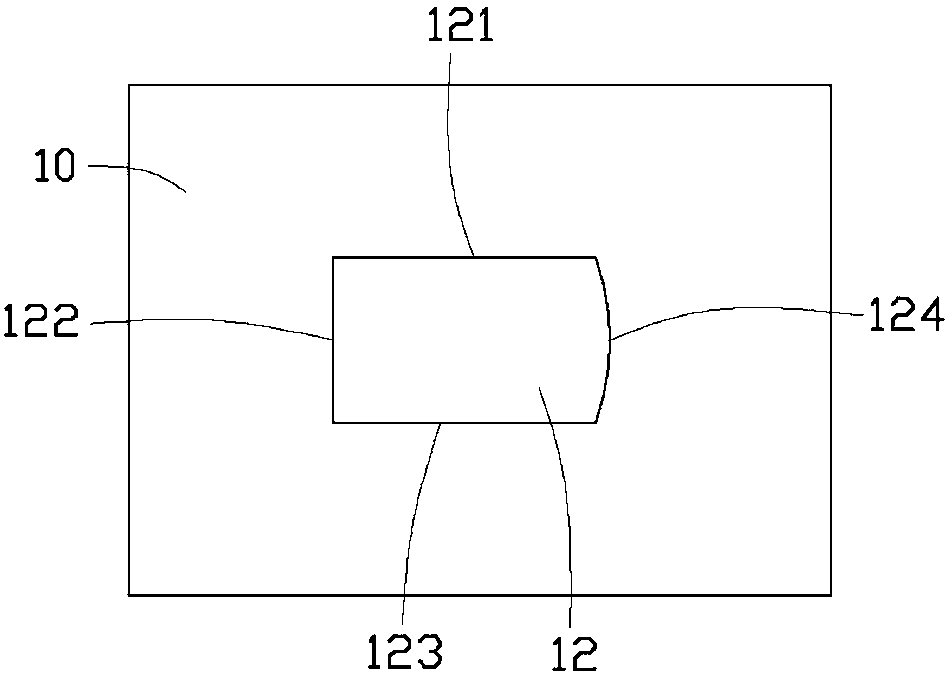

[0015] see figure 1 and figure 2 , the push tool 100 according to the embodiment of the present invention is used to process the hole 12 on the aluminum alloy workpiece 10 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com