Internal broaching machine and internal broach

a broaching machine and internal technology, applied in the field of internal broaching machines, can solve the problems of inability to correct cutting by the broach, inability to improve the broaching accuracy of conventional construction, and adverse effect on the life of the broach, so as to achieve high broaching accuracy and improve the machining accuracy of the workpi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

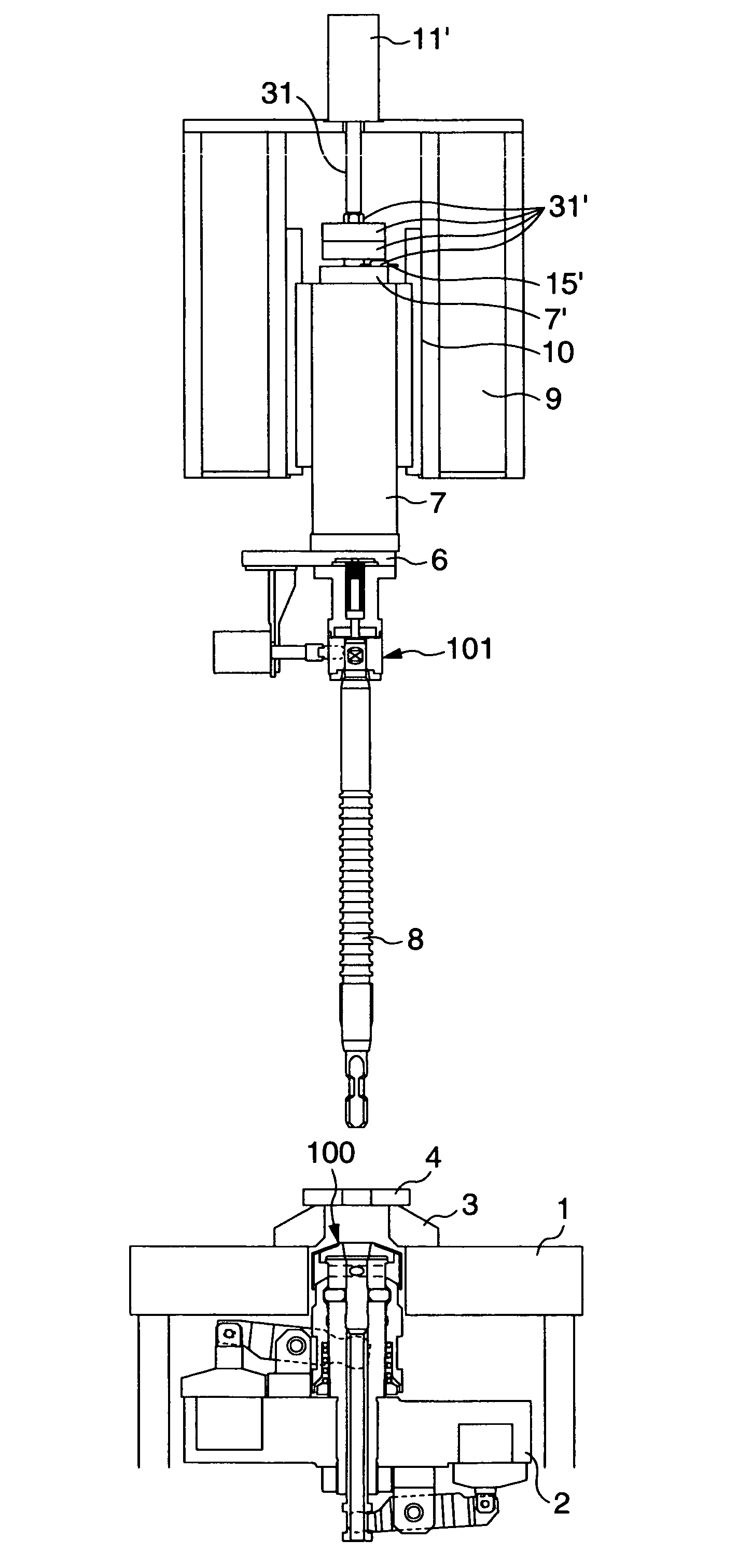

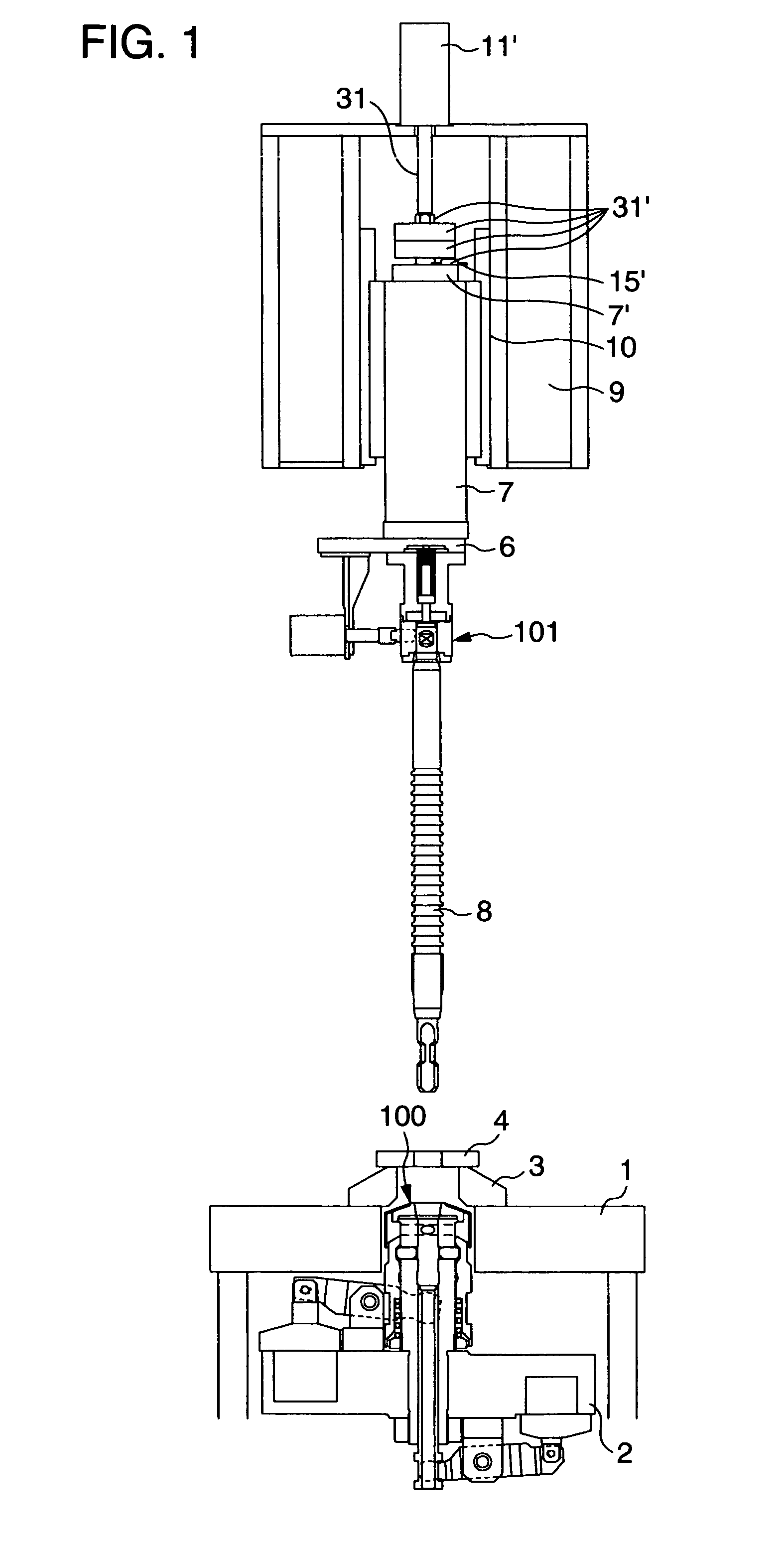

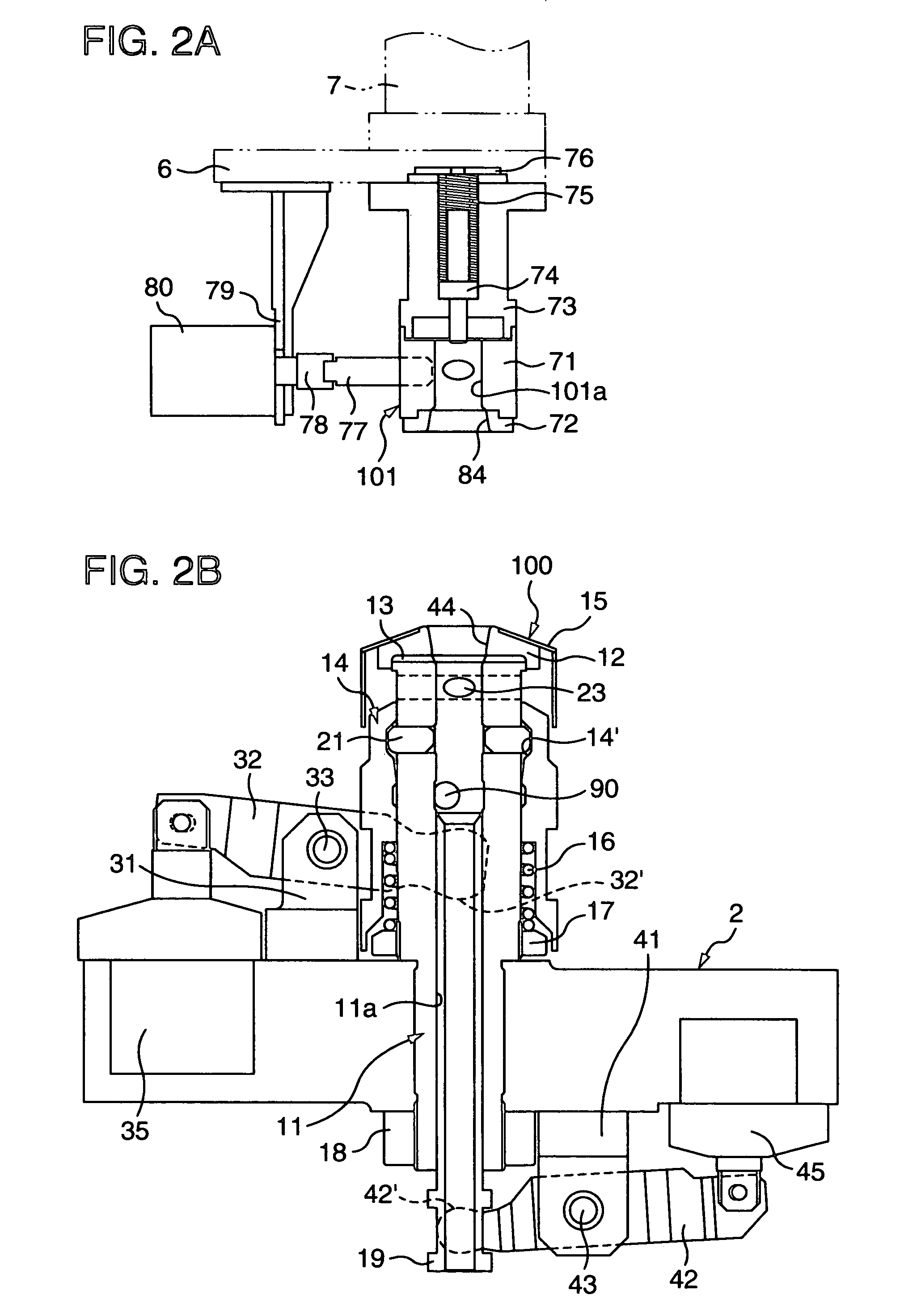

[0038]FIG. 1 illustrates an essential portion of the internal broaching machine according to an embodiment of the invention. The machine of this example is a broach-moving, work-fixed type broaching machine.

[0039]FIG. 1 shows a pull head 100 for gripping a front shank or pull end of the broach and a retrieving head 101 for gripping a rear shank or follower end of the broach. In this embodiment, the pull head 100 has a two-claw direction determination mechanism using claw members similar to those of the conventional art described above, and the retrieving head 101 is of a pin type.

[0040]The broaching machine shown in FIG. 1 is in a state that the pull head 100 is in unclamping, the retrieving head 101 is suspending the broach 8 and a workpiece 4 is placed on an upper surface of a reference jig plate 3. The reference jig plate 3 that receives the workpiece 4 is secured to a column 1 at a front of a machine body.

[0041]A slide table 2 for the pull head 100 is arranged vertically movable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com