Internal broaching tools

A tool, rough drawing technology, applied in the direction of manufacturing tools, gear teeth manufacturing tools, broaches, etc., can solve the problem that the side shape can no longer be corrected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

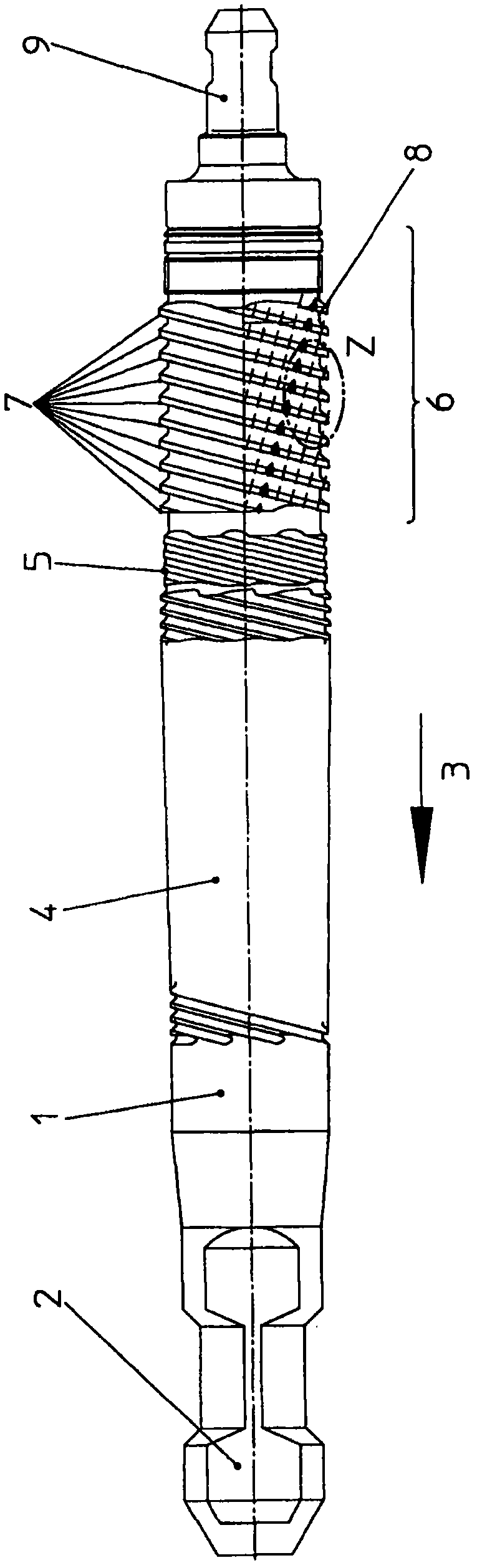

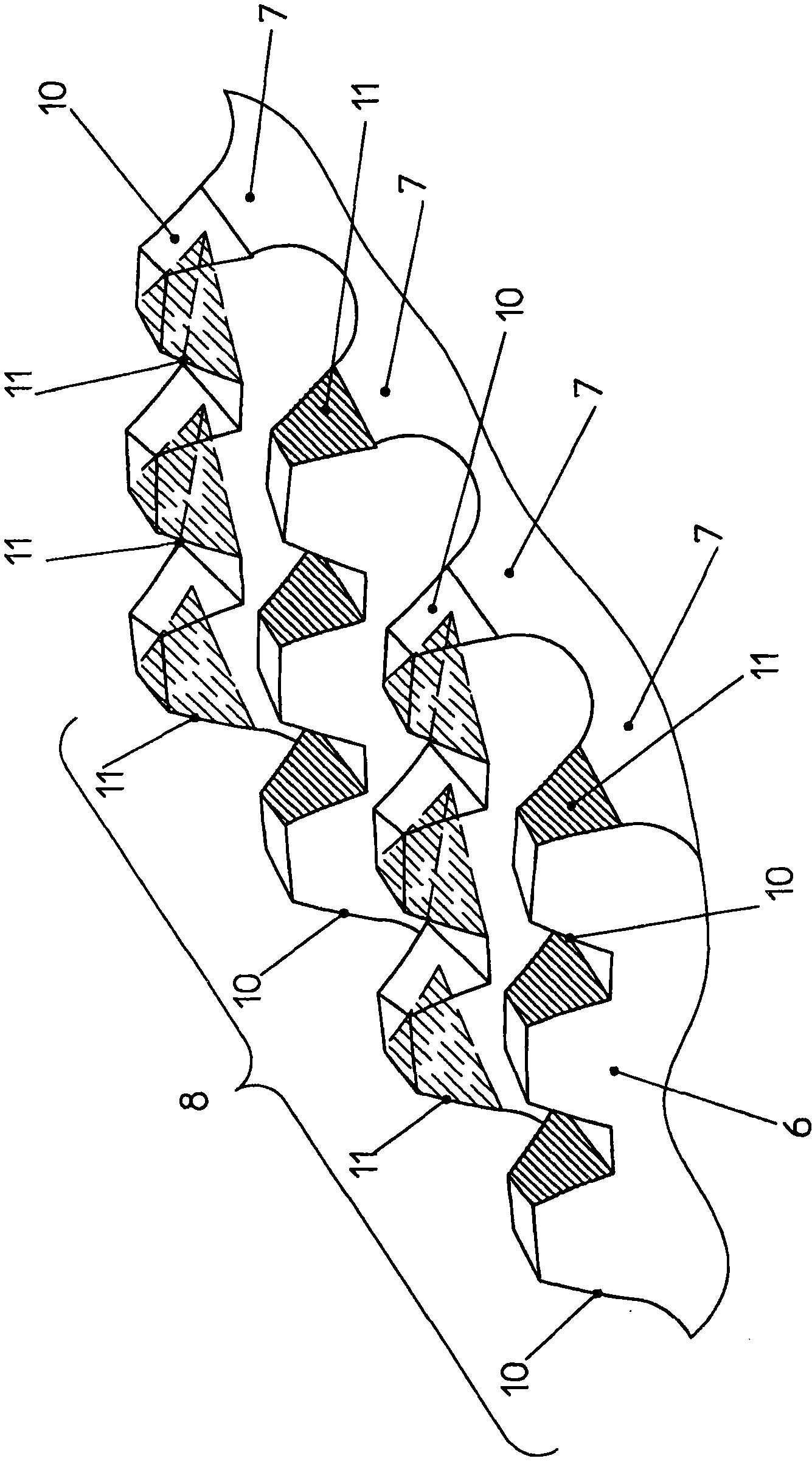

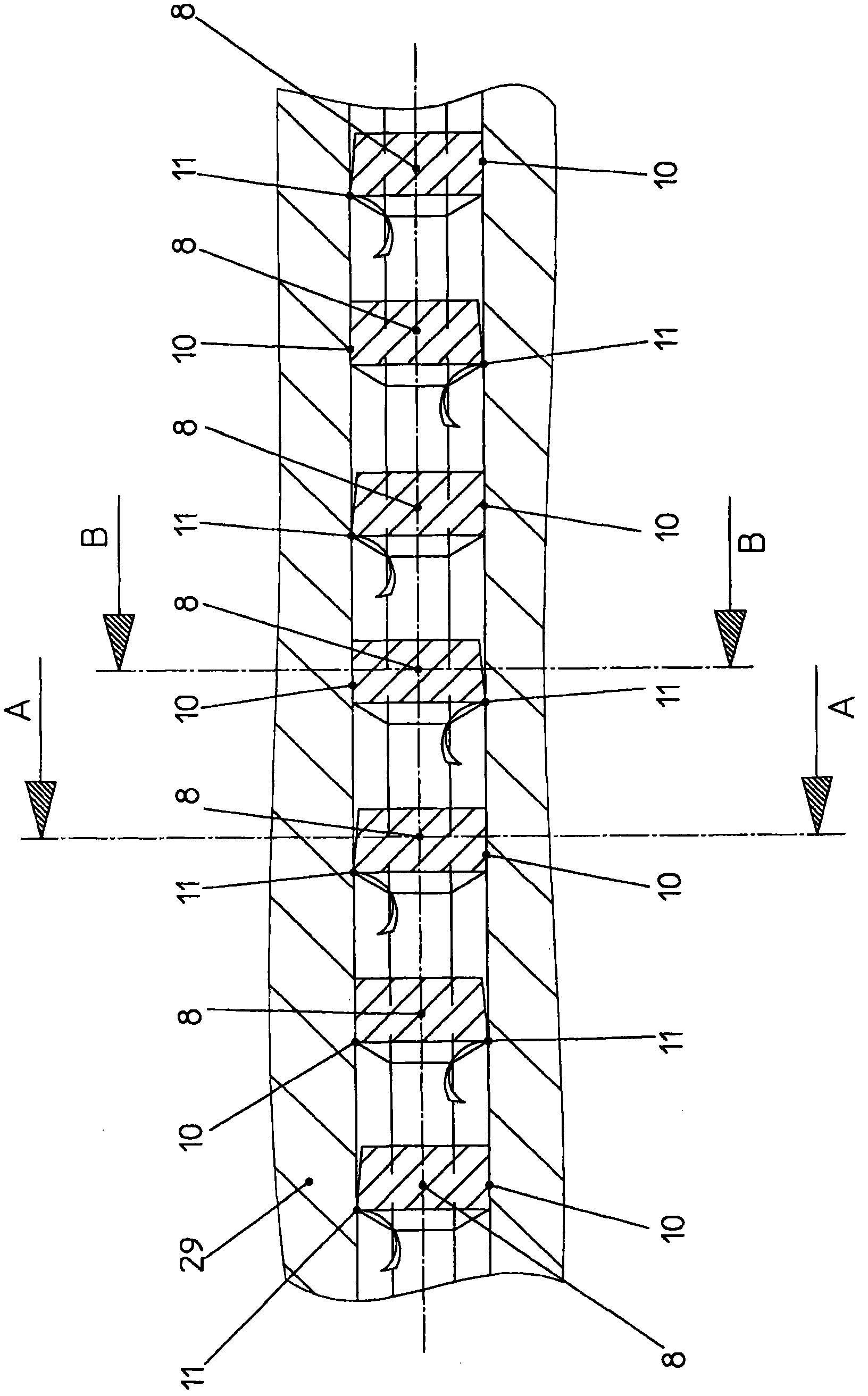

[0057] exist figure 1 shows an internal broaching tool 1 according to the invention for internal broaching of an internal toothing with a profile base and a profile side, the internal broaching tool 1 comprising: a shank 2; opposite to the broaching direction 3 A toothed part 4 arranged adjacent to the shank 2 with a plurality of broaching teeth arranged in succession in a row (Reihen) with contour base edges associated with one another for pre-broaching (rough broaching) profile; opposite to the broaching direction 3 there follows a correcting part 6 with a plurality of correcting broaching teeth 8 arranged successively in a row 7; An unloading section 5 is arranged between the correction section 6 and the correction section 6 .

[0058] This arrangement according to the invention of the unloading part 5 unloads the workpiece before corrective machining, so that the deformation of the workpiece caused by the cutting forces occurring during broaching is not eliminated after t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com