Helical broach

A technology of helical broach and spiral groove, applied in the direction of broach, linear broach, broaching machine, etc., can solve the problems of poor tooth line accuracy, not pulling out at the same time, unstable movement, etc., and achieve the effect of excellent accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

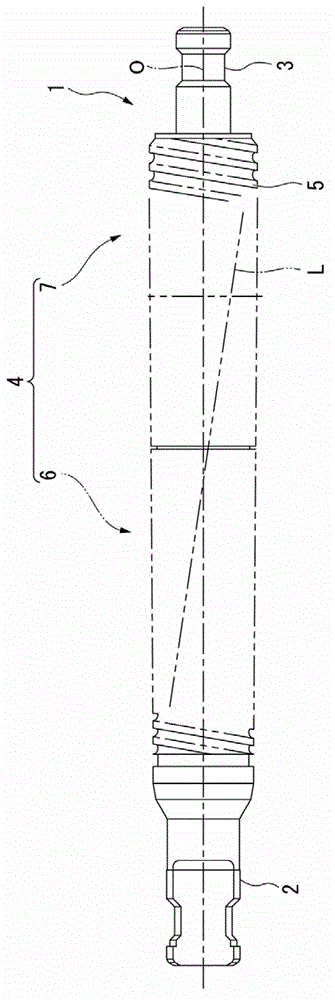

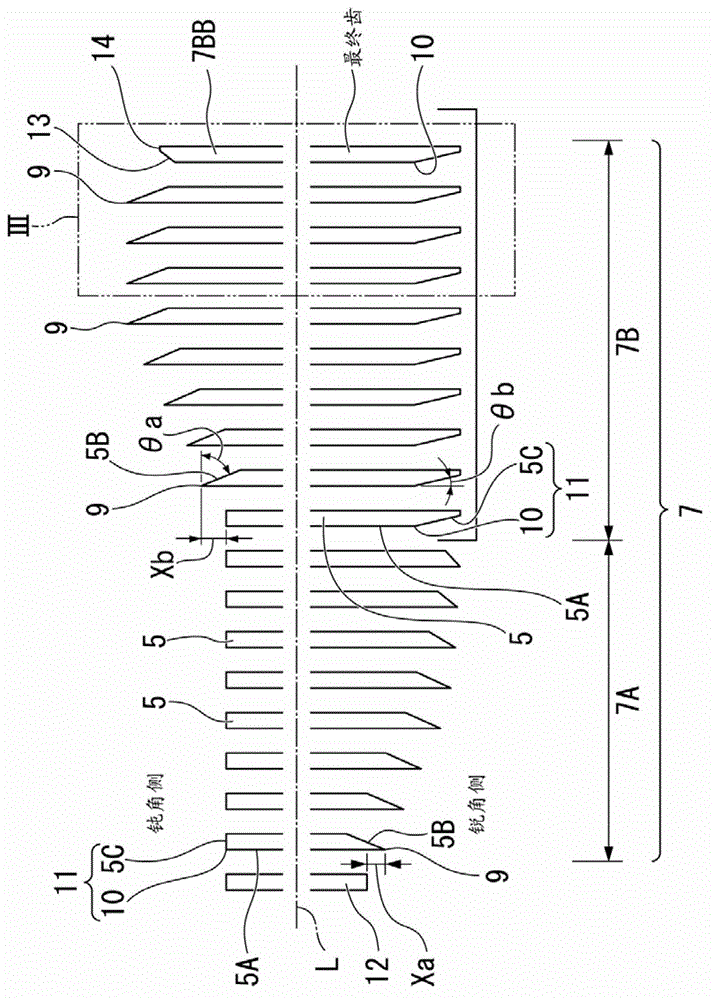

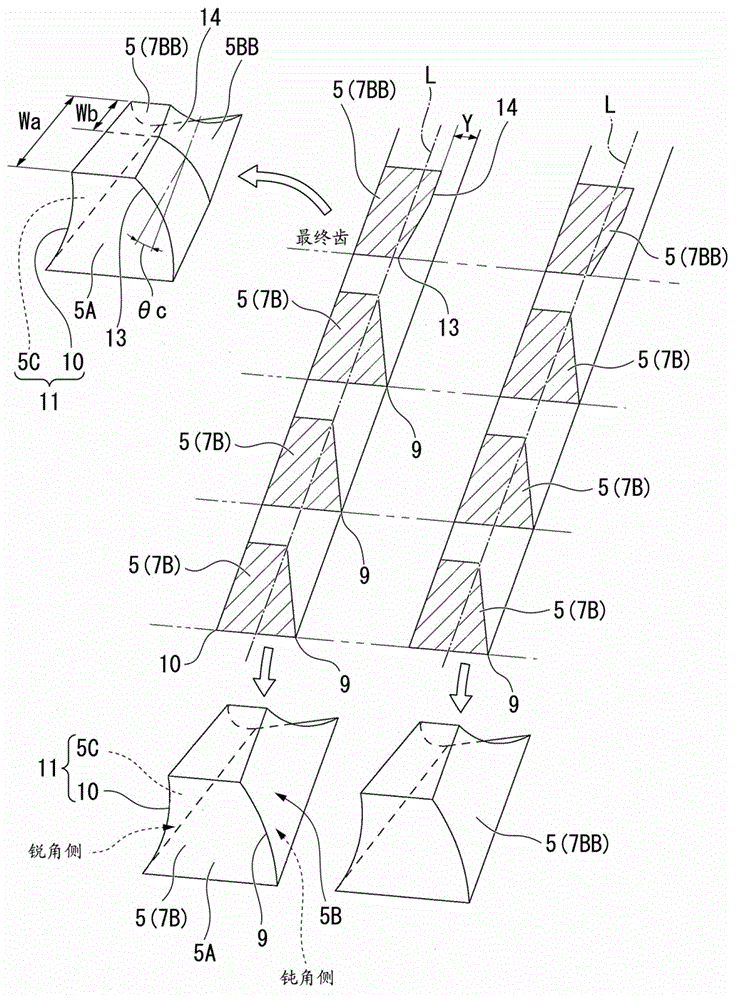

[0040] Figure 1 to Figure 4 An embodiment of the integrated helical broach of the present invention is shown. figure 1 It is a side view showing an embodiment when the present invention is applied to a helical broach. The helical broach of the present embodiment broaches a workpiece in order to manufacture a helical internal gear such as a planetary internal gear having a helical groove on the inner periphery described above, for example. Such as figure 1 As shown, the broach main body 1 is in the shape of a long bar with the axis O as the center. Clamping portions 2 and 3 are formed at both end portions of the broach main body 1 . A cutting tooth portion 4 is formed between the clamping portions 2 , 3 . In this cutting tooth portion 4, a plurality of cutting teeth 5 protruding radially outward from the outer circumference of the broach main body 1 are formed from the front end side of the broach main body 1 ( figure 1 on the left side) to the rear end side ( figure 1 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com