Arc-extinguishing chamber, arc-extinguishing chamber tank and high-voltage switching equipment applying this arc-extinguishing chamber

A technology of arc extinguishing chambers and tanks, which is applied in the field of high-voltage switchgear and arc extinguishing chambers. It can solve the problems of weak insulation capacity of end caps, achieve ideal insulation performance, improve deposition conditions, and avoid damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

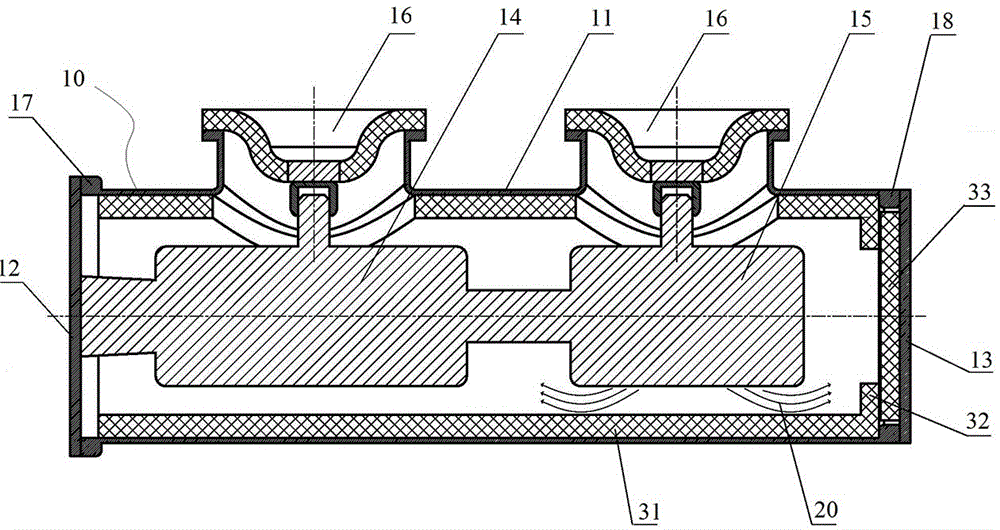

[0031] An example of an arc extinguishing chamber in the present invention is figure 1As shown, it is mainly composed of a tank body 10 , a moving end assembly 14 , a static end assembly 15 and an insulating flange 16 arranged at the inlet and outlet of the tank body 10 . The tank body 10 is made of metal, including a tank body 11 and a solid insulating layer arranged on the inner wall of the tank body 11. The tank body 11 includes a cylinder part extending in the left and right direction and shafts respectively sealed on the cylinder part. To the moving end cover part 12 and the static end cover part 13 at both ends, the end cover parts at both ends are fixed on the cylinder part through the flange structure, and the flange structure includes the outer flange 17 and the setting Inner flange 18 at the right end of the barrel portion. The moving end ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com