Systems and methods for maintaining sulfur concentration in a syngas to reduce metal dusting in downstream components

a technology of sulfur concentration and downstream components, which is applied in the direction of combustible gas production, combustible gas purification/modification, chemistry apparatus and processes, etc., can solve the problems of metal dusting in downstream components such as exchanger tubes, metal dusting also known as carburization, and the sulfur level in these gasifier feeds can be below the minimum level of sulfur needed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010]Systems and methods for maintaining a sulfur concentration in a syngas are provided. The method can include combining sulfur and a carbonaceous material to produce a sulfur containing carbonaceous feed. The method can also include gasifying at least a portion of the sulfur containing carbonaceous feed to produce a syngas and detecting a sulfur concentration in the syngas. The method can also include adjusting an amount of the sulfur combined with the carbonaceous material based on the detected sulfur concentration.

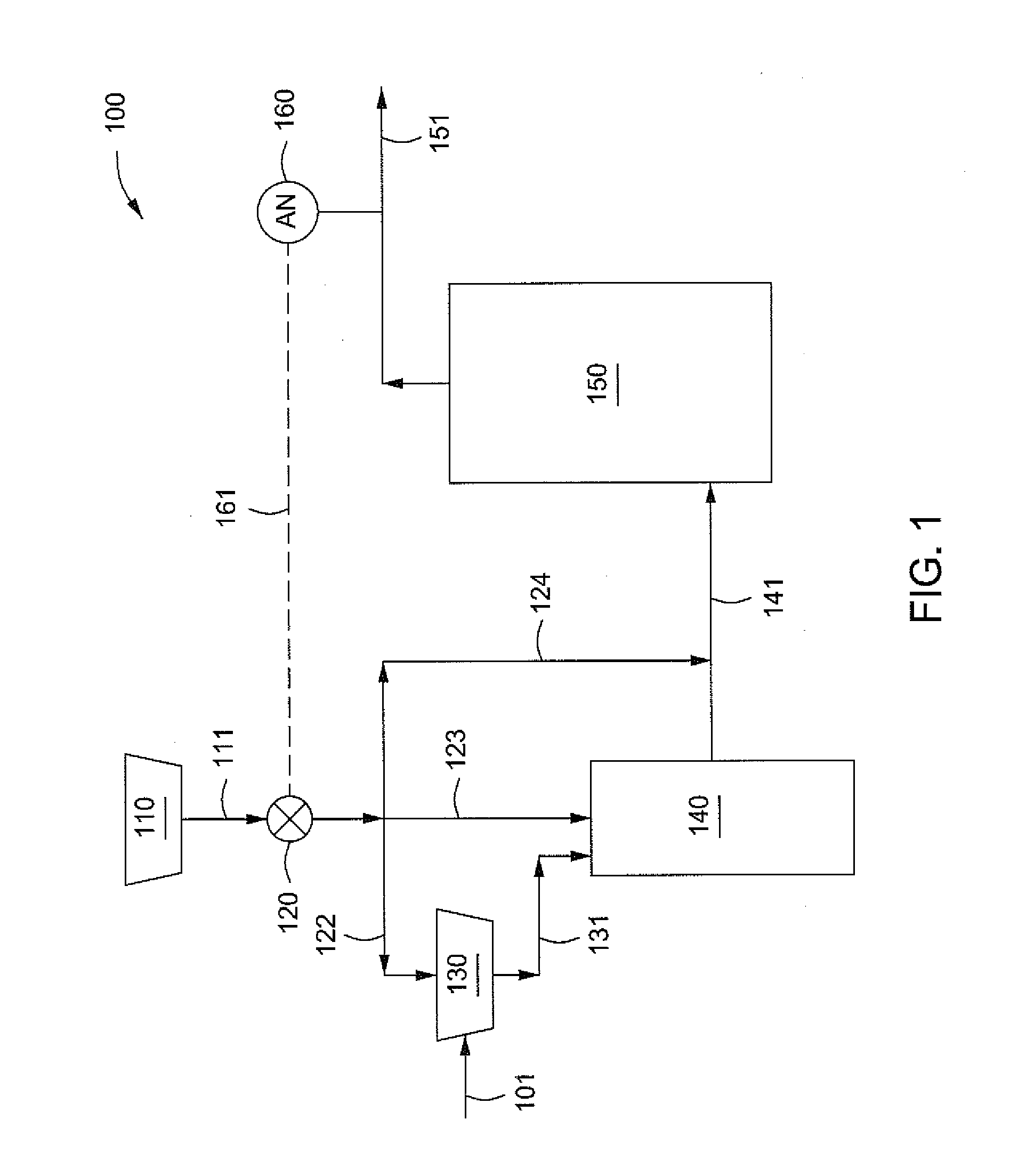

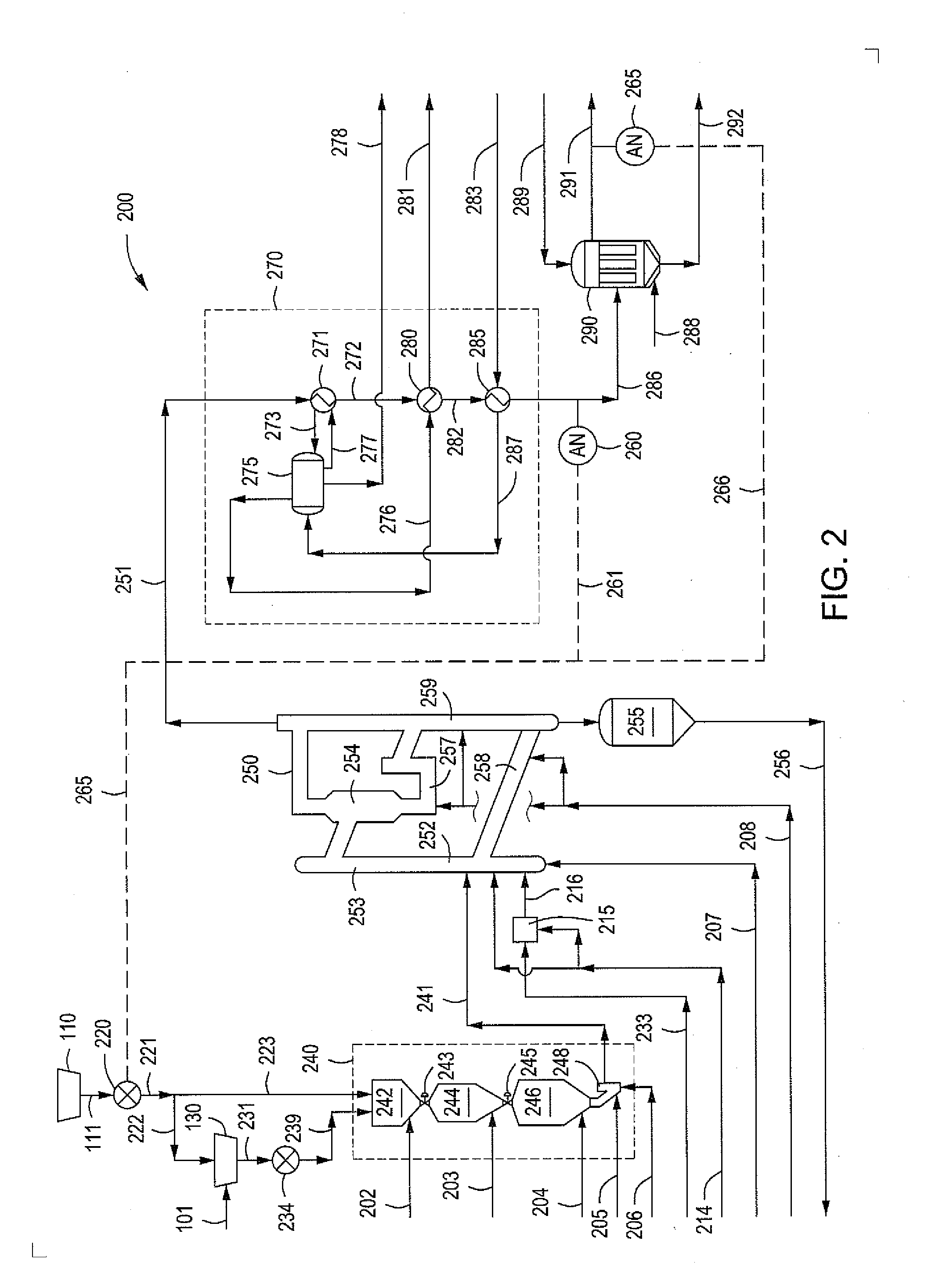

[0011]FIG. 1 depicts a schematic of an illustrative gasification system 100 for producing a syngas via line 151 having a sulfur concentration sufficient to reduce metal dusting in components downstream of a gasifier 150, according to one or more embodiments. The gasification system 100 can include one or more lock hoppers or storage bins 110, 130 for feeding one or more gasifier feed systems 140, wherein the gasifier feeds can be stored or treated prior to entering t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com