Cooling ring for welding bellows generating less metal powder

A bellows and cooling ring technology, applied in the field of cooling rings for bellows welding, can solve the problems of inconvenience and difficulty in removing copper dust and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

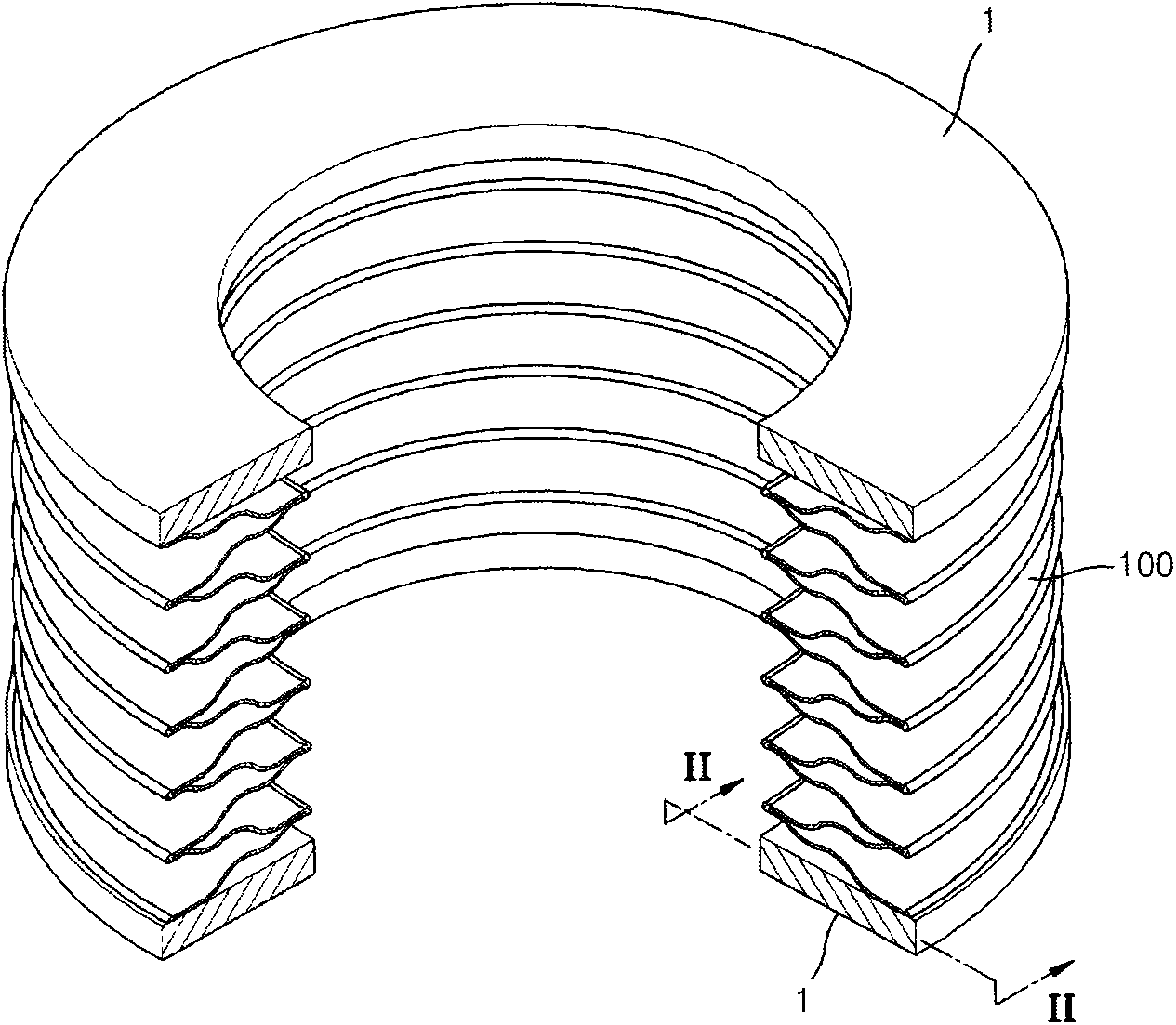

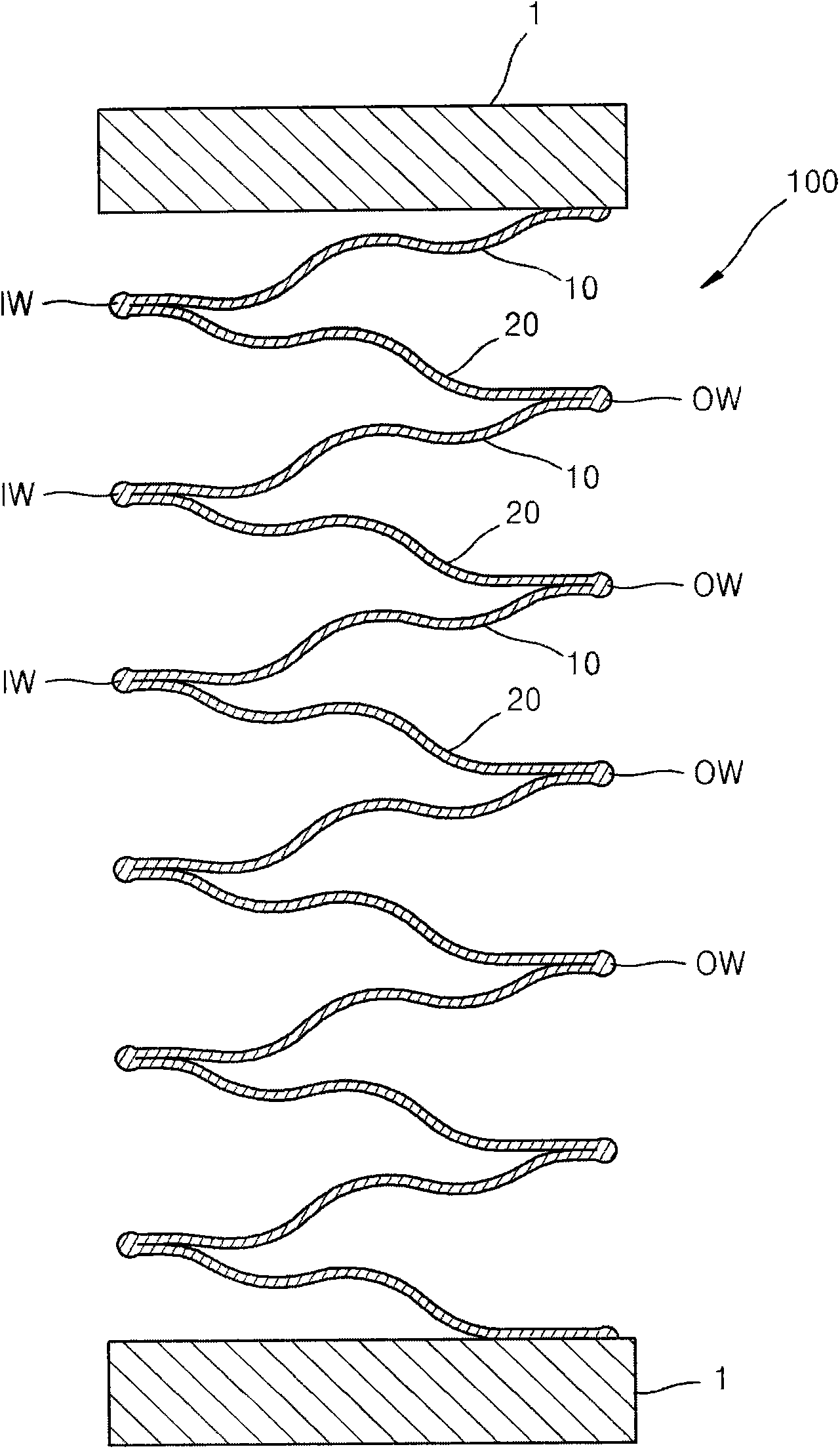

[0039] Figure 7 It is a plan view of the cooling ring for bellows welding according to the first embodiment of the present invention, Figure 10 It is a figure which shows the cross section of the cooling ring for bellows welding of 1st Example of this invention.

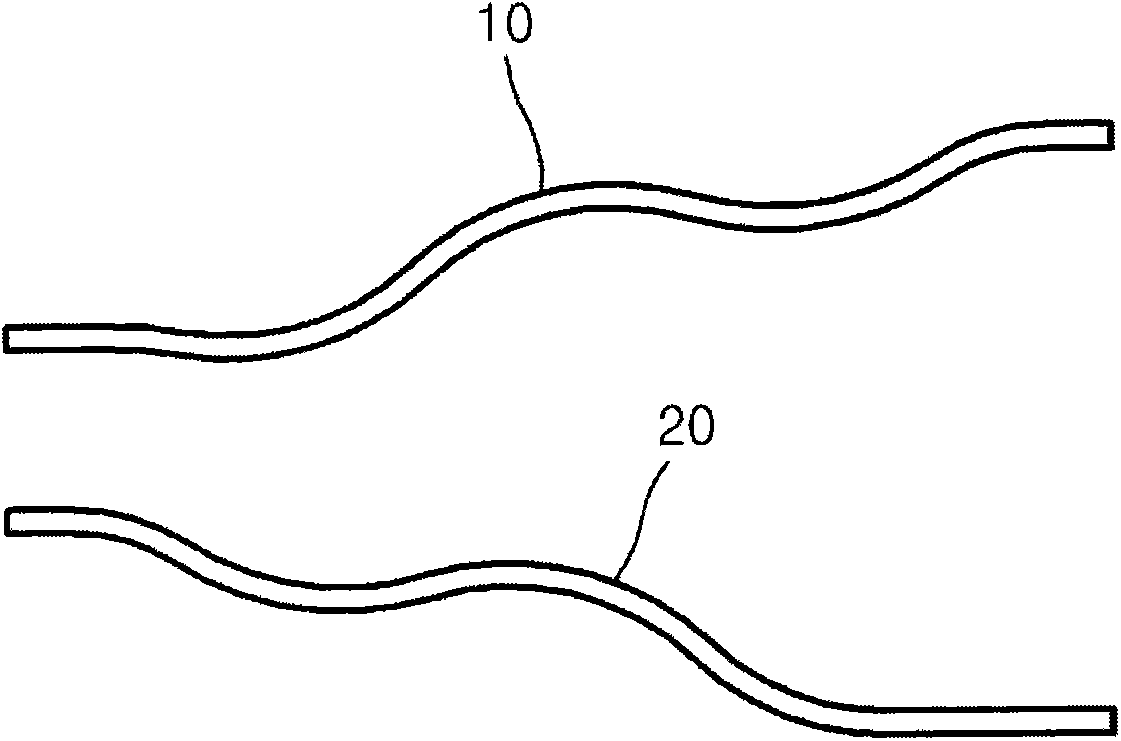

[0040] refer to Figure 7 and Figure 10 , the bellows welding cooling ring 30 of the preferred embodiment of the present invention is used to manufacture the bellows 100 welding cooling ring, such as figure 1 As shown, in a state of being in contact with at least one of the first diaphragm 10 and the second diaphragm 20, it is embedded between the first diaphragm 10 and the second diaphragm 20, so that the first diaphragm 10 and the second diaphragm 20 are mutually snug. The cooling ring 30 for bellows welding includes a main body 35 and a gold-plated layer 36 .

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com