Method of protecting equipment against corrosion at high temperature

An equipment, high temperature technology, applied in the field of protecting equipment from corrosion at high temperature, can solve problems such as failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

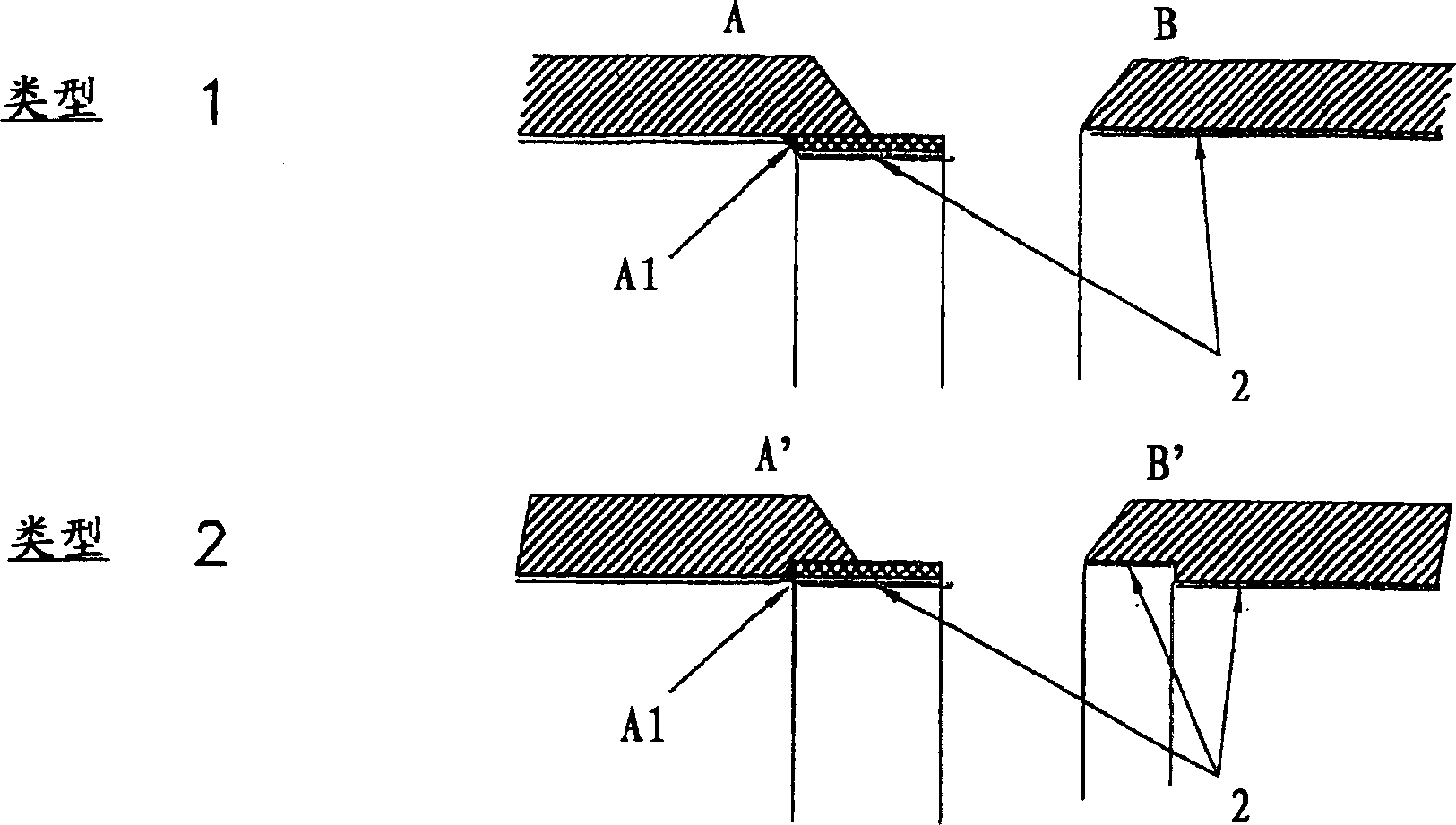

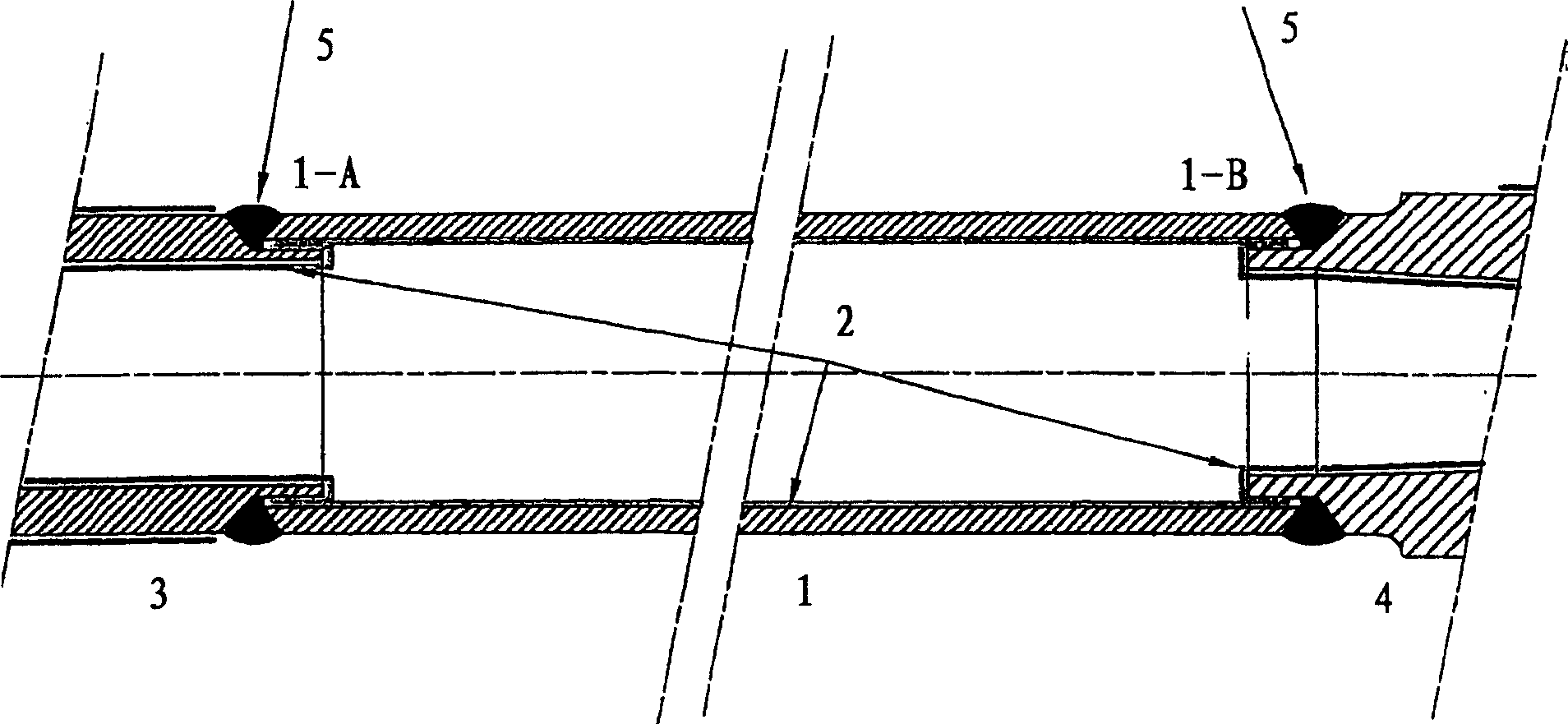

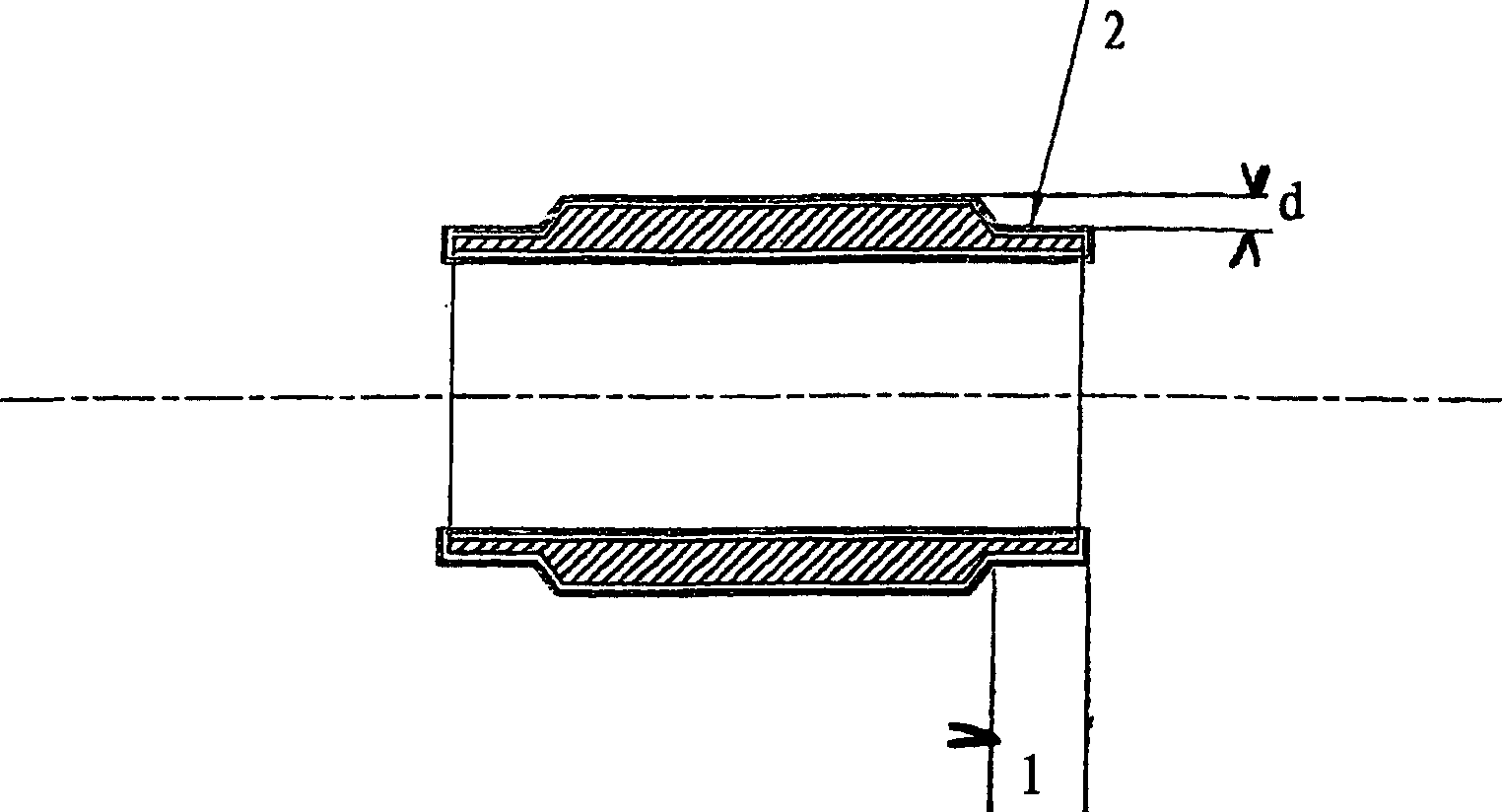

[0029] figure 1 Two conventional connection types with support bars are shown. In both cases, the system parts and the support bars to be connected are already protected by aluminizing at least in the regions that are to be corroded.

[0030] According to connection type 1, a support bar is located on the inner surface of the device and protrudes from this surface, this support bar is welded to the end A of the device at point A1, the chamfered end B of the device is designed to be chamfered with itself The ends A of the device are in contact; then, the two ends are welded on their outer surfaces. This conventional solution has two drawbacks in particular:

[0031] - the welding zone A1 is difficult or even impossible to form in pipes with a diameter of less than 100 mm using current means;

[0032] - In the welding area A1, especially in areas associated with different materials and structures, the protective layer is defective, presenting the risk of causing metal dusting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com