Method for controlling defrosting operation of air-conditioner

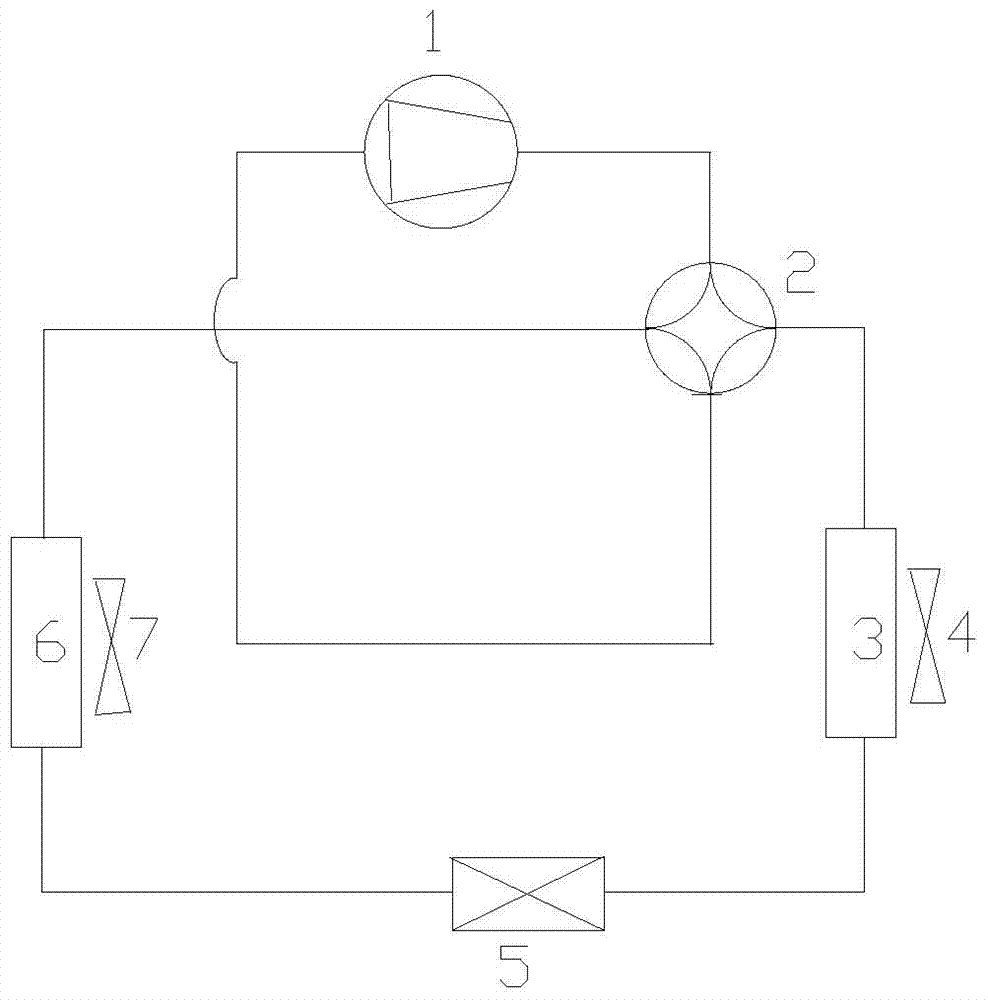

A technology of operation control and air conditioner, which is applied in the direction of control input involving air characteristics, space heating and ventilation control input, heating and ventilation control system, etc. It can solve the problems of attenuation of heating capacity and inability to flow outside the condenser, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

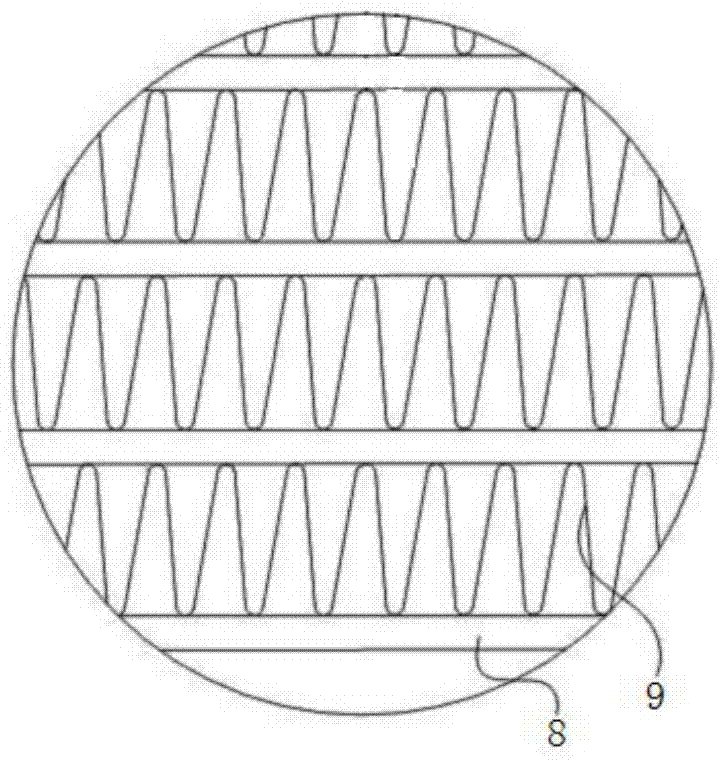

[0031] like Figure 4 As shown, in this embodiment, a defrosting operation cycle is divided into multiple stages. In order to facilitate control and simplify the control program, it is preferable to divide the defrosting operation cycle by time, that is, to divide a defrosting operation cycle into multiple time periods, and multiple The times of the time segments are respectively T1, T2, T3, . . . , Tn.

[0032] A defrosting operation cycle is about 6-15 minutes, generally 9-10 minutes. Therefore, it is preferable to divide a defrosting operation cycle into two to five time periods from the beginning to the end, and it is best to divide it into three time periods to avoid As a result, the outdoor condensing fan 4 frequently reverses in a short period of time, and the three time periods are the first time period T1, the second time period T2 and the third time period T3.

[0033] Wherein, the condition to be satisfied in the setting of the first period T1 is to make all or at ...

Embodiment 2

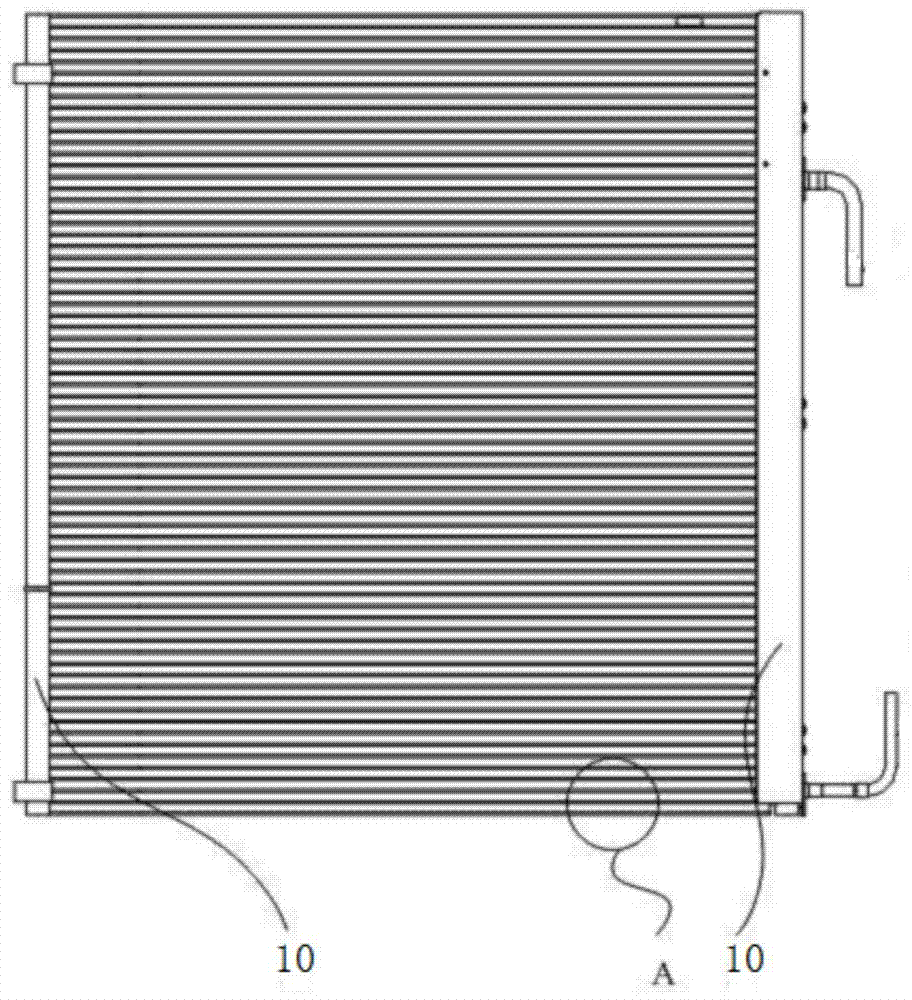

[0048] The difference from Embodiment 1 is that the entire defrosting operation cycle is not divided into multiple time periods, but only at the end of defrosting, the outdoor condensing fan 4 is controlled to run in reverse at a high speed. The water will slide down along the condenser 3. At the end of defrosting, use the outdoor condensing fan 4 to run in reverse at a high speed to blow out the water that remains on the condenser 3 and cannot slide down at one time. In order to avoid frosting or condensation again in this process , the compressor 1 does not stop running, and the time for the reverse operation of the outdoor condensing fan 4 is not easy to be too long, and is limited within 10-50 seconds, preferably controlled between 15-30 seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com