Comprehensive test device for joint sealing and hydraulic circulating of pipe body

An experimental device and tube body technology, applied in the direction of using liquid/vacuum to measure liquid tightness, applying stable tension/pressure to test material strength, etc., can solve the problem of reducing equipment utilization, failing to adapt to test requirements, and occupying a large area Site and other issues to achieve the effect of improving reliability, improving equipment utilization, and improving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

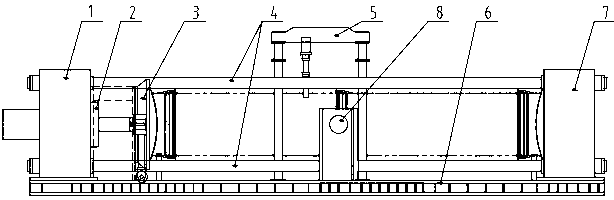

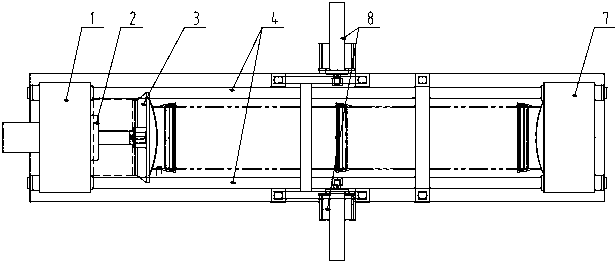

[0016] According to attached figure 1 and 2 It can be seen that the present invention specifically discloses a comprehensive experimental device for pipe joint sealing and hydraulic circulation, which is mainly used for the sealing performance detection of ductile iron pipe joints and hydraulic circulation experiments. The specific structure includes a square base 6, the two ends of the base 6 are fixed with a front retaining wall 1 and a rear retaining wall 7, and the front retaining wall 1 and the rear retaining wall 7 are connected by four pull rods 4, four The railings 4 are distributed on the four corners of the retaining wall, and the middle part of the front retaining wall 1 is provided with a push hydraulic cylinder 2, and the telescopic end of the push hydraulic cylinder 2 is equipped with a movable end block 3, and a pressure clamp 3 is installed at the middle part of the base 6. The lower mechanism 5 and the deflection hydraulic cylinder 8, there are two deflection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com