Cement mortar for inner liner of centrifugal ductile iron pipe

A centrifugal ductile iron and cement mortar technology, which is applied in the field of metallurgical production, can solve the problem of the peeling resistance of the inner lining and the decrease in the adhesion strength of the inner lining and the inner wall of the ductile iron pipe, the decrease in the strength of the inner lining of the centrifugal ductile iron pipe, and the cement mortar and ductile iron pipe. Workability and plasticity deterioration and other problems, to achieve the effect of improving strength and adhesion, improving competitiveness, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

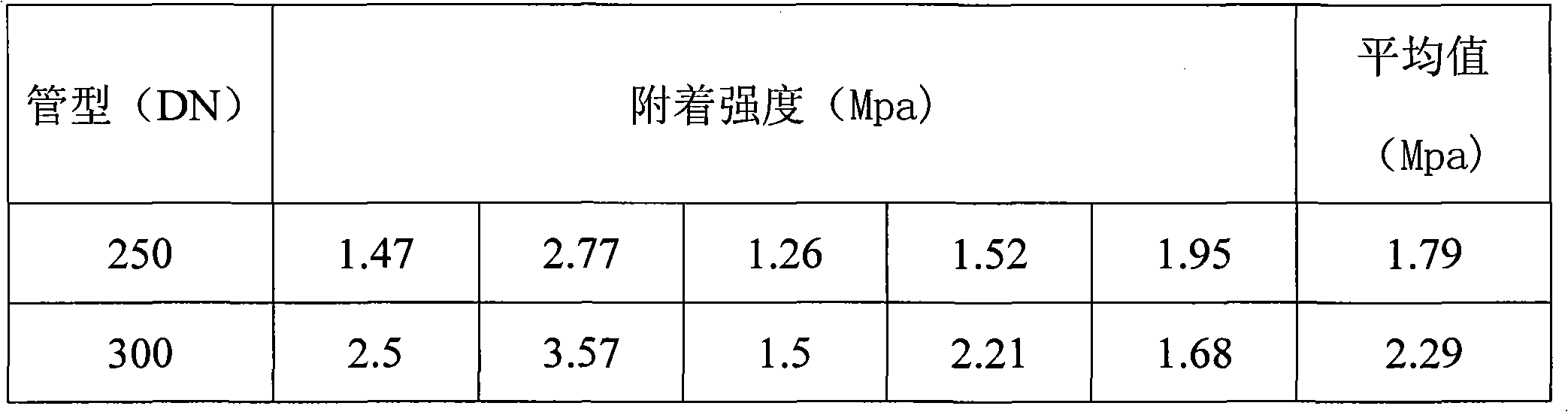

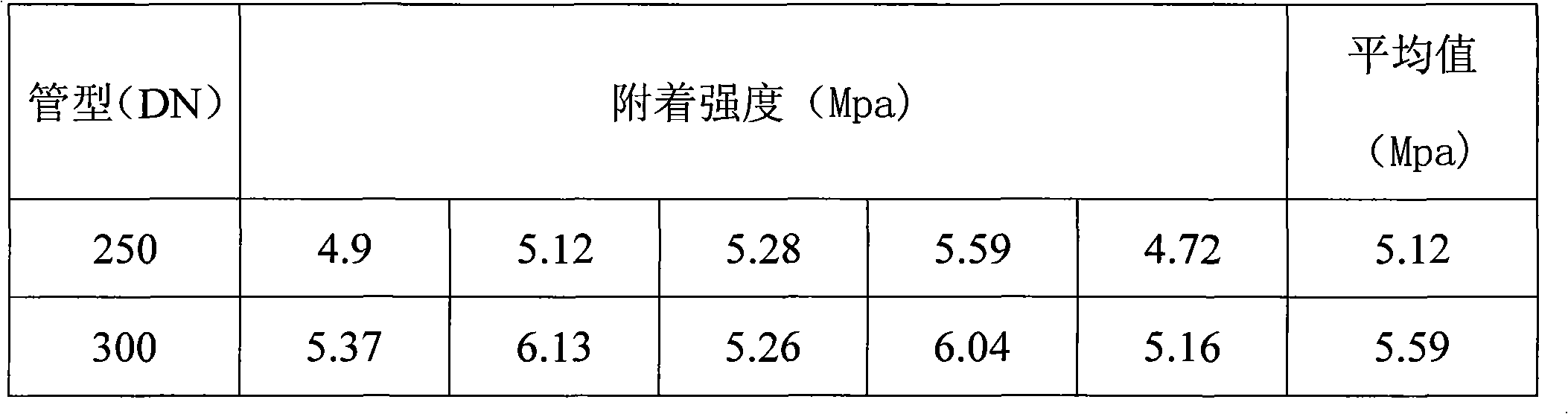

Examples

Embodiment 1

[0008] A cement mortar for the inner liner of centrifugal ductile iron pipes, the ratio of components by weight is: cement:sand:water:water reducer=1:1.0:0.25:0.008. The water reducer is a chlorine ion-free polycarboxylate high-performance water reducer produced by Hengsheng Concrete Admixture Co., Ltd. in Handan City, Hebei Province. Its appearance is light yellow liquid, with a pH value of 6-8 and a specific gravity of 1.06- 1.20g / cm 3 , Solid content 20%-40%. The water reducing agent is green and environment-friendly, has no corrosive effect on metals, does not require equipment modification during use, has a small amount of addition, is simple to operate, and has an obvious effect of improving the strength of the cement mortar lining layer. The cement mortar provided in this example is suitable for preparing the inner lining layer of a centrifugal ductile iron pipe with a nominal diameter of DN80.

Embodiment 2

[0010] The difference from Example 1 is that the cement mortar used for the inner liner of the centrifugal ductile iron pipe in this example has a ratio of parts by weight of each component: cement: sand: water: water reducer = 1: 1.5: 0.35:0.012. The cement mortar provided in this example is suitable for preparing the inner lining layer of a centrifugal ductile iron pipe with a nominal diameter of DN300.

Embodiment 3

[0012] A cement mortar for the inner liner of centrifugal ductile iron pipes, the ratio of components by weight is: cement:sand:water:water reducer=1:1.0:0.25:0.01. The water reducer is a sulfamate high-efficiency water reducer produced by Hunan Pioneer Building Materials Co., Ltd. The cement mortar provided in this example is suitable for preparing the inner lining layer of a centrifugal ductile iron pipe with a nominal diameter of DN80.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com