Centrifugal spheroidal cast iron pipe with plastic lining

A technology of centrifugal ductile iron and manufacturing method, applied in mechanical equipment, coating and other directions, can solve the problems of increased pipeline weight, easy growth of microorganisms, inconvenient construction and installation, etc., and achieves the effect of overall weight reduction, smooth inner wall, and convenient construction and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

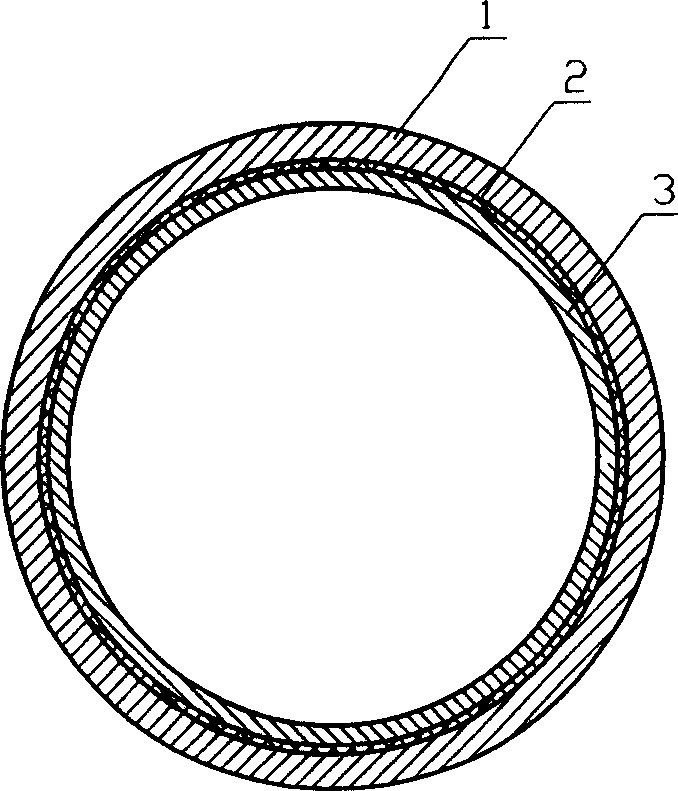

[0027] figure 1 Shown is the embodiment of a kind of plastic-lined centrifugal ductile iron pipe of the present invention, is provided with lining pipe 3 in centrifugal ductile iron pipe body 1, and this lining pipe 3 is polyethylene plastic pipe, in cast iron pipe body 1 Adhesive layer 2 is arranged between lining pipe 3 .

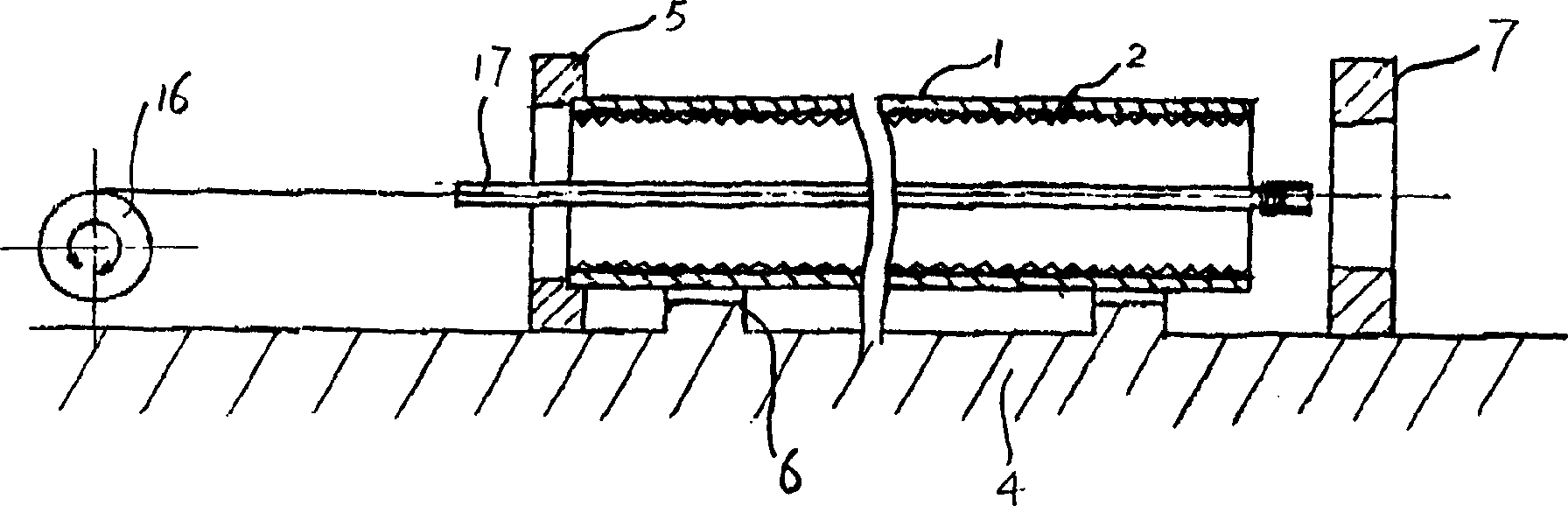

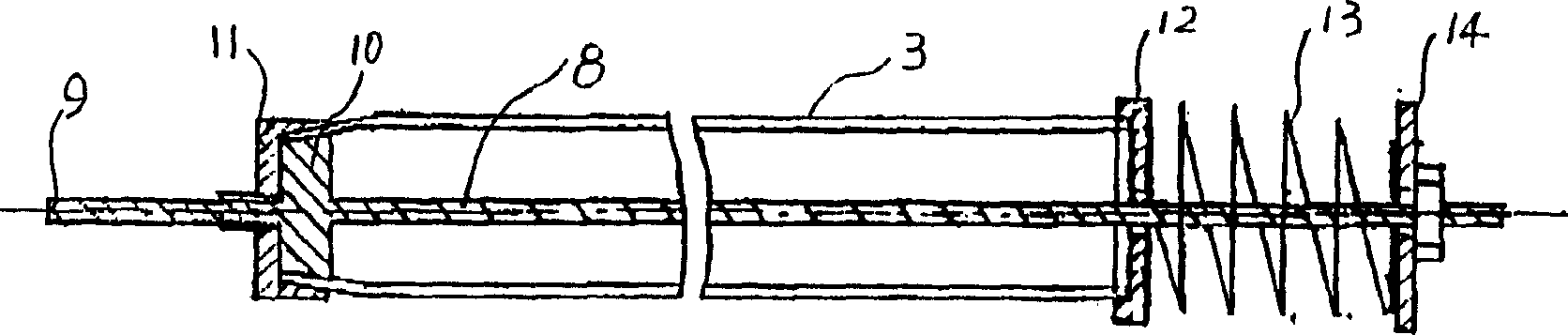

[0028] figure 2 , image 3 , Figure 4 Shown is the schematic diagram in the manufacturing process of above-mentioned plastic-lined centrifugal ductile iron pipe of the present invention, carries out according to the following steps:

[0029] a. Select a centrifugal nodular cast iron pipe 1 with an inner diameter of 106 mm, apply adhesive 2 on its inner wall, and then install the cast iron pipe body 1 on the frame 4 of a large-stroke broaching machine with a stretching machine, one end of the cast iron pipe body 1 It is fixed on the fixed baffle plate 5 of the frame 4; the pipe body is fixed by the supporting plate 6 on the frame 4, and the reducing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com