Cement lining device of centrifugal spherical graphite cast-iron pipe

A centrifugal ductile iron and cement technology, applied in ceramic molding machines, manufacturing tools, etc., can solve problems such as uneven rotation speed of driving rollers, waste pipes, blockage of hydraulic valves, etc., to improve product quality, production efficiency, and rotational speed. Uniform and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

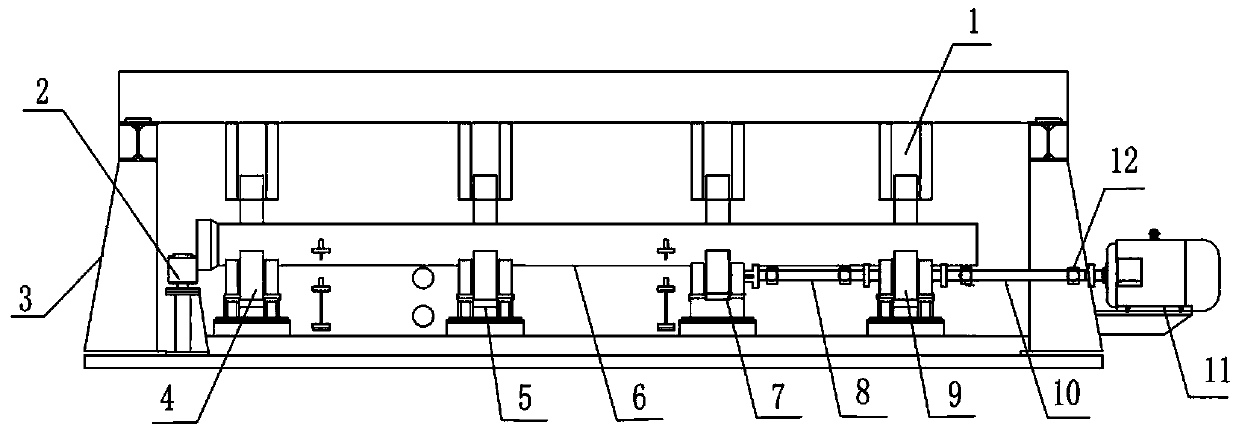

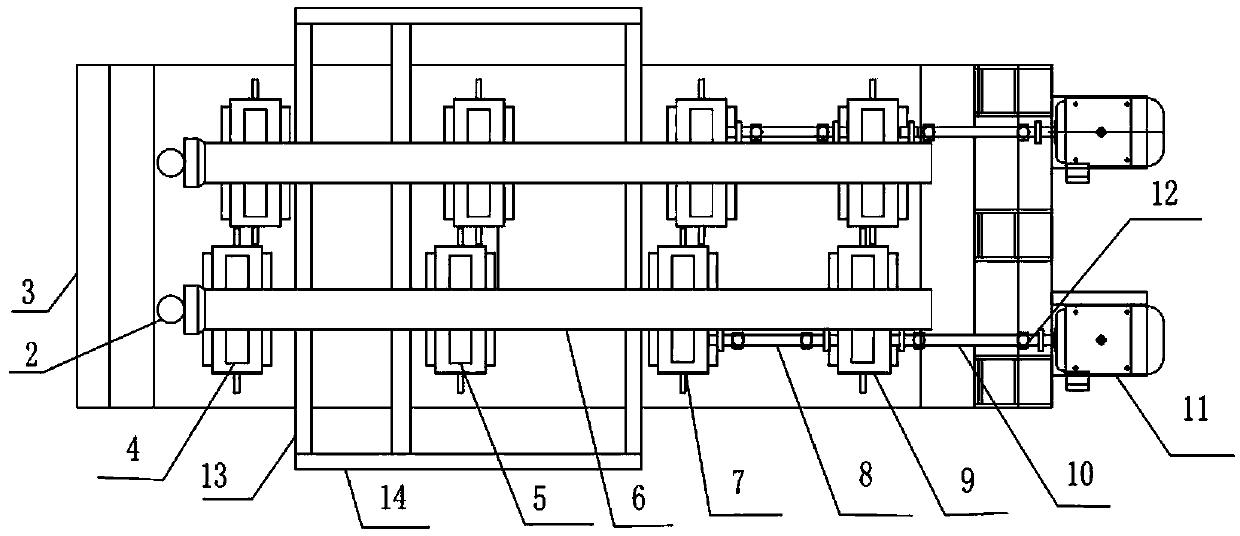

[0016] Depend on Figure 1 to Figure 3 It can be seen that the present invention mainly includes a frame 3, a pressure roller group 1, a first driving roller group 7, a second driving roller group 9, a first driven roller group 4, a second driven wheel roller group 5 and a block Wheel 2, the first driving idler set 7, the second driving idler set 9, the first driven idler set 4, and the second driven idler set 5 are all installed on the frame 3, and on the Above the corresponding positions of the first driving idler set 7, the second driving idler set 9, the first driven idler set 4, and the second driven idler idler set 5, a pinch roller set 1 is installed, and the pinch roller set 1 is fixed on the frame 3, and each pressure roller group 1 is controlled by a hydraulic cylinder to lift up and down, and the retaining wheel 2 is installed on the frame 3 on the side of the first driven supporting roller group 4, and the axis of the retaining wheel 2 and the nodular cast iron Th...

Embodiment 2

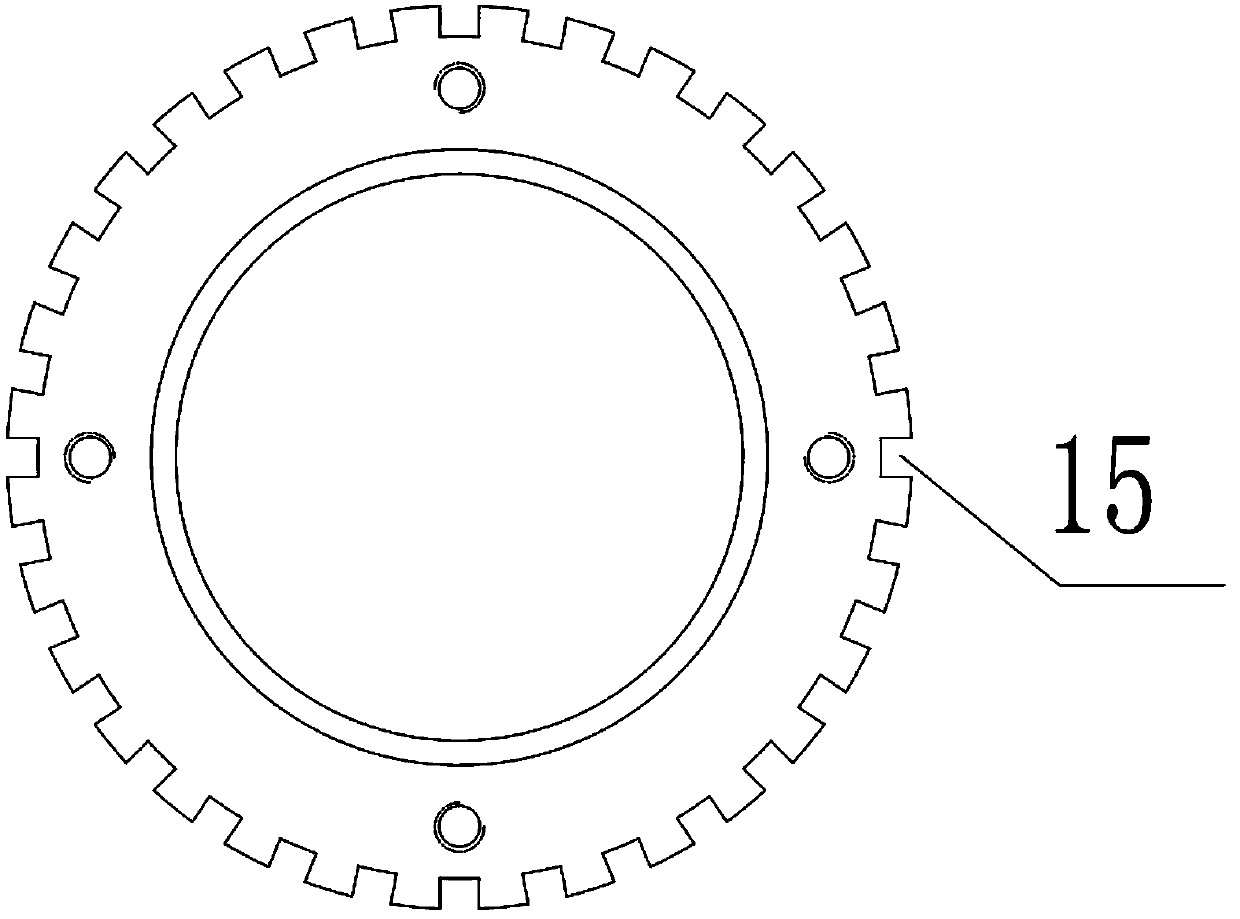

[0024] Depend on Figure 4 It can be seen that in the present invention, the section of the elongated groove 15 in the retaining wheel 2 is trapezoidal, and the effect described in the first embodiment can also be achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com