Long barrel internal and external wall spiral type helical swinging built up welding method and equipment

A wall-wound, spiral swing technology, which is applied in the field of long cylinder inner and outer wall-wound spiral swing surfacing welding and equipment, to achieve the effect of improving thermal fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

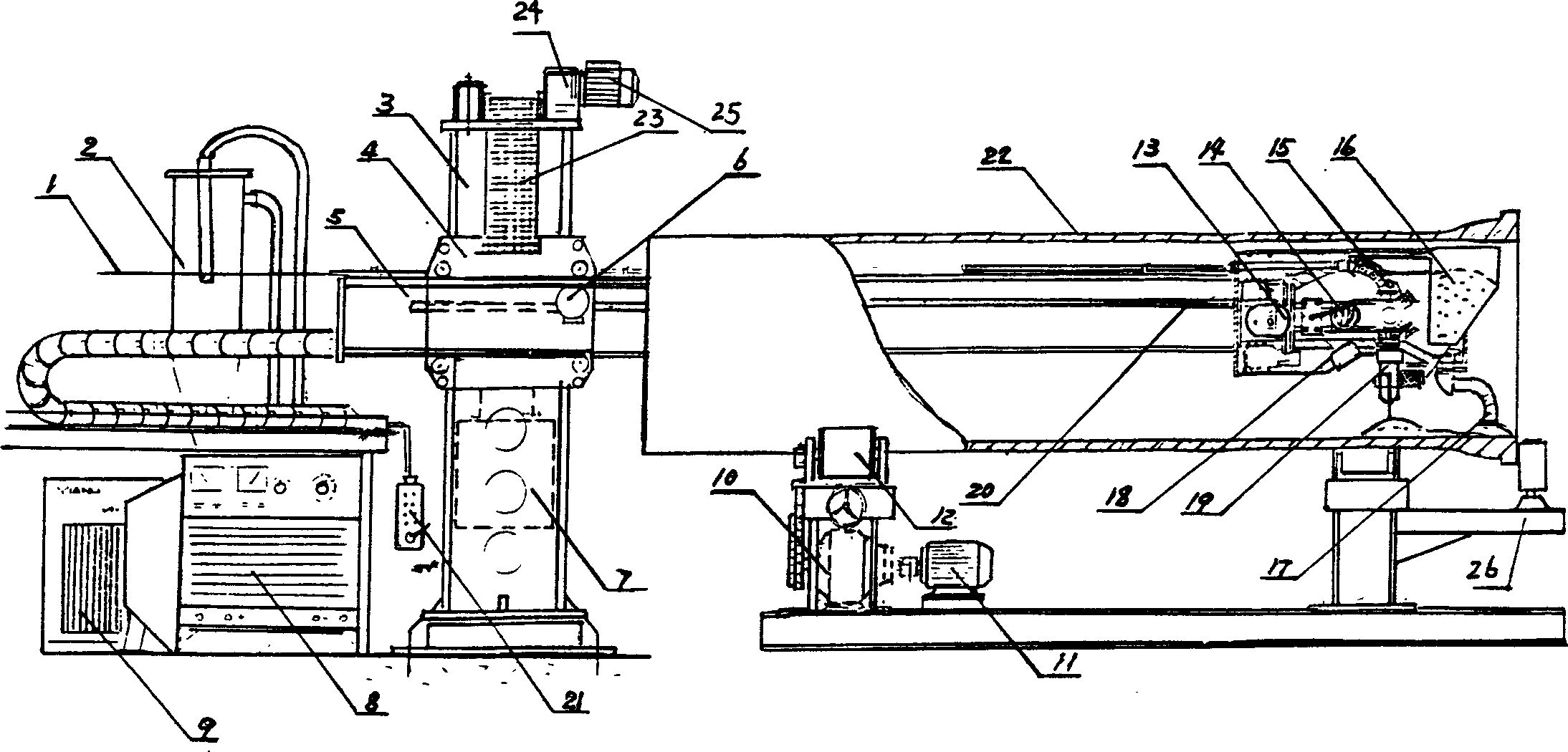

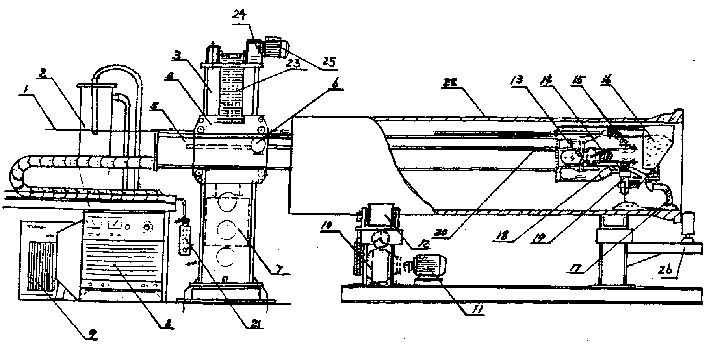

[0010] In order to meet the requirements of the above-mentioned surfacing method, the present invention must be equipped with special equipment for automatic surfacing welding with inner and outer walls of the long cylinder as a guarantee, so as to realize the special equipment structure of winding spiral oscillating surfacing welding for the inner and outer walls of the long cylinder. See figure 1 , The special equipment for automatic surfacing welding with inner and outer walls of the long cylinder is composed of: welding wire 1 (single wire or double wire), flux automatic conveying and recycling device 2, surfacing machine lifting column 3, surfacing machine beam sliding seat 4, surfacing machine beam 5. Beam stepper motor 6, beam counterweight 7, surfacing welding machine power supply 8, welding machine water cooling system 9, cycloid pin-tooth planetary reducer 10, switch magnetic group speed regulating motor 11, roller bracket 12, welding head Electric cross carriage 13,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com