Process for coating polyurethane on inner and outer surface of nodular graphite cast iron pipe

A ductile iron pipe, inner and outer surface technology, applied in the device for coating liquid on the surface, pretreatment surface, coating and other directions, can solve the problems of poor wear resistance, poor salt spray resistance, poor acid and alkali resistance, etc. Wide temperature range, no pollution in ecological environment, outstanding effect of medium resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

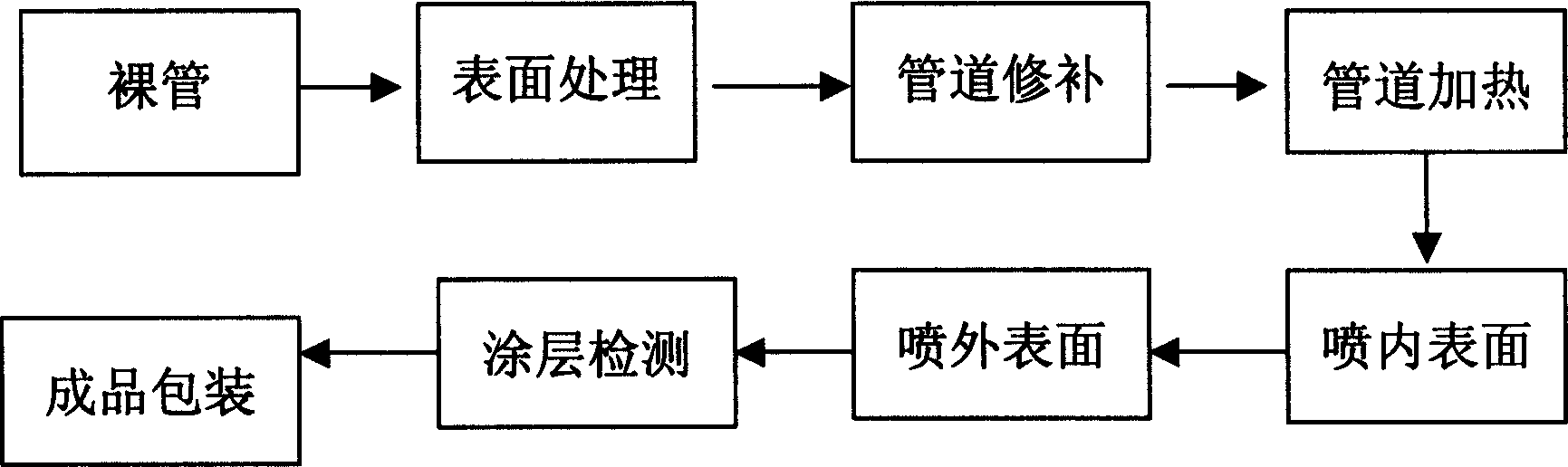

[0007] The process steps of the present invention are successively: 1, surface treatment. (1) The outer surface is shot blasted. The outer surface of the pipe must be degreased and derusted to Sa2.5 level; (2) The inner surface is polished. There are many casting defects such as protrusions on the inner surface of the pipe, which must be smoothed before spraying. 2. Repair the surface of the pipeline. For larger defects on the surface of the pipeline, such as pits with a diameter greater than 2mm, the pits need to be filled with putty. 3. Pipeline heating, the best heating temperature is 20-80°C. 4. Spraying the inner surface. When the temperature of the pipeline reaches the requirement, start the high-pressure airless spraying machine, and the spraying trolley drives the spray gun to spray at a constant speed. The spraying process parameters are shown in Table 1. 5. Spraying on the outer surface. When the temperature of the pipeline reaches the requirement, start the high-pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com