Treating technology for ductile iron pipes after annealing

A nodular cast iron pipe and processing technology, which is applied in the field of pipe manufacturing, can solve the problems of long time-consuming process, low efficiency, high labor intensity, etc., and achieve the effect of improving quality control level, simple and accurate process, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

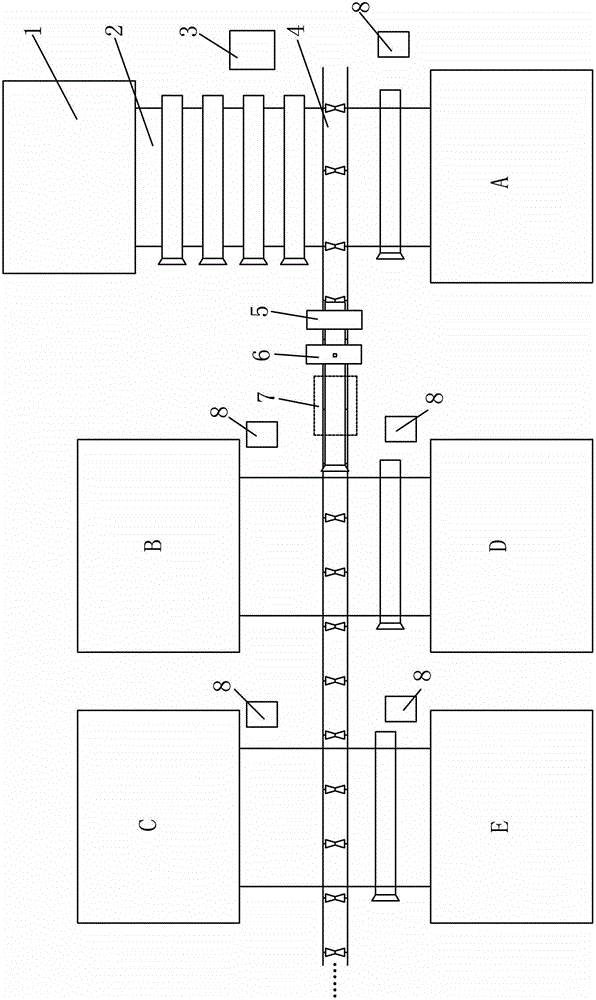

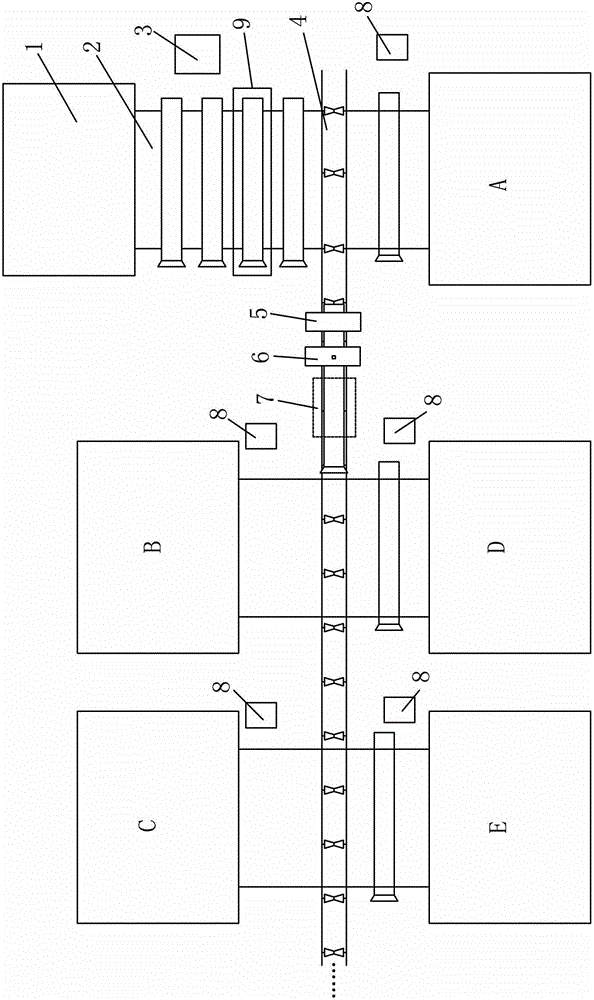

[0014] Such as figure 1 In the shown embodiment 1, before the ductile iron pipe enters the annealing furnace 1, a production line and a mapping table of the relative position of each online ductile iron pipe on the production line have been preset in the computer control system, and each pipe type is recorded in the mapping table The standard values of the appearance, pipe diameter, ovality, and wall thickness of the ductile iron pipes, and number the ductile iron pipes according to the order in which the ductile iron pipes leave the annealing furnace 1. The position is changed, and the treatment process after the ductile iron pipe leaves the annealing furnace 1 includes the following steps: (1) The ductile iron pipe enters the first transportation line 2 after being annealed in the annealing furnace 1, and a plurality of ductile iron pipes are sequentially placed on the first transportation line 2 Arranged, and the axial direction of the ductile iron pipe is perpendicular t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com