Device capable of cleaning outer wall of nodular cast iron pipe or pipe mold

A technology of ductile iron pipes and pipe molds, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc. It can solve the problems of high consumption of wearing parts, different grinding depths, and difficult cleaning, so as to prevent wear and tear , Improve cleaning quality, improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

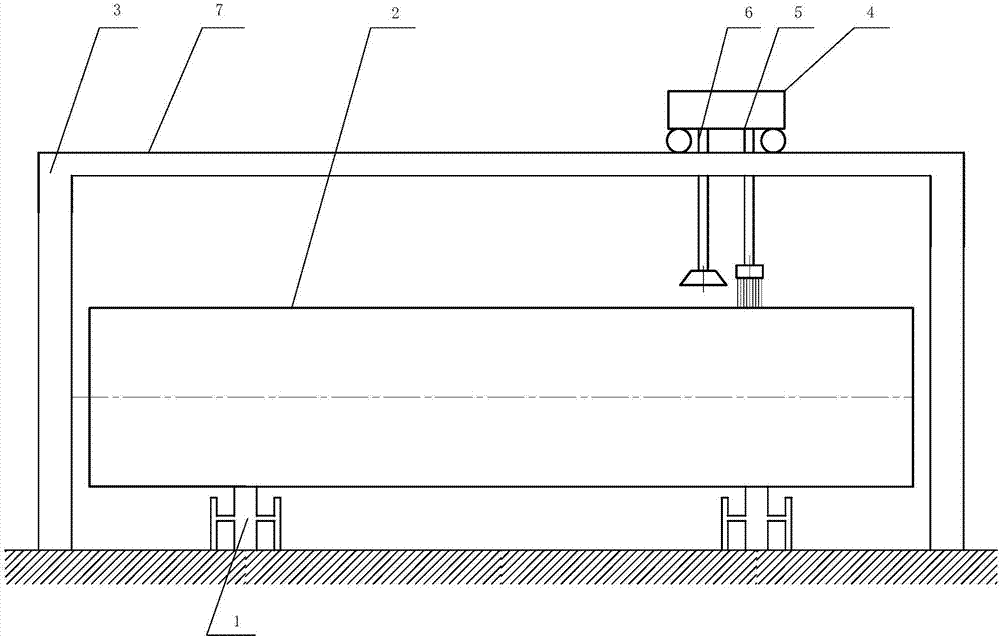

[0018] Such as figure 1 As shown, the device for cleaning the ductile iron pipe or pipe mold outer wall of the present invention includes: at least two support wheels 1, support 3, track 7, trolley 4, dust suction cover 6 and laser cleaning machine 5, on the support 3 Track 7 is equipped with above, and at least two support rollers 1 are installed directly below track 7, and support roller 1 is two, and they are placed in the position directly below track 7 and parallel with track 7. The ductile iron pipe or pipe mold 2 is placed on at least two support rollers 1, one or both of the at least two support rollers 1 are driven to rotate by the motor, and the support roller 1 drives the ductile iron pipe or pipe mold 2 mounted on it Rotate, a trolley 4 and a vacuum cover 6 are installed on the track 7, the trolley 4 walks on the track 7, the trolley 4 is a trolley with a driving device, a laser cleaning machine 5 is installed on the trolley 4, and the laser cleaning machine 5 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com