Self-anchoring port fixedly-connecting structure

An interface and fixed welding technology, which is applied in the direction of flange connection, sleeve/socket connection, pipe/pipe joint/pipe fitting, etc., can solve the problem that the self-anchor interface cannot meet the requirements, so as to prevent mutual disengagement and reduce construction costs , The effect of bolt strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

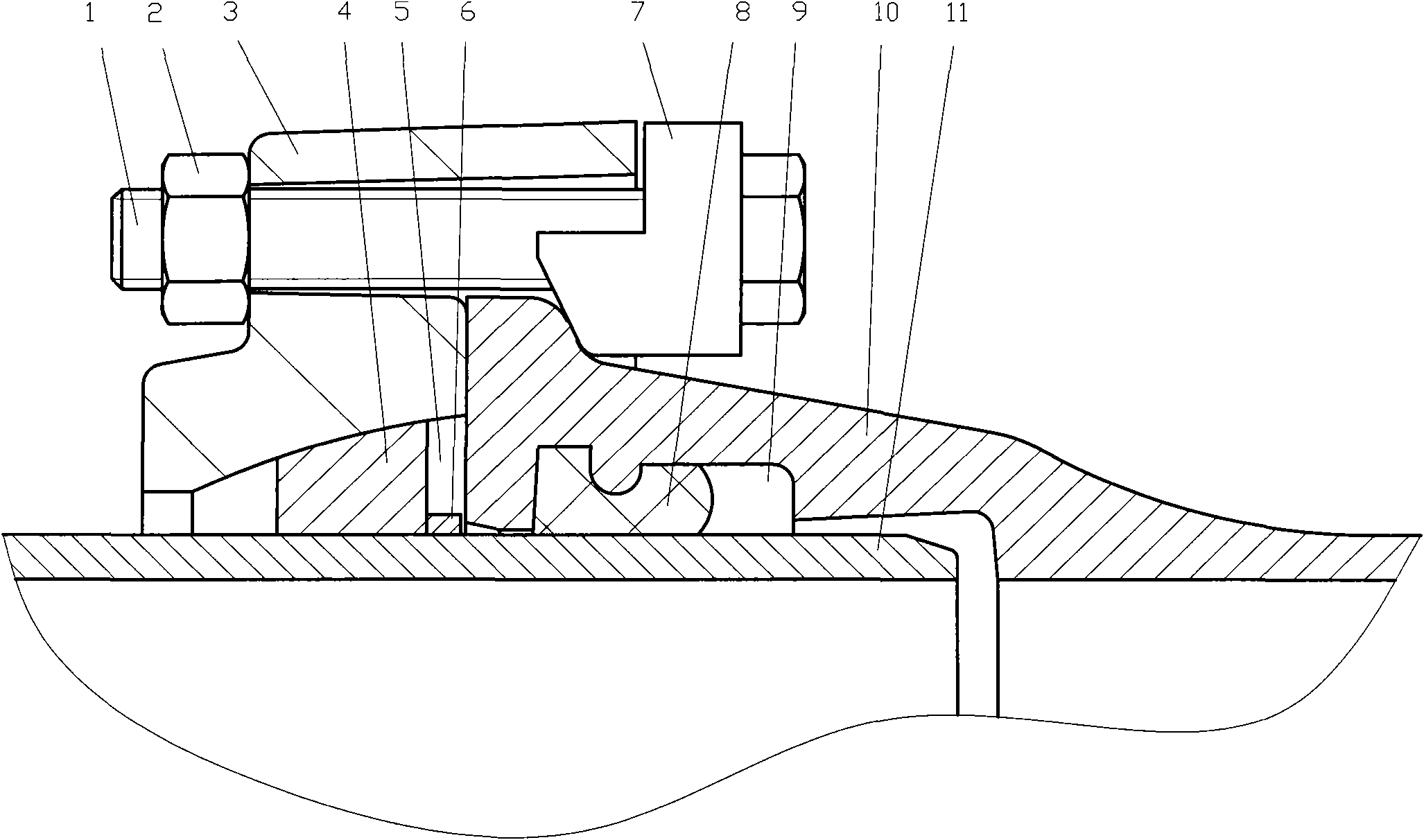

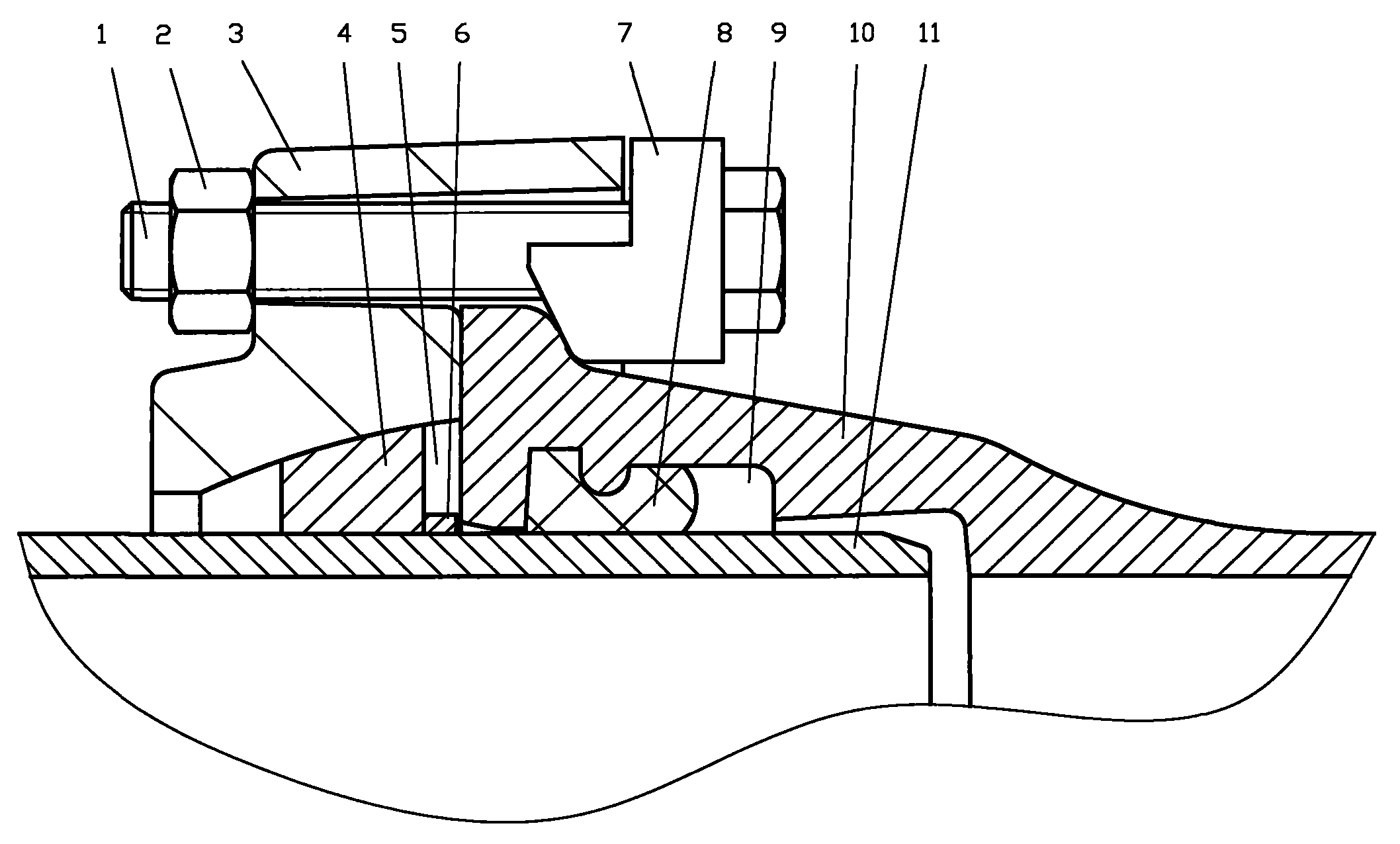

[0008] As shown in the drawings, the socket 11 of the ductile iron pipe is inserted into the socket 10 of the ductile iron pipe. There is a sealing groove 9 on the inner wall of the socket 10, and a sealing ring 8 is embedded in the sealing groove 9. The left end of the socket 10 There is a pressure flange 3 on the top of the surface, and the pressure flange 3 is fixed to the socket 10 through the bolt 1, the nut 2 and the pressure block 7. The pressure flange 3 has a tapered inner hole 5, and the socket 11 in the tapered inner hole 5 is covered with a stopper. Ring 4, fixed welding ring 6 on the socket 11 of retaining ring 4 right-hand sides.

[0009] The pressure flange 3 is an integral circular ring.

[0010] When the interface is affected by the internal water pressure, an axial force is generated, and the socket 11 of the ductile iron pipe will be pulled out from the socket 10. The interaction is transmitted to the pressing block 3 and the bolt 1, and because the bolt 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com