Interface structure of ductileiron pipe

A technology of ductile iron pipe and interface structure, which is applied in the direction of pipe/pipe joint/pipe fitting, sleeve/socket connection, passing components, etc. It can solve the problems of unreliable structure, complex structure, and damage to cast pipe by anchor block, and achieve The effect of simple structure and firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

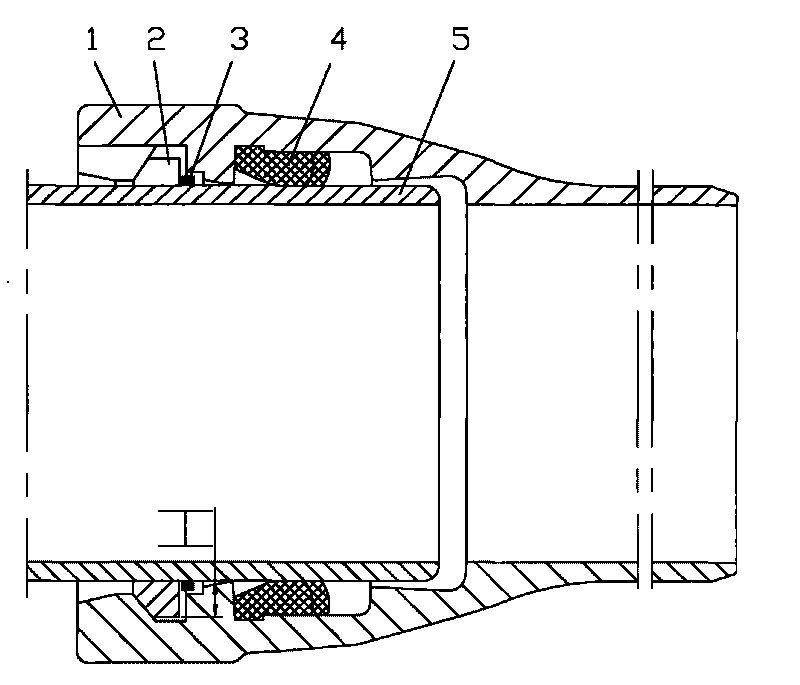

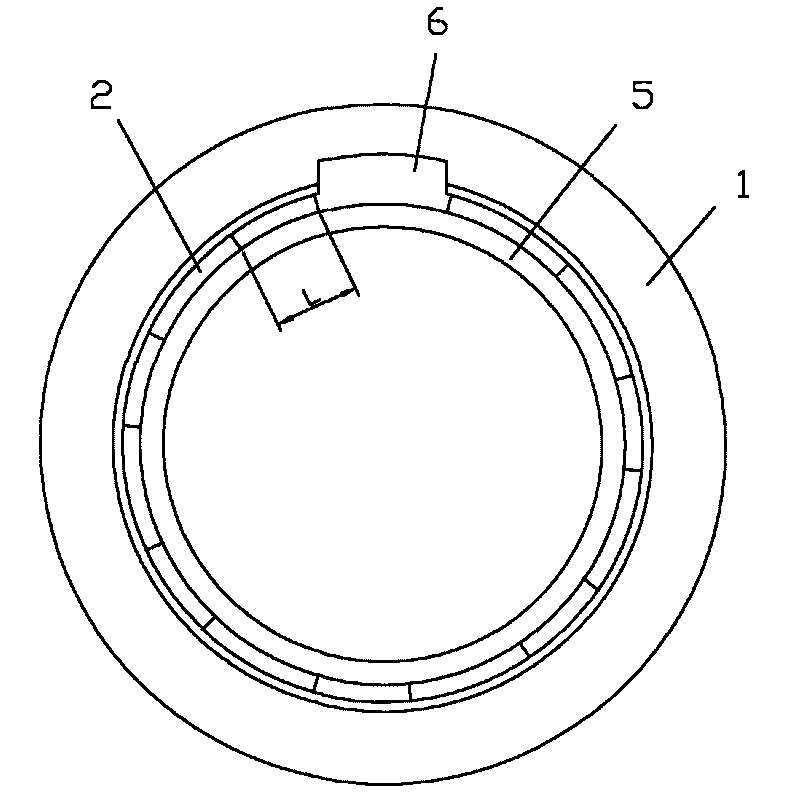

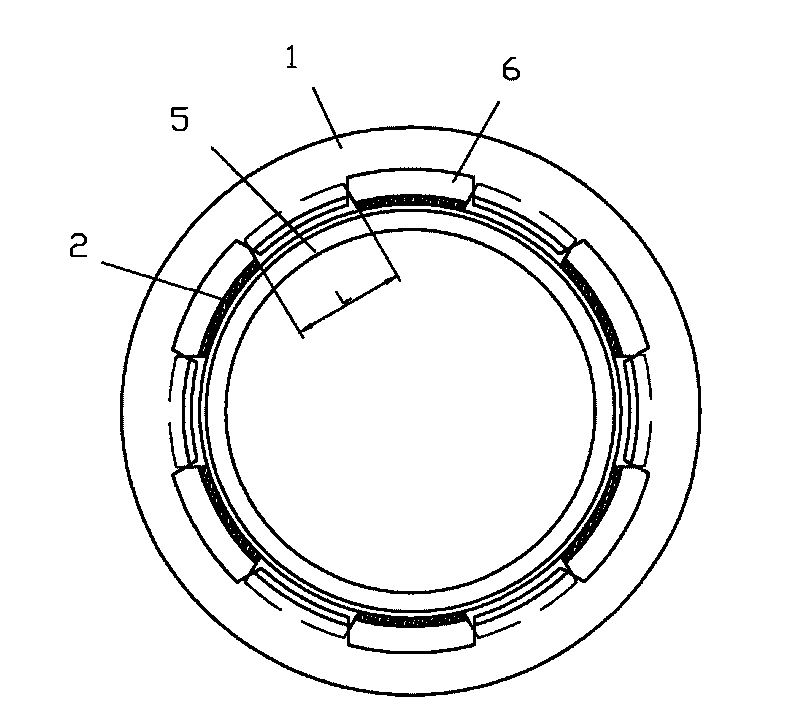

[0016] Such as figure 1 As shown, the inner cylindrical surface of the socket 1 of the ductile iron pipe has a retaining ring installation groove and a sealing ring installation groove, and a sealing ring 4 is embedded in the sealing ring installation groove. There is an anchor ring 3 on the outer cylindrical surface of the socket 5, and the anchor ring 3 is between the mounting groove of the retaining ring and the sealing ring, and is close to the mounting groove of the retaining ring. It communicates with the retaining ring installation groove. A retaining ring 2 is embedded in the retaining ring installation groove from the retaining ring mounting hole 6, the right end face of the retaining ring 2 is close to the anchor ring 3, and the left end face is close to the left annulus of the retaining ring mounting groove.

[0017] The retaining ring installation groove and the sealing ring installation groove are casting grooves, that is, they are formed by one-time casting on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com