Encased concrete nodular cast iron pipe

A technology of nodular cast iron pipes and outsourcing concrete, which is applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc. It can solve the problems of inconvenient jacking, large axial force, and no trench excavation is allowed, and shorten the construction cycle, prolong service life and reduce engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

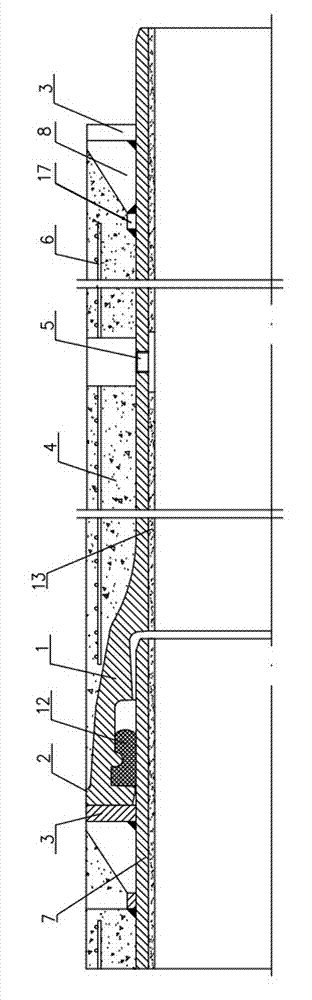

Embodiment 1

[0020] Embodiment 1: The present invention discloses a concrete ductile iron pipe, which includes a socket-type ductile iron pipe body with sockets 1 and sockets 7 at both ends; the key improvement is that the outer wall of the socket-type ductile iron pipe body Covered with a concrete layer 4 with the same overall length and diameter, the concrete layer 4 is sandwiched with a cylindrical steel mesh 6, the outer end of the socket 7 is provided with a connecting flange group, and the outer end of the socket 1 is An annular boss 2 is provided, and the outer diameter of the annular boss 2 is the same as that of the concrete layer 4 . In the specific construction process, put the socket-type ductile iron pipe body and the cylindrical steel mesh into the pre-processed mold, then pour concrete in the mold, and use the concrete layer to adjust its outer diameter to be consistent, which is convenient for jacking. For construction, the function of the annular boss is to ensure the mini...

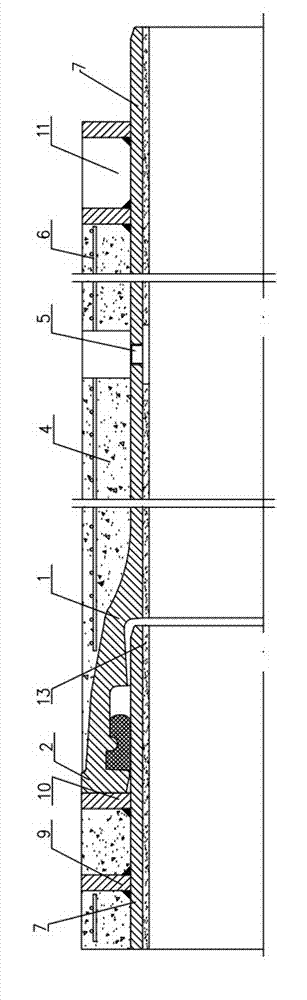

Embodiment 2

[0025] Embodiment 2: The difference between this embodiment and Embodiment 1 lies in the structure of the flange group. The flange group in this embodiment includes a third flange 10 and a third flange 10 arranged inwardly along the axis from the outer end of the socket 7. Between the second flange 9, the second flange 9 and the third flange 10, at least two second ribs 11 are evenly arranged radially around the axis of the socket-type ductile iron pipe. An axial rib is arranged between the second flange 9 and the third flange 10 to strengthen the bearing end.

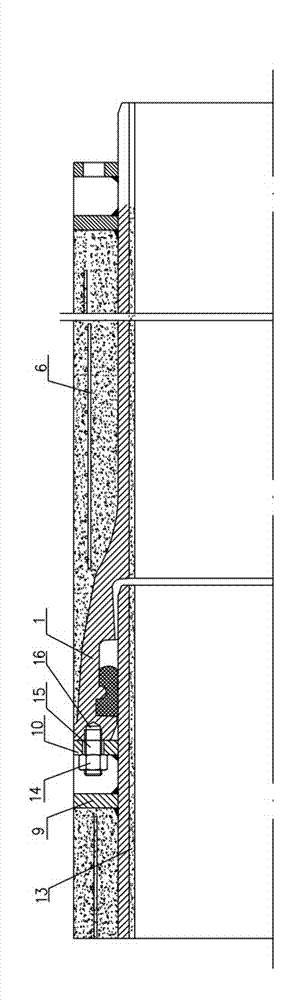

Embodiment 3

[0026] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the third flange 10 is provided with at least four through holes uniformly arranged radially around its axis, and the socket-type ductile iron pipe The end of the socket 1 is provided with threaded holes 16 with the same number and the same position as the through holes, and the flanges on the socket end of the front pipe and the socket end of the rear pipe are passed through the double-headed Bolt connection enhances the rigidity of the connection between the two pipes. Specifically, it is realized in this way. First, insert the socket of the rear pipe into the socket of the front pipe before jacking the rear pipe, and pass the stud bolt 15 through the socket provided on the third flange. Through hole is screwed into threaded hole 16, and is tightened with nut 14, then carries out jacking.

[0027] To sum up, the key of the present invention is to attach a concrete layer on the outer wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com