Cast iron pipe outer wall grinding device

A cast iron pipe and grinder technology, which is used in grinding/polishing safety devices, grinding machines, grinding workpiece supports, etc., can solve the problems of large residual dust on the surface of the pipe wall, inability to be absorbed by fans, and dangerous dust pollution. To achieve good grinding effect, good vibration effect, to ensure the overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

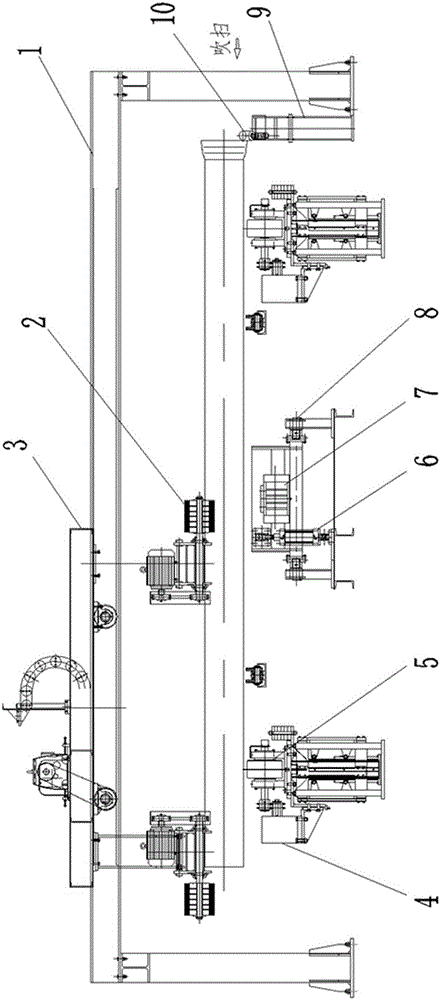

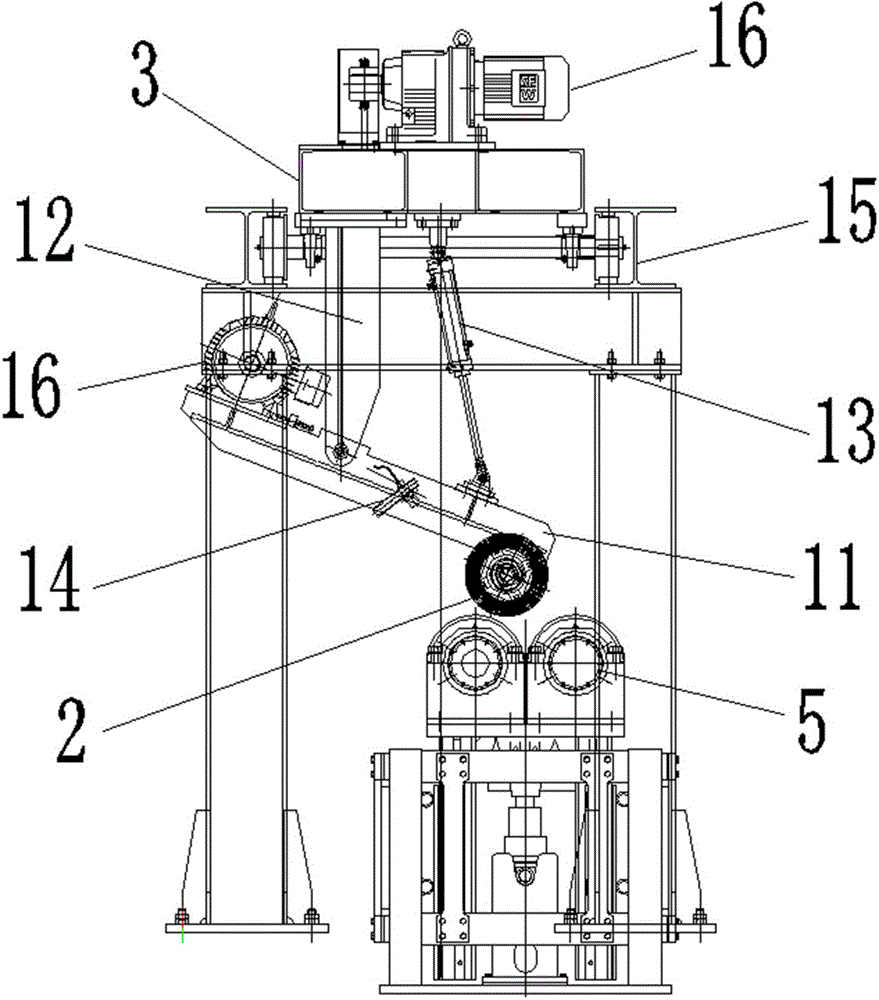

[0020] In order to solve the technical problems that the grinding and cleaning of the cast iron pipe wall and the pipe body after grinding are labor-intensive, and the existing grinding equipment has poor grinding and cleaning effects and low efficiency, the invention discloses a grinding device for the outer wall of a cast iron pipe. Type grinder and the technical means of installing vibrating device and blowing device can effectively grind and clean the wall of cast iron pipe with high efficiency. In order to describe the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

[0021] A grinding device for the outer wall of a cast iron pipe, comprising a rectangular parallelepiped support frame 1, 5 groups of rotating rollers are arranged at the inner bottom of the frame, including two pairs of rotating rollers 5 at the front and rear, and the roller surfaces of each pair of rotating rollers 5 are u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com