Nodular cast iron foundation pile pipe and a method for preparing same

a technology of nodular cast iron and pile pipe, which is applied in the direction of furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of long construction time and high labor intensity, and achieve the effects of high strength, effective improvement of mechanical properties of cast iron, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

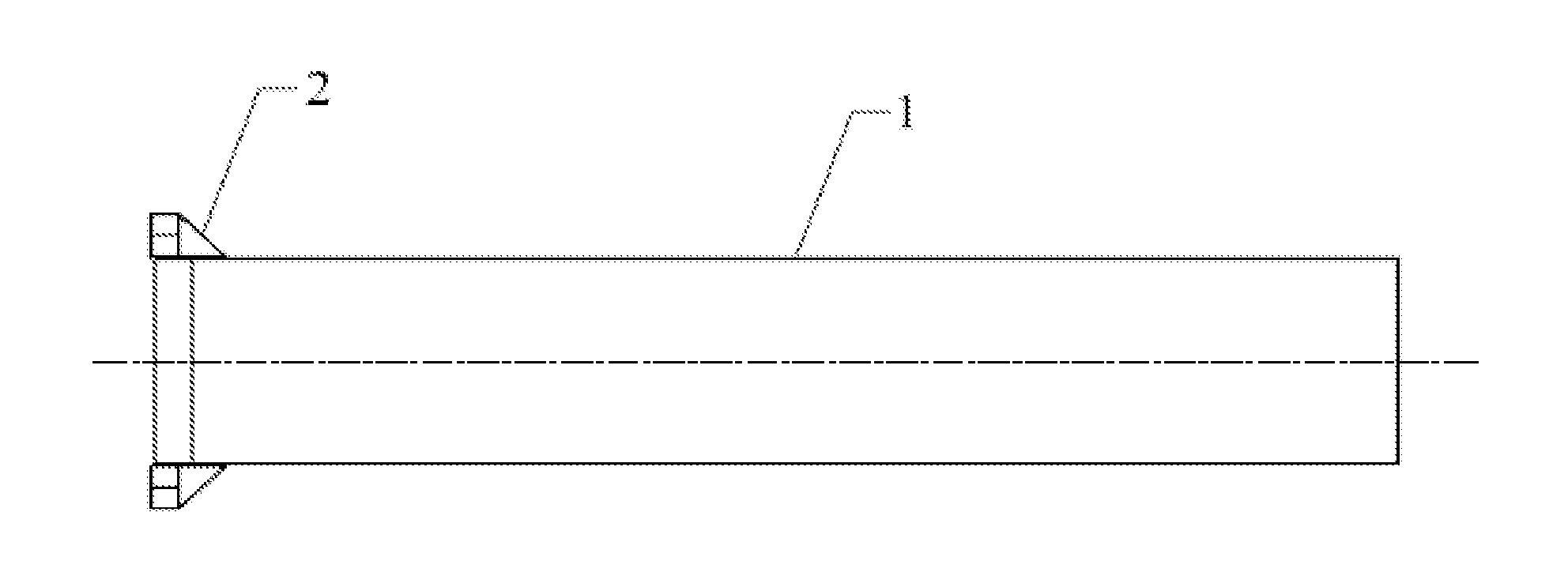

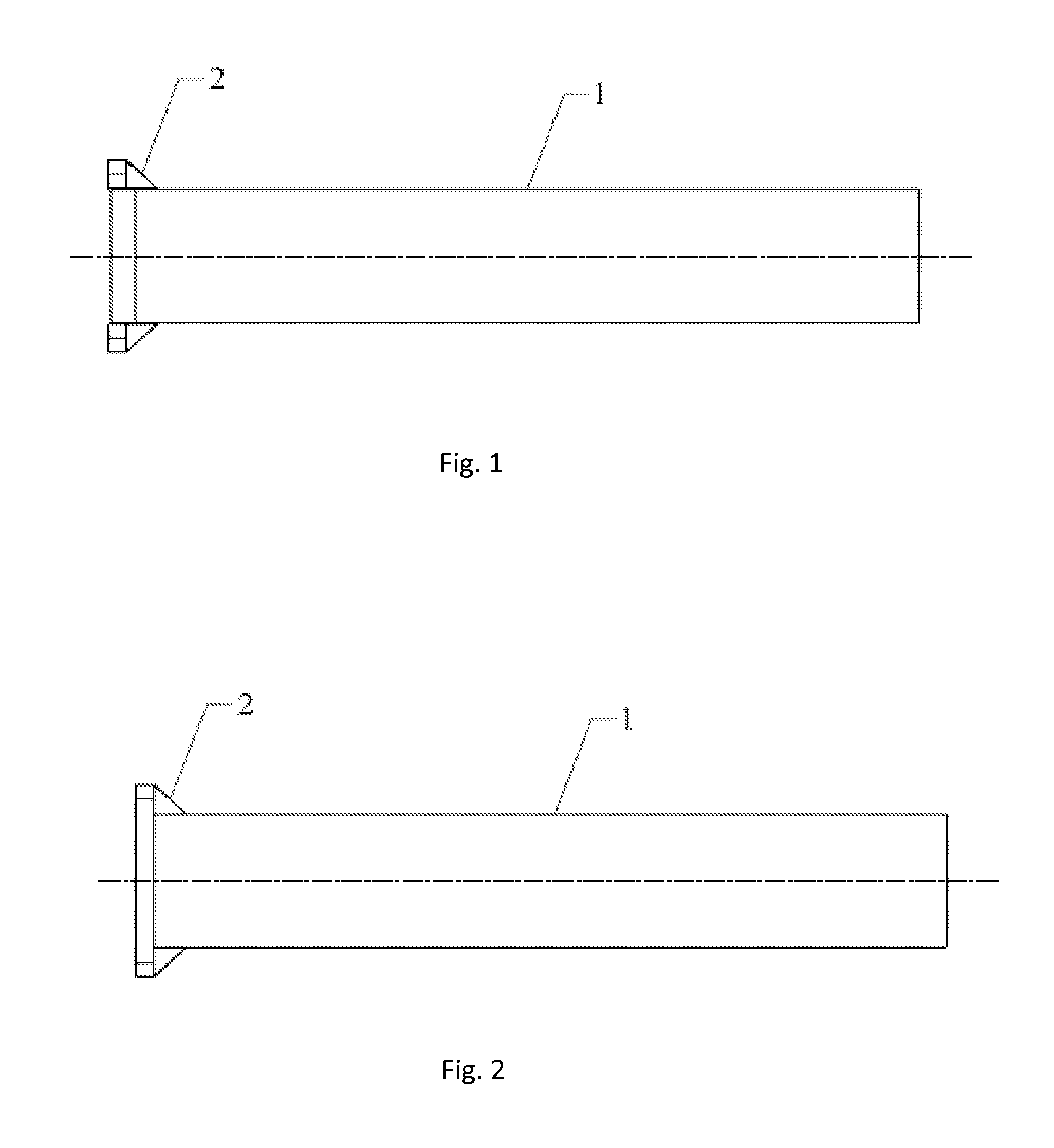

Image

Examples

Embodiment Construction

[0032]A nodular cast iron foundation pile pipe and a technology for preparing same, the technology comprises following steps:

[0033](1) preparation before pipe casting: including molten iron preparation, spheroidization and coating spraying on an inner wall of a pipe mold,

[0034]wherein the molten iron preparation includes heating the molten iron with medium frequency furnace to a temperature of 1460° C.-1500° C., and mass fractions of main chemical compositions in the molten iron are:

[0035]C: 2.9-3.2%, Si: 1.4-1.6%, Mn≦0.5%, Ti≦0.04%, P≦0.06%, S≦0.020%; the spheroidization includes using any of pour-over method, wire feeding spheroidizing method or pure magnesium spheroidizing method to spherize the molten iron, mass fractions of main chemical compositions in the spheroidized molten iron are:

[0036]C: 3.0-3.3%, Si: 1.9-2.4%, Mn≦0.5%, P≦0.06%, S≦0.02%, Mg: 0.03-0.06%, Ti≦0.04%; and the spheroidized molten iron is set aside for later use after slag removal;

[0037]the pipe mold is a die u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com