Selectivity improvement in oxygen delignification and bleaching of lignocellulose pulp using singlet oxygen

a technology of lignocellulose and oxygen delignification, which is applied in the field of process for delignification and bleaching of lignocellulose pulp and improving selectivity, can solve the problems of peeling, reducing pulp strength, and reducing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

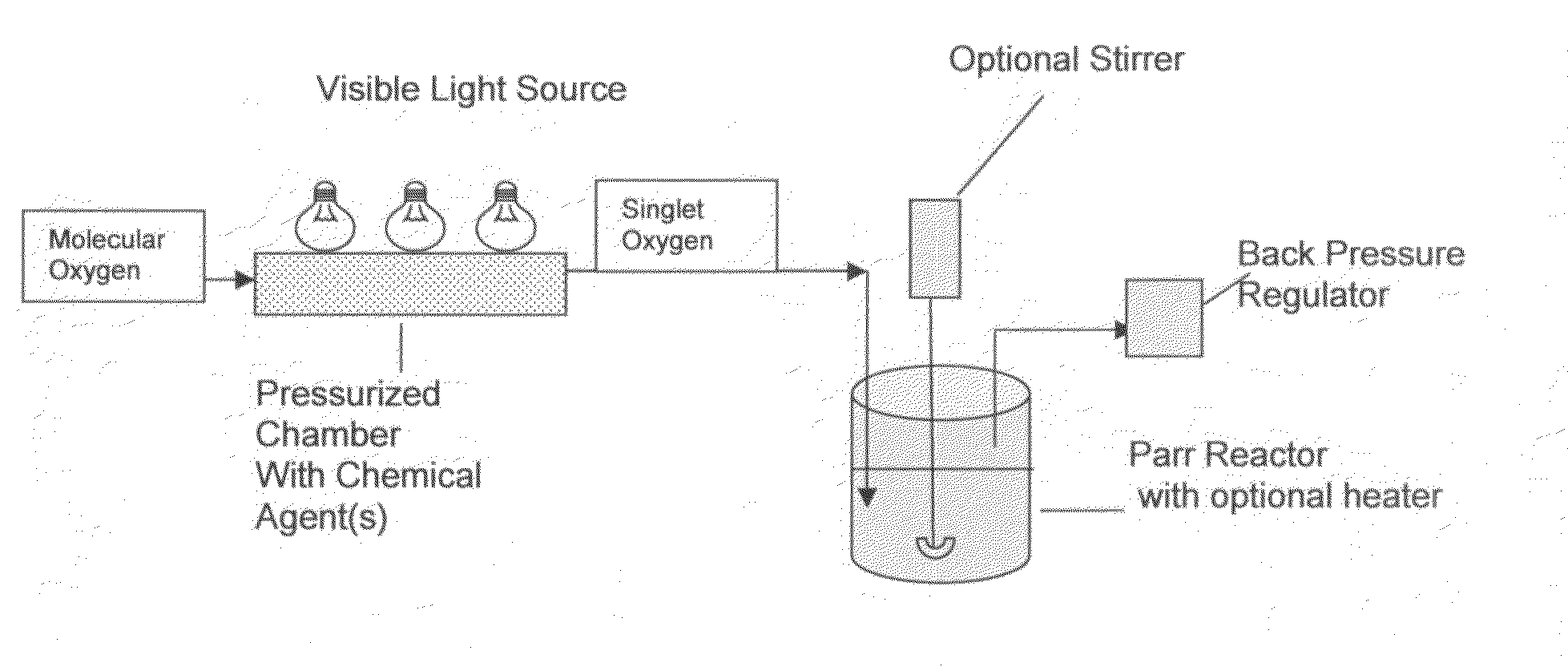

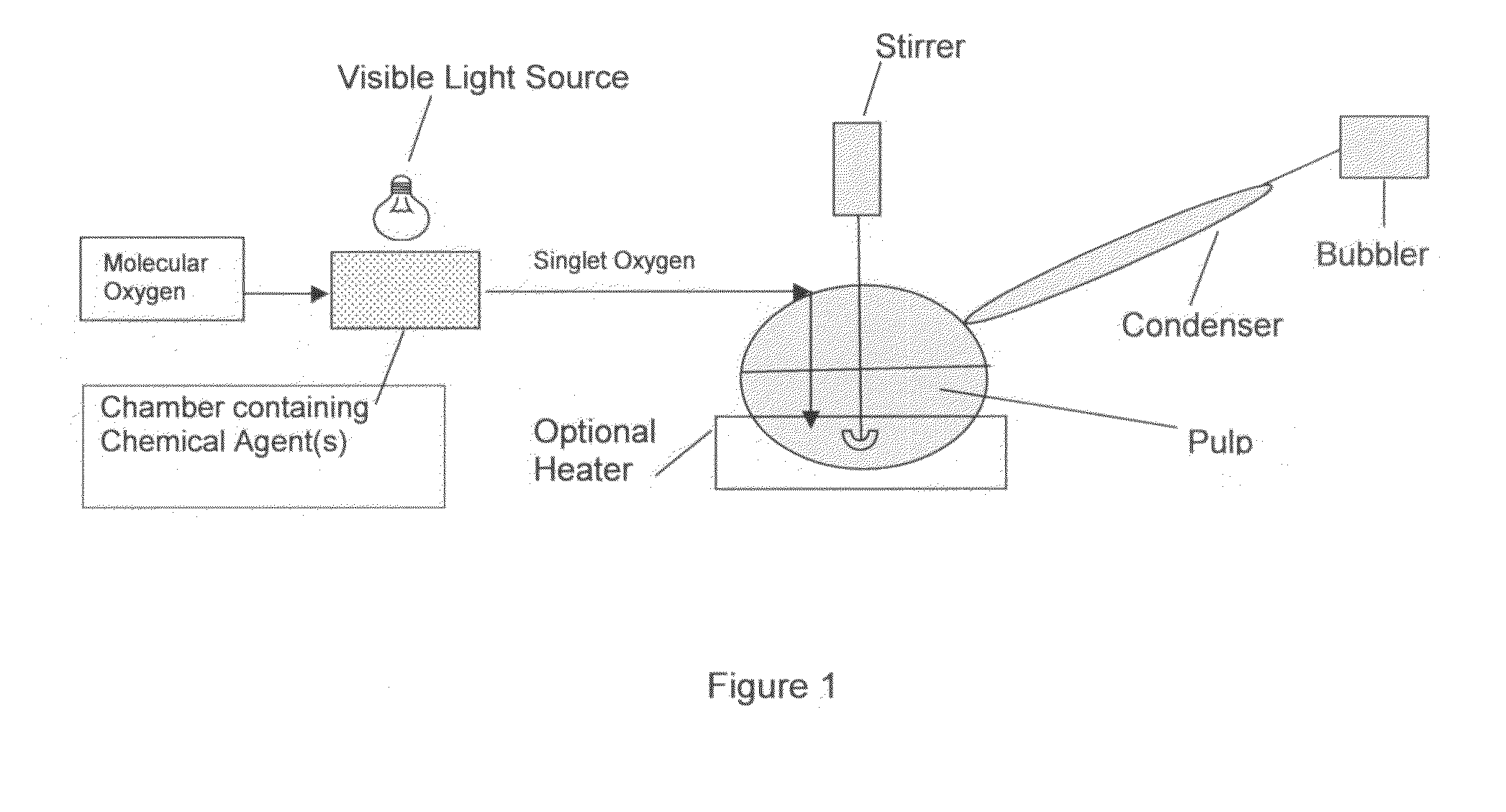

[0080]The equipment included a three-necked round bottom flask equipped with a mechanical stirrer, a condenser with gas bubbler, gas inlet with a U-tube (or reduced ends tube) filled with methylene blue prior to entering the round bottom flask, and a 500 W portable halogen worklight source (Stanley Tools, Manufacturer No. XG-1009) as shown in FIG. 1. The flask was charged with 110.82 g deionized water, 3.0 g sodium hydroxide (NaOH), 0.18 g magnesium sulfate (MgSO4) and 6.0 g softwood pulp with a starting Kappa number of 54.4. Softwood pulp was added after the sodium hydroxide and magnesium sulfate completely dissolved. The reaction flask was heated to reflux (100° C.) for four hours. Molecular oxygen flows from the oxygen tank and is treated in a separate stream in a chamber via a combination of visible light and a chemical agent, which is then applied to the pulp mixture. The flow rate of the molecular oxygen was between 110 to 140 mL / min and more typically 125 mL / min as measured b...

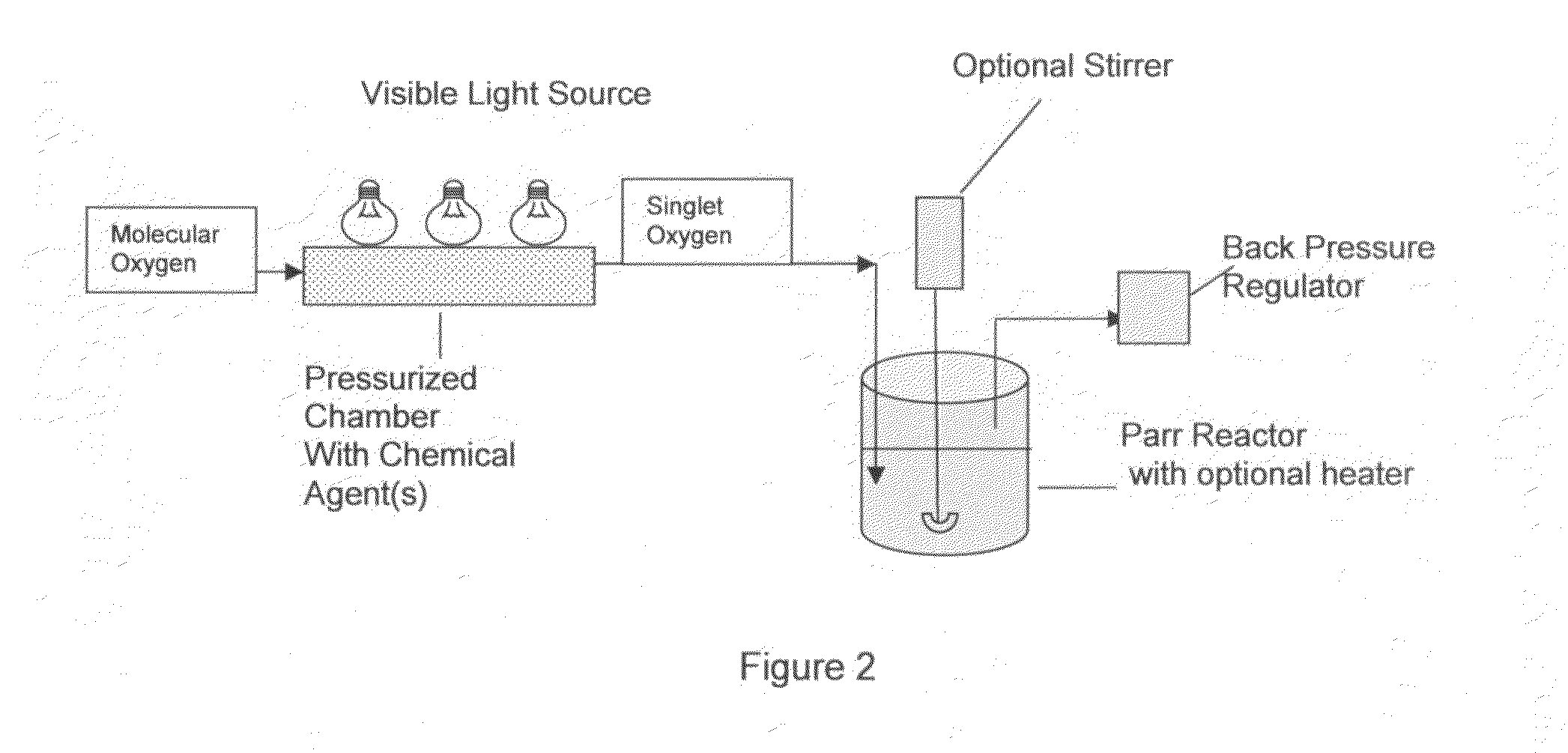

example 2

[0085]The Parr reactor was charged with 180 g deionized water, 19.31 g softwood pulp (18.0 g oven dried pulp), and 0.0072 g NaOH. Softwood pulp was added after the sodium hydroxide and magnesium sulfate completely dissolved. The reaction flask was heated to 100° C. at 275 kPa for 90 minutes. The one-piece pressure reactor manifold (Ace Glass, Vineland, N.J.) was packed with glass wool, Drierite® anhydrous calcium sulfate, and glass beads coated with the methylene blue photosensitizer. For the control molecular oxygen experiments, the methylene blue photosensitizer was covered with aluminum foil. The light from a halogen lamp (500 W) was applied during the singlet oxygen experiments. The pulp consistency was 10%.

[0086]After a specified time, the reacted pulp was isolated on a Buchner funnel with a Whatman #41 filter paper under aspirator vacuum. The pH of the filtrate was measured between 7.9 and 9.4. The pulp was rinsed by the addition of about 500 mL D.I. water to the funnel with a...

example 3

[0088]In this example, the Parr reactor was charged as described in Example 2. The pressure manifold was prepared as described in Example 2 except that the photosensitizer was rose bengal and compressed oxygen (or compressed air) was used as the gas. The amount of MgSO4 added for sample I.D. #3A, 3B, 3C, and 3D was 0.009 g.

TABLE 3EFFECT OF HIGH PRESSURE OF MOLECULAR OXYGEN VERSUS SINGLET OXYGEN ONSOFTWOOD USING ROSE BENGAL AS THE PHOTOSENSITIZER.IntrinsicMwSelectivitySelectivitySampleViscosityKappa(g / mol)SelectivitySelectivityImprovementImprovementTAPPII.D.Description[η], mL / gNumberSECfrom [η]from Mwfrom [η], %from Mw, %Brightness3AMolecular60724.9842,00024.433,800——26.8Oxygen3BSinglet71121.3930,00033.443,70036.929.426.9Oxygen3CAir -64627.8943,00023.233,900——24.6M.O.3DAir -66526.3892,00025.333,900 8.8 0.024.1S.O.M.O. = molecular oxygen andS.O. = singlet oxygen

[0089]The data set forth for unbleached kraft softwood pulp in Table 3 for rose bengal illustrates the selectivity improvemen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com