Process for preparing chlorine dioxide for pulp bleaching and apparatus thereof

A chlorine dioxide and pulp bleaching technology, applied in chlorine oxide and other directions, can solve the problems of small preparation capacity, the process technology cannot reach the production scale, etc., and achieves large adaptability to output changes, high production capacity and reaction efficiency, and reduces emissions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

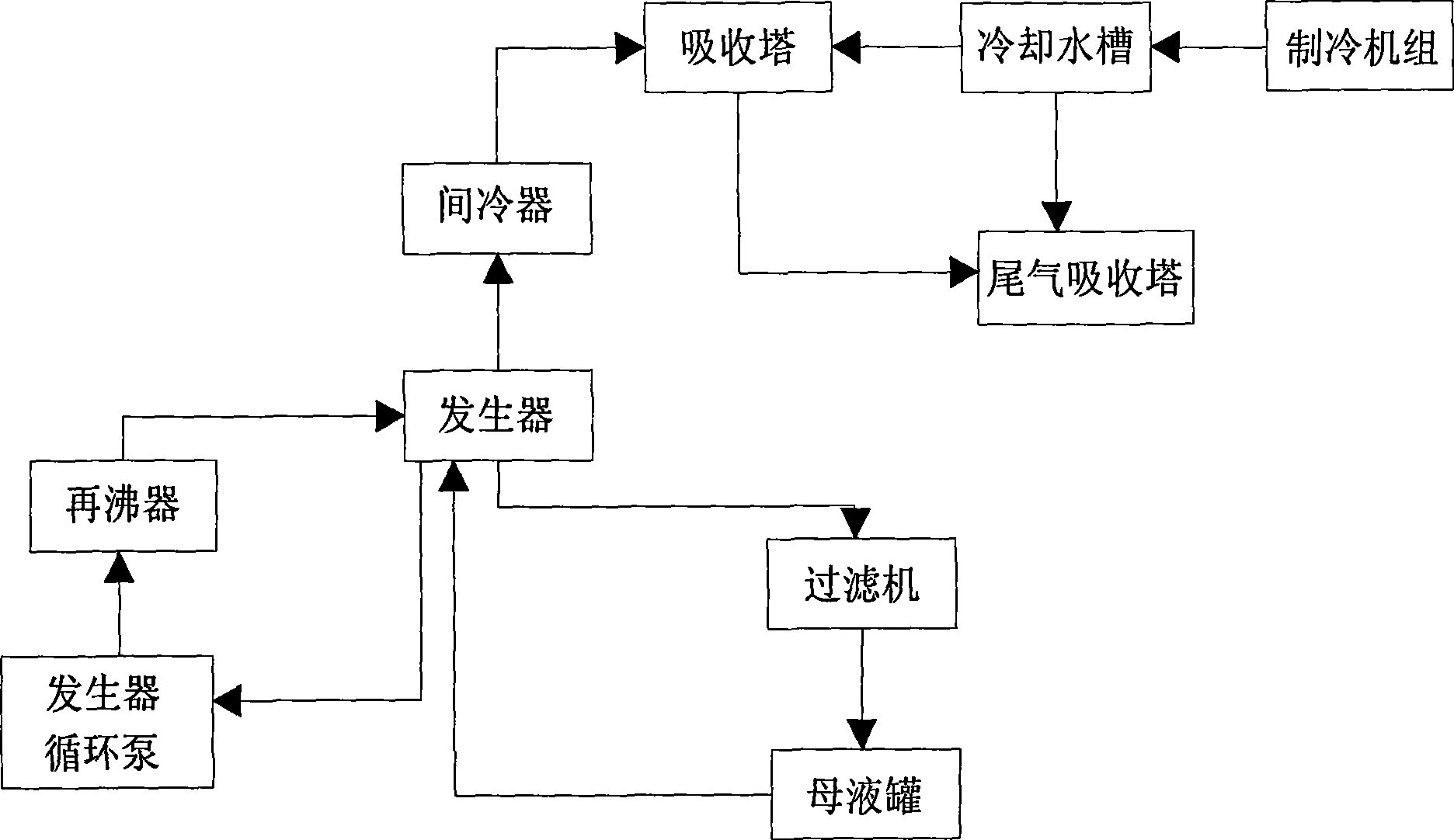

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0017] Chlorine dioxide prepared by the present invention is to be raw material with sodium chlorate, sulfuric acid, methyl alcohol, and is obtained through chemical reaction, once three kinds of raw materials are contacted in generator, the reaction represented by following reaction formula will take place:

[0018] 12NaClO 3 +8H 2 SO 4 +3CH 3 OH→12ClO 2 +9H 2 O+4Na 3 H(SO 4 ) 2 +3HCOOH

[0019] First, send the impurity-free sodium chlorate, methanol, and sulfuric acid solutions into the generator in proportion, heat and control the temperature of the generator at 71°C to 73°C. Among them, sodium chlorate is added before the inlet of the generator circulation pump, and sulfuric acid and methanol are added from the outlet of the reboiler. At the same time, the mother liquor is circulated between the generator and the reboiler through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com