Method for removing fluorescent substance in waste paper pulp

A waste paper pulp, fluorescent technology, applied in the field of bleaching treatment, can solve the problems of chemical waste, process energy consumption, no whitening effect, etc., to achieve the effect of saving investment, easy realization, energy and chemical saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

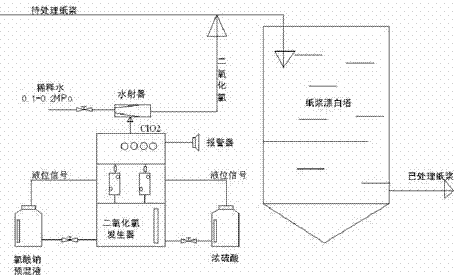

[0023] Chlorine dioxide preparation, commonly used preparation methods are:

[0024] ①, 5NaClO 2 +4HCl=4ClO 2 +5NaCl+2H 2 o

[0025] ②, NaClO 3 +2HCl=ClO 2 +1 / 2Cl 2 +NaCl+H 2 o

[0026] Methods ① and ② use NaClO 3 +HCl and NaClO 2 +HCl two reaction processes, the conversion rate of the raw material and the purity of the product are not high, and the reaction by-product Cl 2 It is not allowed by the environment.

[0027] The invention adopts novel chlorine dioxide preparation technology.

[0028] 2NaClO3+H 2 o 2 +H 2 SO 4 =2ClO 2 +O 2 +NaSO 4 +2H 2 o

[0029] The conversion rate of raw materials and the purity of products are high, and the reaction by-products are harmless to production and the environment. See figure 1 .

[0030] The present invention carries out bleaching and fluorescence removal simultaneously, and mainly comprises the following steps:

[0031] 1. Start the chlorine dioxide generator, continuously prepare chlorine dioxide online, and f...

Embodiment 1

[0037] 1. Waste paper pulp: mixed office waste paper, after deinking and bleaching

[0038] 2. Pulp concentration: 3.9%

[0039] 3. Reaction temperature: 35°C

[0040] 4. Reaction time: 30min

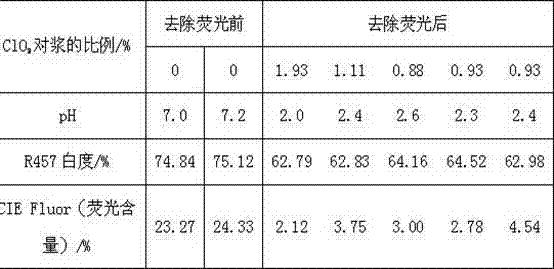

[0041] 5. The amount of chlorine dioxide and the reaction results are shown in the following table:

[0042]

[0043] It can be seen from the above table that when chlorine dioxide is used as a fluorescence remover to treat bleached waste paper pulp, a small amount of chlorine dioxide (0.88-1.93%) can reduce the fluorescence content of waste paper pulp from 23.27-24.33% to 2.12-4.54% . , but at the same time, due to the absence of fluorescence, the R457 whiteness of pulp also drops from 74.84 to 75.12% to 62.79 to 64.52%, which will affect the application of pulp (for example, it cannot be used on paper types that require higher whiteness) ).

[0044] Can only adopt technology of the present invention for this reason, is about to integrate the fluorescence removal of chlorine di...

Embodiment 2

[0046] 1. Waste paper pulp: mixed office waste paper, deinked and unbleached

[0047] 2. Pulp concentration: 7%

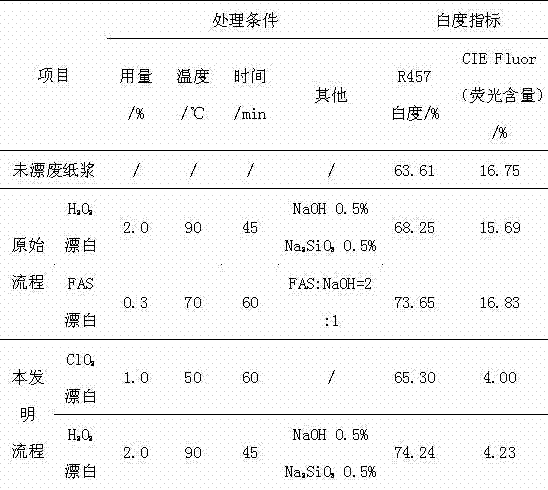

[0048] 3. Bleaching process

[0049] Original process: unbleached waste pulp→hydrogen peroxide bleaching→washing→testing brightness→FAS bleaching→washing→testing brightness

[0050] Invention process: unbleached waste paper pulp→chlorine dioxide bleaching→washing→testing brightness→hydrogen peroxide bleaching→washing→testing brightness

[0051] 4. The bleaching test results are shown in the table below:

[0052]

[0053] It can be seen from the above table that compared with the original process, the fluorescence content in the final pulp of the process of the present invention is reduced from the original 16.75% to 4.23%; and the brightness value is also 74.24%, which is not lower than the brightness of the original process of 73.65%.

[0054] It can be seen that the process of the present invention can well realize the dual effects of bleaching and fluoresce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com