Pulp Bleaching Processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

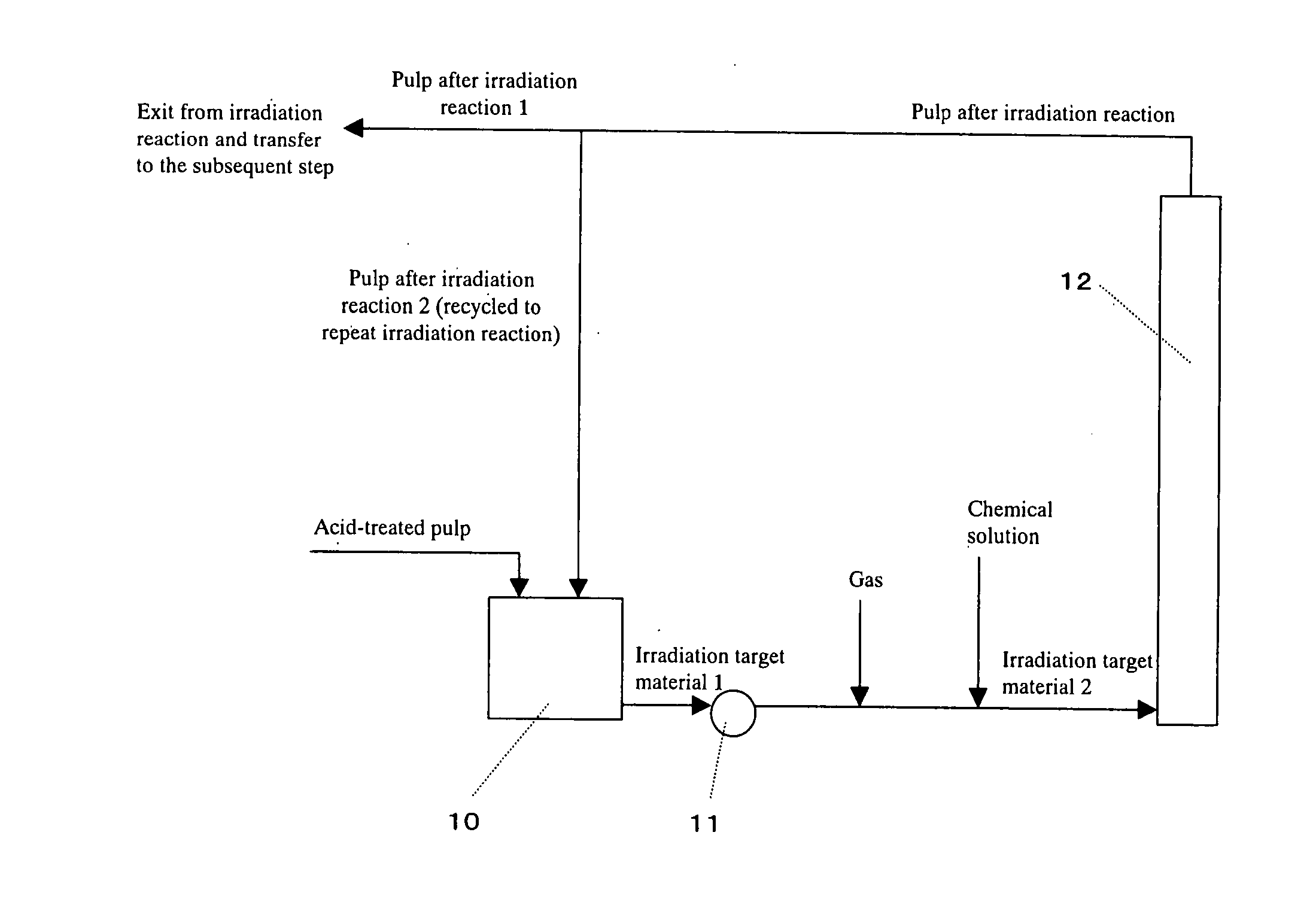

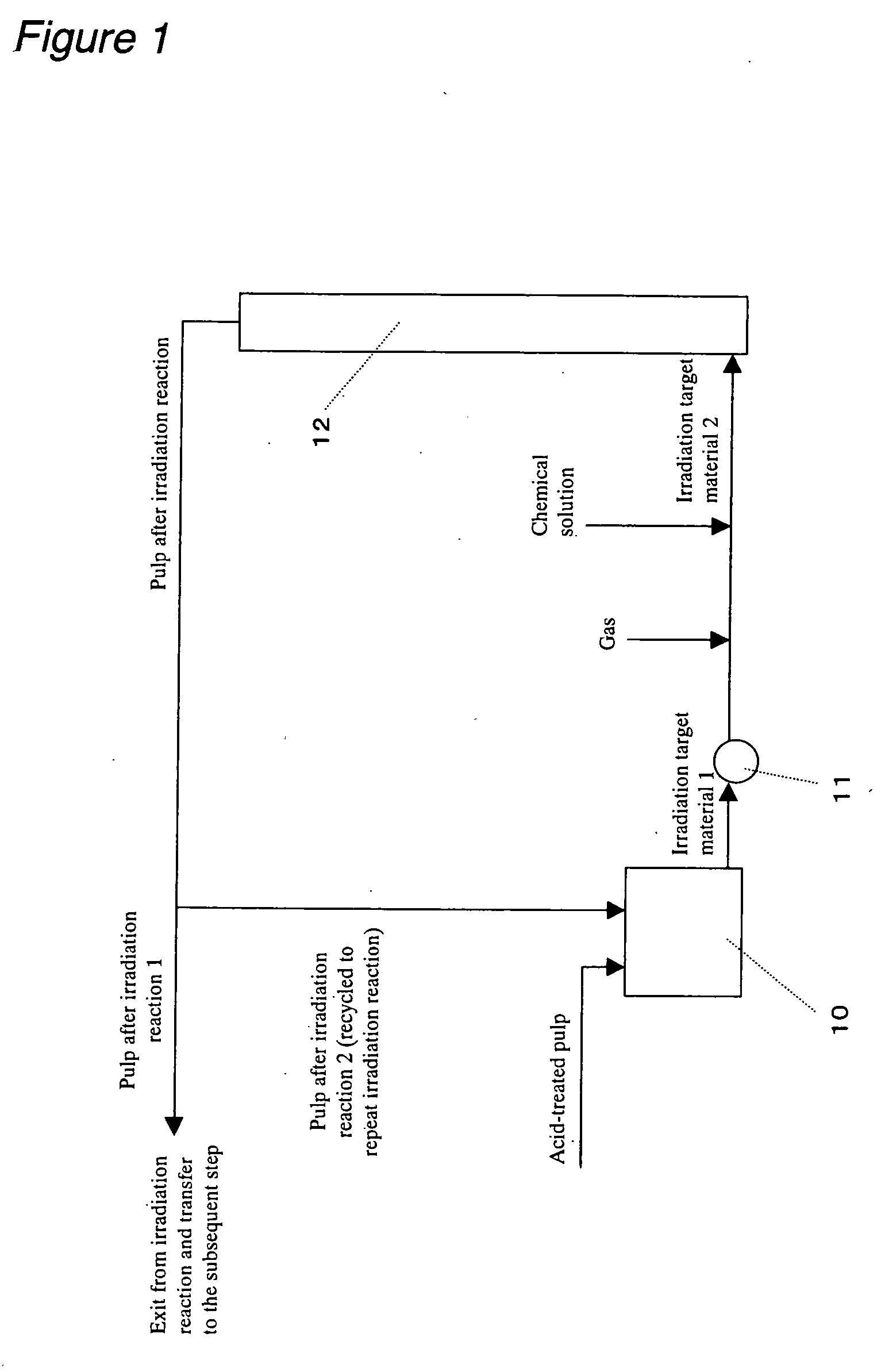

Image

Examples

example 1

[0118] An oxygen-delignified hardwood kraft pulp available from Nippon Paper Group, Inc. (kappa number 11.6, ISO brightness 45.6%) was used.

[0119] An acid treatment was performed under the following conditions to give a pulp having a kappa number of 5.5 and a brightness of 47.5%.

[0120] Acid treatment conditions: pulp consistency 10% by weight, pH 3.0 (adjusted with sulfuric acid), temperature 95° C., treatment period 180 minutes. After the treatment was completed, the pulp was washed with water.

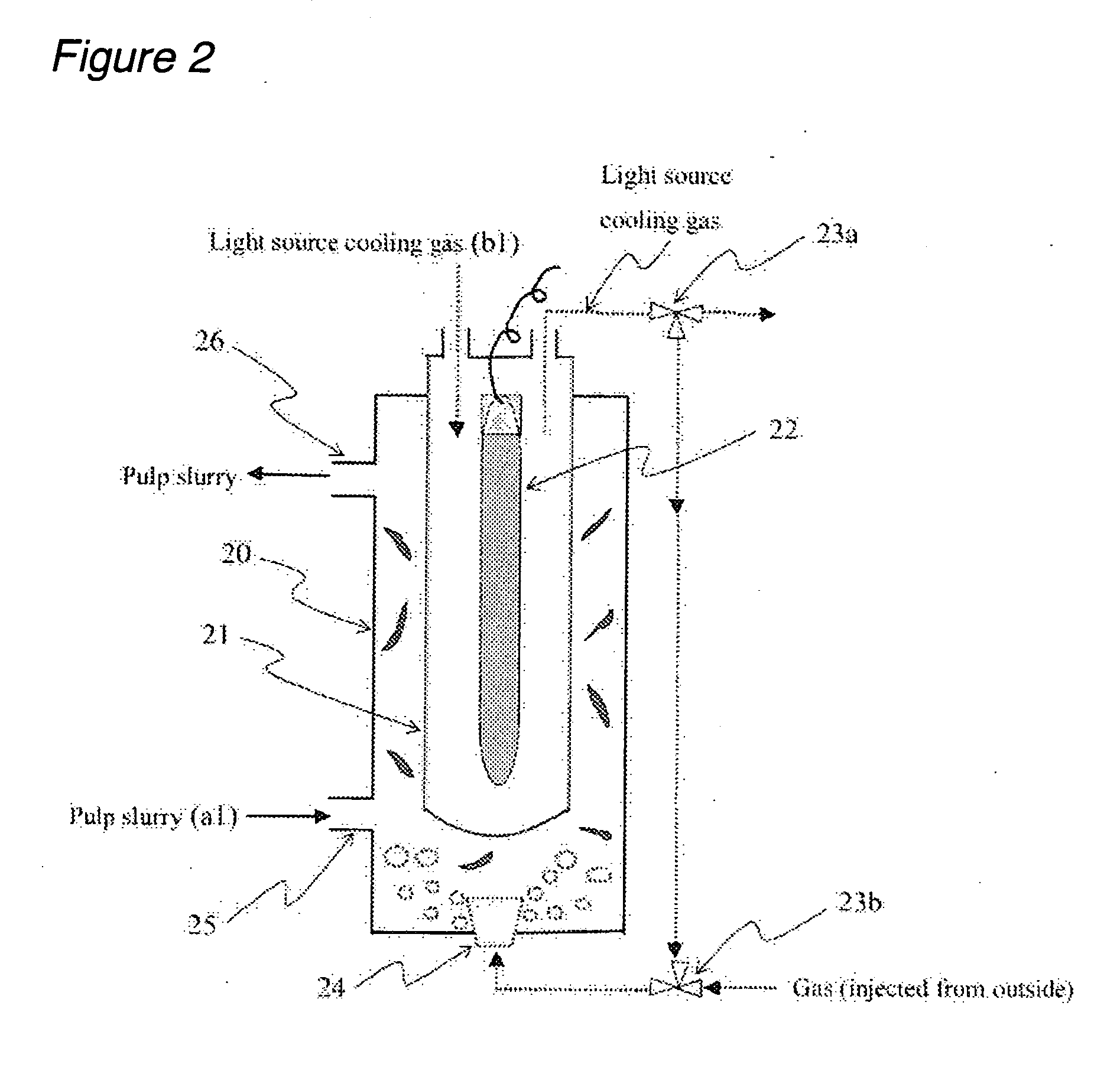

[0121] A 5 g (bone dry weight) portion of the acid-treated pulp thus obtained was collected and diluted to a pulp consistency of 0.25% by weight and then prepared into pulp slurries at pHs over an acidic to alkaline range using NaOH and H2SO4. These slurries were injected into the experimental apparatus shown in FIG. 3, and subjected to an irradiation reaction while stirring under conditions of a temperature of 25° C. for a treatment period of 120 minutes using a low-pressure UV lamp havin...

example 2

[0122] The same oxygen-delignified hardwood-kraft pulp as used in Example 1 was treated with ozone under the following conditions to give a pulp having a kappa number of 3.0 and a brightness of 56.6%.

[0123] Ozone treatment conditions: pulp consistency 10%, ozone feed 7 kg / ADTP, temperature 50° C., treatment period 30 seconds, pH 2.5 (adjusted with sulfuric acid).

[0124] A 5 g (bone dry weight) portion of the ozone-treated pulp thus obtained was collected and prepared into pulp slurries at pHs over an acidic to alkaline range and subjected to an irradiation reaction under similar conditions to those of Example 1, and the resulting pulps were measured for brightness. The results are shown in FIG. 4 and Table 1.

example 3

[0127] A 5 g (bone dry weight) portion of the same acid-treated pulp as used in Example 1 was collected and diluted to a pulp consistency of 0.25% by weight and then prepared into a pulp slurry at pH 11.5 (adjusted with NaOH and H2SO4). This slurry was injected into the experimental apparatus shown in FIG. 3, and subjected to an irradiation reaction while stirring under conditions of a temperature of 25° C. for varying treatment periods using a low-pressure UV lamp having a dominant wavelength at 254 nm. After the reaction was completed, the pulps were washed and then formed into sheets and measured for brightness. The results are shown in FIG. 5 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com