Paper pulp bleaching process

A pulp bleaching and process technology, applied in the field of pulp bleaching process, can solve problems such as high water consumption, paper industry pollution, etc., and achieve the effects of improving pulp yield, pulp polymerization degree, and folding endurance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

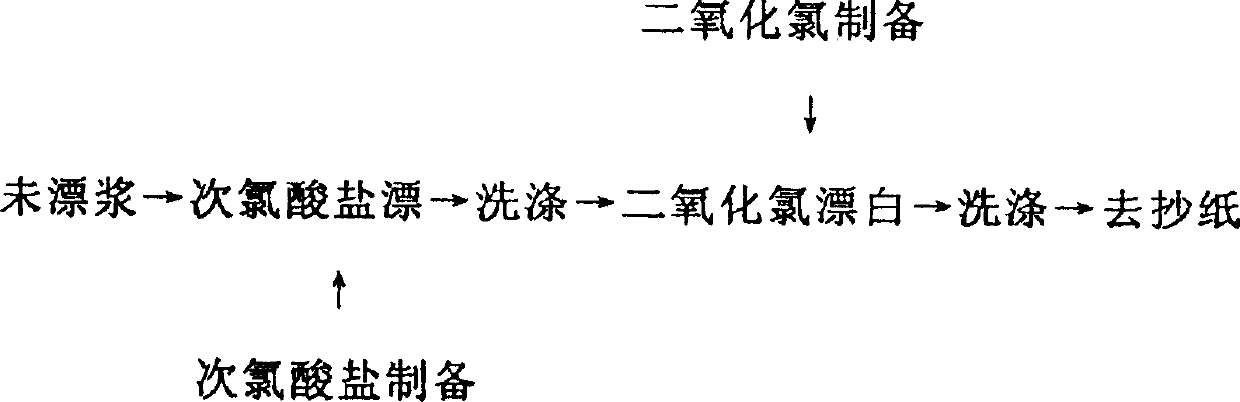

Method used

Image

Examples

Embodiment 1

[0040] Caustic soda-anthraquinone wheat straw pulp (potassium permanganate value 10) is bleached according to the following steps:

[0041] ① Section H: The concentration of straw pulp is 8%, and sodium hypochlorite is added to the straw pulp to have

[0042] Calculated effective chlorine, 5.5% (weight), initial pH 11.0, temperature 50

[0043] ℃, time 60min

[0044] ②Washing with water

[0045] ③ Section D: The concentration of washed straw pulp is 8%, and chlorine dioxide is added.

[0046] 0.7% (weight), initial pH 4.5, temperature 70°C, time 150min,

[0047] End point pH6.5

[0048] ④Washing and then papermaking process

[0049] Results: The whiteness is above 75% ISO, the fracture length is 6.8km, and the folding resistance is 220 times. Compared with CEH bleaching, it saves 30% of water, reduces COD by 50%, and reduces chroma by 70%.

Embodiment 2

[0051] In Example 1, if the HD section is not washed, the amount of chlorine dioxide is increased to 1.2%, the pulp concentration is reduced to 6%, other processes remain unchanged, and the quality index of bleached pulp remains basically unchanged, saving more than 60% of water. Example 3:

Embodiment 3

[0052] Caustic soda-anthraquinone wheat straw pulp (potassium permanganate value 12), bleach according to the following steps:

[0053] ① Section H: The concentration of straw pulp is 12%, and sodium hypochlorite is added to the straw pulp to obtain available chlorine.

[0054] Calculated, it is 7% (weight), the initial pH is 12, the temperature is 60℃, and the time is 30min

[0055] ②Washing with water

[0056] ③ Section D: The concentration of the straw pulp after washing is 12%, and chlorine dioxide is added in the amount of straw

[0057] 0.5% of pulp weight percentage, initial pH4, temperature 70℃, time 150min, final

[0058] Point pH6

[0059] ④Washing and then papermaking process. Results: whiteness above 75% ISO, length of rupture 6.0km, folding resistance 180 times, compared with CEH bleaching, 30% water saving, 50% reduction in COD, and 70% reduction in chroma .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com