Reinforcing fiber for making paper and preparing method thereof as well as paper product containing the same

A technology for reinforcing fiber and paper products, applied in the direction of synthetic cellulose/non-cellulose material pulp/paper, papermaking, textiles and papermaking, etc., which can solve the problems of limited chemical fiber application and performance, low fiber bonding strength of paper sheets, difficult fiber Uniform dispersion and other issues to achieve the effect of improving hydrophilicity and wettability, increasing strength, and enhancing binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Based on the total mass of raw materials, 1.25wt.% of cationic polyacrylamide (molecular weight of 400,000-800,000), 3.75wt.% of low-molecular-weight strong cationic polymer quaternary ammonium salt Fx-706 (New East Asia Chemical Products Co., Ltd.) and 95wt.% of PVA (average degree of polymerization of 2200, alcoholysis degree of 99mol%) were sequentially added to water to make 15% of PVA modified spinning dope.

[0026] (2) Pass the PVA modified spinning dope obtained in (1) above through a spinneret with 10,000 circular spinnerets with a diameter of 70 μm, and press into sodium sulfate (30% solid content) as a coagulant In the coagulation bath (90℃), the fabricated fiber is wound with the first roller, and the tension between the metal plate of the spinneret and the first roller is controlled between 0.040-0.055N / dtex, and then 3 times Processes such as wet stretching, stretching heat treatment (drawing temperature 200°C), oiling, etc., are used to prepare reinforci...

Embodiment 2

[0030] (1) Based on the total mass of raw materials, 0.8% amphoteric polyacrylamide (molecular weight 600,000-800,000), 1.0% CMC (carboxymethyl cellulose, DS: 0.6-0.9) and 98.2% PVA (average degree of polymerization of 2200, alcoholysis degree of 99 mol%) was sequentially added to water to make 15% PVA modified spinning dope.

[0031] (2) The PVA modified spinning dope obtained in (1) above was spun according to the same method as described in step (2) in Example 1 and subjected to 4 times wet drawing and drawing heat treatment (drawing temperature 220 ℃), oiling and other processes to make reinforcing fibers for papermaking. The reinforced fiber for papermaking has a fineness of 1.95 dtex and a strength of 8.3 cN / dtex.

[0032] (3) The reinforcing fiber for papermaking obtained in (2) above was made into paper according to the same method as described in step (3) in Example 1.

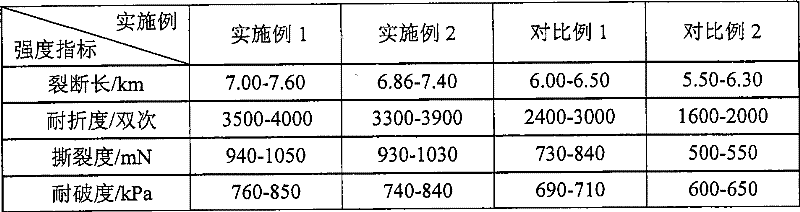

[0033] (4) The strength index of the paper added with the reinforcing fiber for papermaking and the sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com