High water resistance straw lining paper and preparation method thereof

A water-based, straw-based technology, applied in the field of papermaking, can solve problems such as refractory degradation and environmental pollution, and achieve the effects of blocking diffusion, short curing time, and reducing false sizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

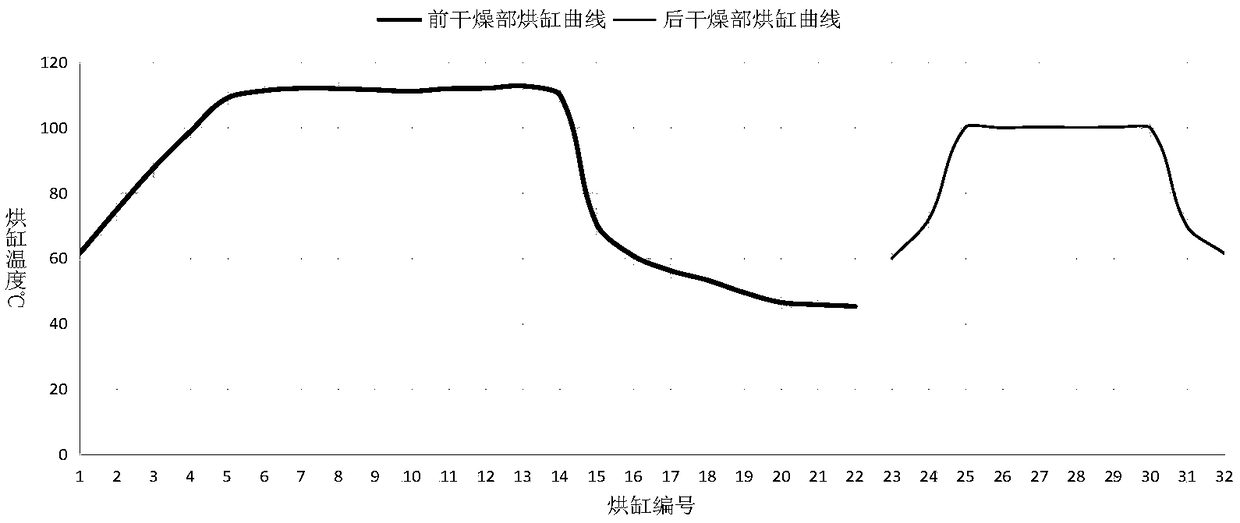

Image

Examples

preparation example Construction

[0024] A preparation method of highly water-resistant straw backing paper, comprising the following steps:

[0025] Step 1: Mix and pulp the bleached softwood pulp and bleached hardwood pulp, pump the pulp to the pulp tank after disc grinding and beating, add the filler suspension and mix evenly, then pump it to the pulp tank, add cationic starch, wet After the strong agent is mixed evenly, it is pumped to the milling pool. After the slurry is thickened and slag removed, the sizing agent and multi-component retention aid are added and then enters the headbox;

[0026] Bleached coniferous wood pulp and bleached hardwood pulp are mixed according to the ratio of (3:7)~(6:4), the soaking time before beating is 4~6h, the beating concentration is 4.0~4.7%, and the beating degree is 35~40°SR ;

[0027] The filler suspension is mixed with one or more of calcium carbonate, talcum powder, kaolin and titanium dioxide in any ratio, the concentration of the suspension is 8-12%, and the fi...

Embodiment 1

[0038]Step 1, mix bleached softwood pulp and bleached hardwood pulp in a ratio of 3:7, and then grind and beat. The soaking time before beating is 4 hours, the beating concentration is 4.0%, and the beating degree is 35°SR. Finally, the slurry is pumped to the slurry tank; add calcium carbonate filler suspension, the suspension concentration is 8%, and the filling amount is 15%, and after mixing evenly, pump it to the slurry tank; add cationic starch 0.3% (for absolute dry fiber consumption), polyamide epichlorohydrin 0.4% (to the absolute dry fiber consumption), pumped to the papermaking pool after mixing evenly; after the slurry was thickened and slag removed, alkenyl succinic anhydride ( ASA) emulsion, the consumption is 0.4% (to the absolute dry fiber consumption); ASA emulsion field emulsification step is to adjust the pH to 4 with citric acid after starch gelatinization, mix with ASA after cooling to 40 ℃, use high-shear turbine Pump emulsification makes sizing agent emu...

Embodiment 2

[0042] Step 1: Mix bleached coniferous wood pulp and bleached hardwood pulp in a ratio of 4:6, and then grind and beat. The soaking time before beating is 5 hours, the beating concentration is 4.5%, and the beating degree is 38°SR. Finally, the slurry is pumped to the slurry tank; add kaolin and titanium dioxide 3:1 filler suspension, the suspension concentration is 8%, and the filling amount is 18%, mix well and then pump to the slurry tank; add cationic starch 0.5% (Amount for absolute dry fiber), polyamide epichlorohydrin 0.5% (Amount for absolute dry fiber), mix evenly and pump to the papermaking pool; After the slurry is thickened and slag removed, it is continuously added at the exit of a good pulp Alkenyl succinic anhydride (ASA) emulsion, the dosage is 0.2% (for absolute dry fiber); the on-site emulsification step of ASA emulsion is to adjust the pH to 4.5 with citric acid after starch gelatinization, and mix it with ASA after cooling to 43°C. The sizing agent emulsion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com