Double-circulation biological membrane anaerobic ammonia oxidation reactor

An anaerobic ammonium oxidation and reactor technology, which is applied in anaerobic digestion treatment, chemical instruments and methods, water pollutants, etc., can solve the problems of increasing equipment costs and power consumption, long reactor start-up time, and destroying sludge structure, etc. problems, to achieve the effect of easy disassembly, reduce power consumption, and alleviate interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

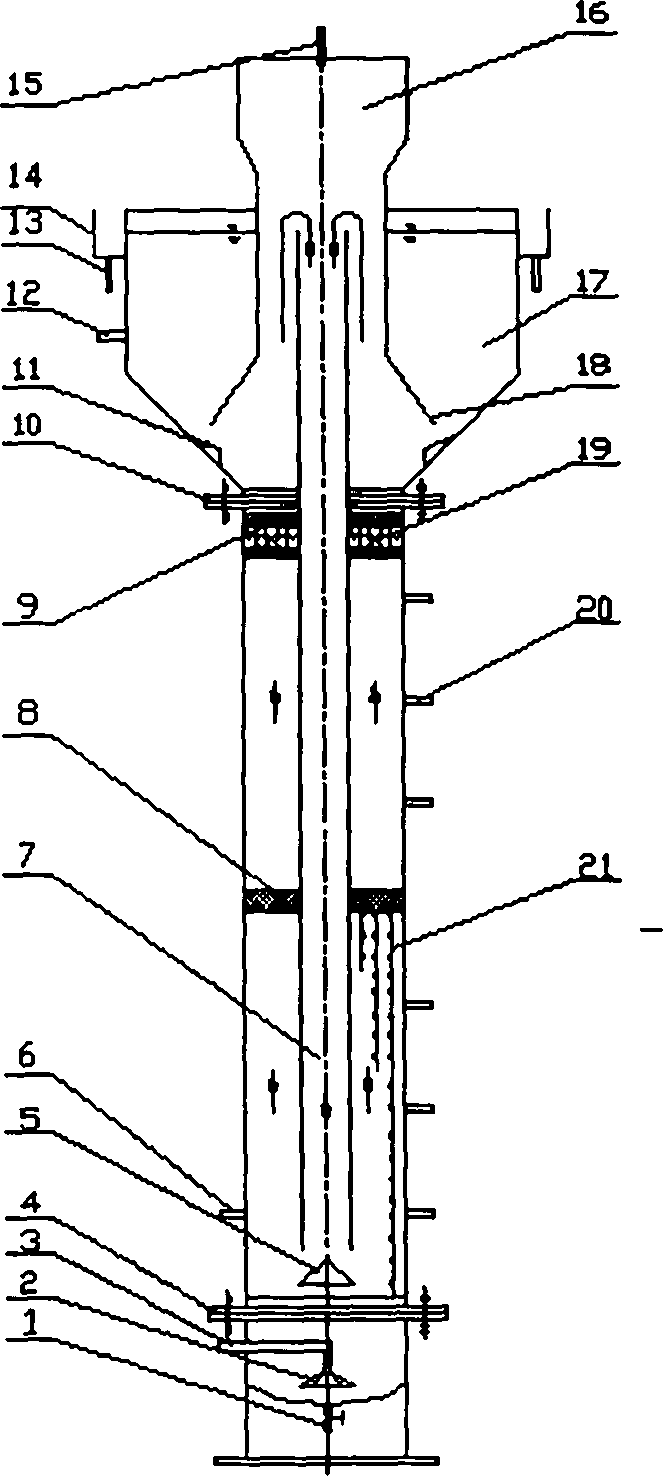

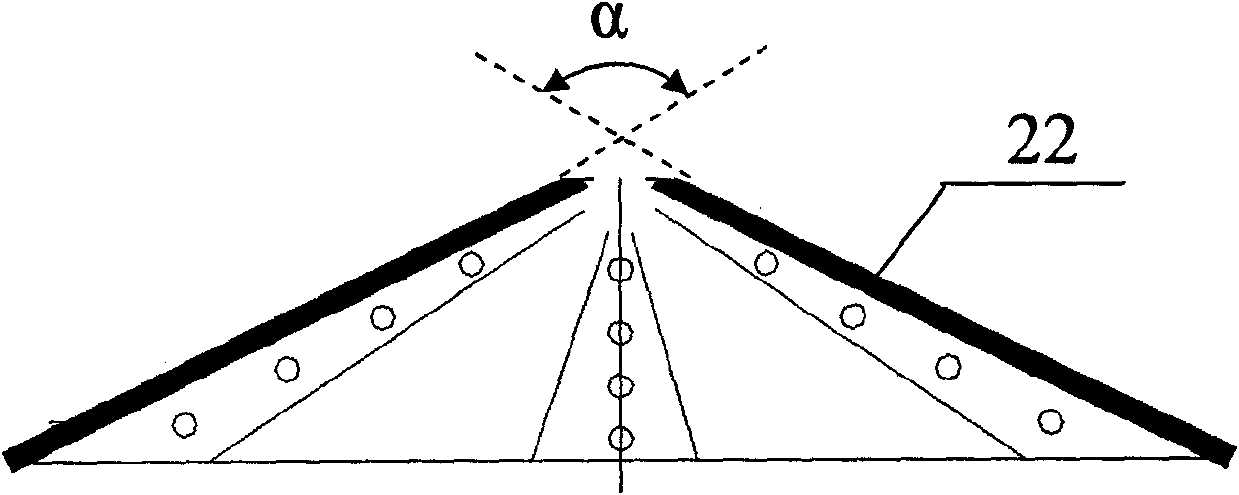

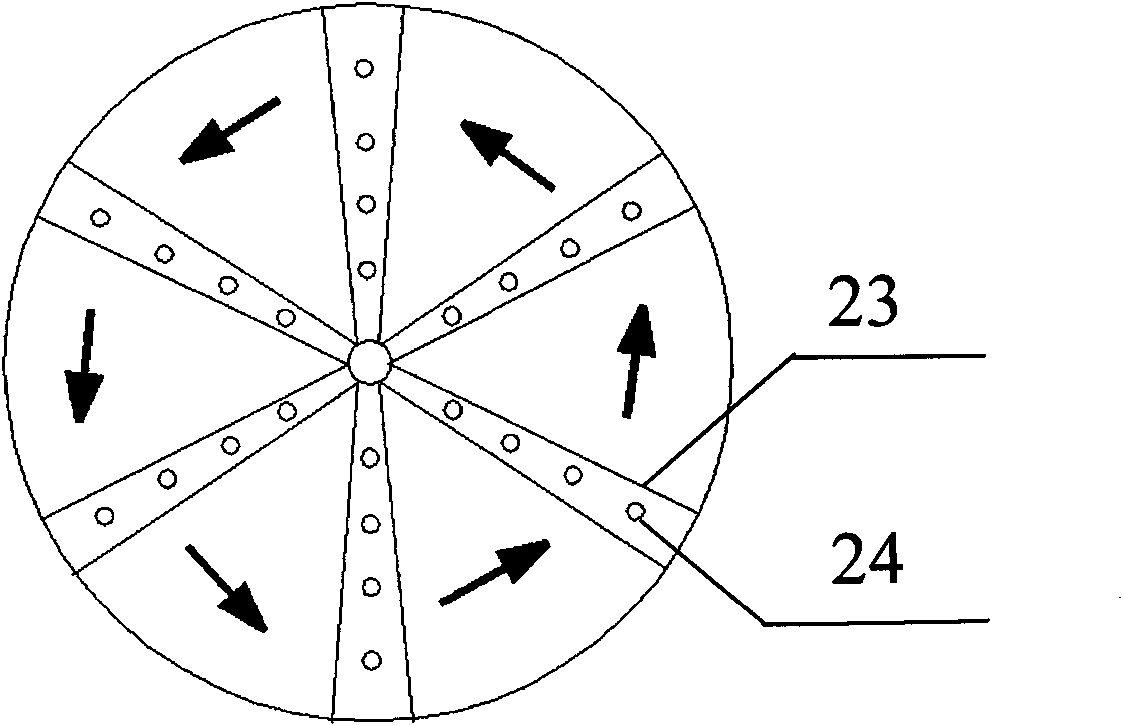

[0017] As shown in the figure, the dual-cycle biofilm anammox reactor includes a sludge discharge pipe 1, a swirling water distributor 2, an inlet pipe 3, a first flange 4, an outflow baffle 5, a return inlet pipe 6, and a downcomer 7. Coarse screen 8, fine screen 9, second flange 10, baffle plate 11, backflow outlet pipe 12, backflow outlet pipe 13, overflow weir 14, air guide pipe 15, air chamber 16, three-phase separator 17, Settling area 18, floating ball 19, sampling port 20, soft packing 21, swirl hood 22, rotary water distribution plate 23 and water distribution port 24; there is a sludge discharge pipe 1 at the bottom of the reactor, and the inside of the reactor body is from bottom to top Sludge discharge pipe 1, swirl water distributor 2, water inlet pipe 3, first flange 4, outflow baffle 5, soft packing 20, coarse screen 8, fine screen 9, floating ball 18, the first Two flanges 10, baffle plate 11 and three-phase separator 17, the outer side of the three-phase separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com