Biomass preventing corrosion of superheater and garbage power generation boiler

A waste-to-energy and biomass technology, applied to steam boilers, steam generation, lighting and heating equipment, etc., can solve problems such as reducing boiler life, accelerating corrosion, superheater corrosion, etc., achieving simple construction and maintenance, and reducing chlorine content , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

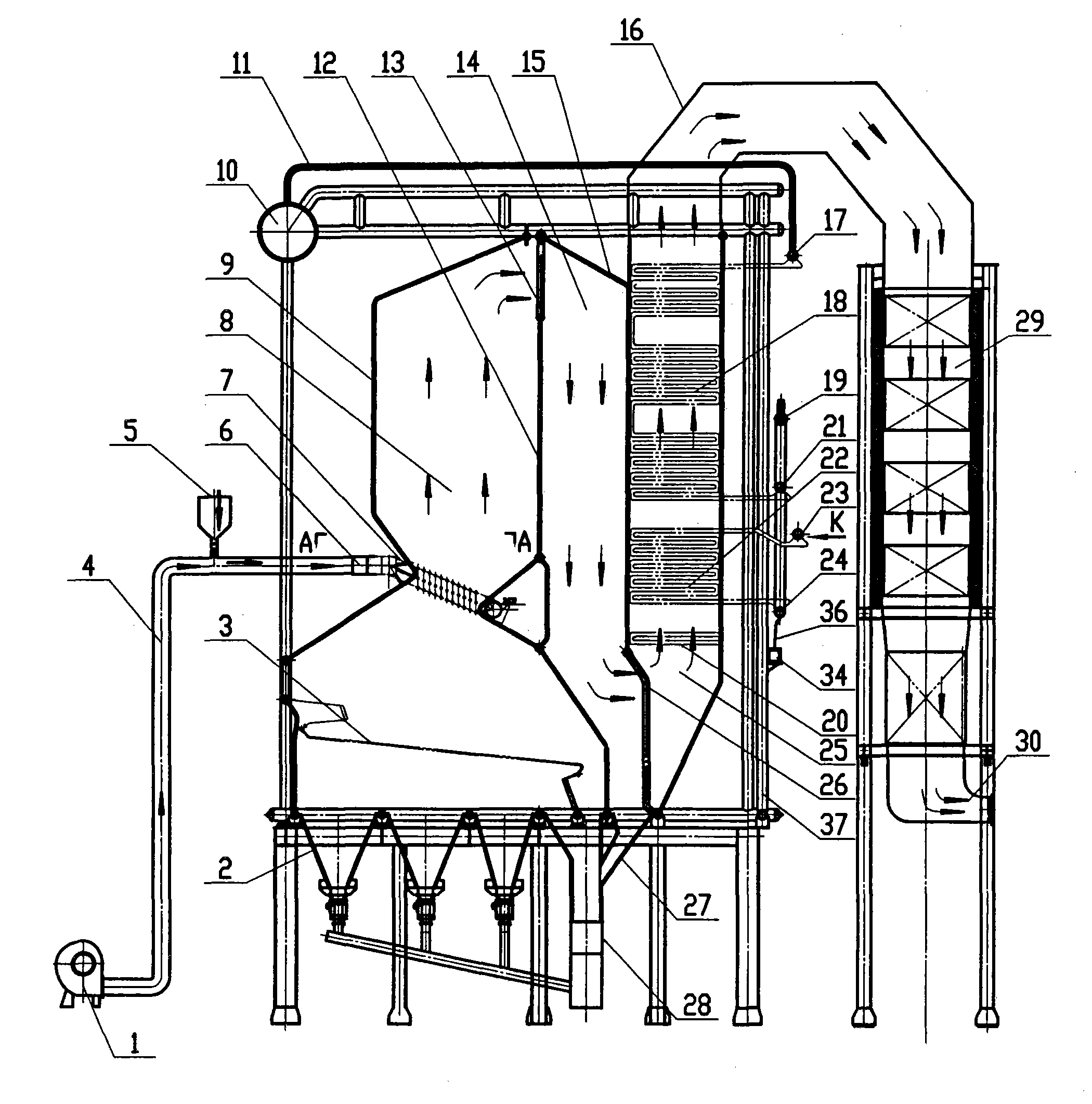

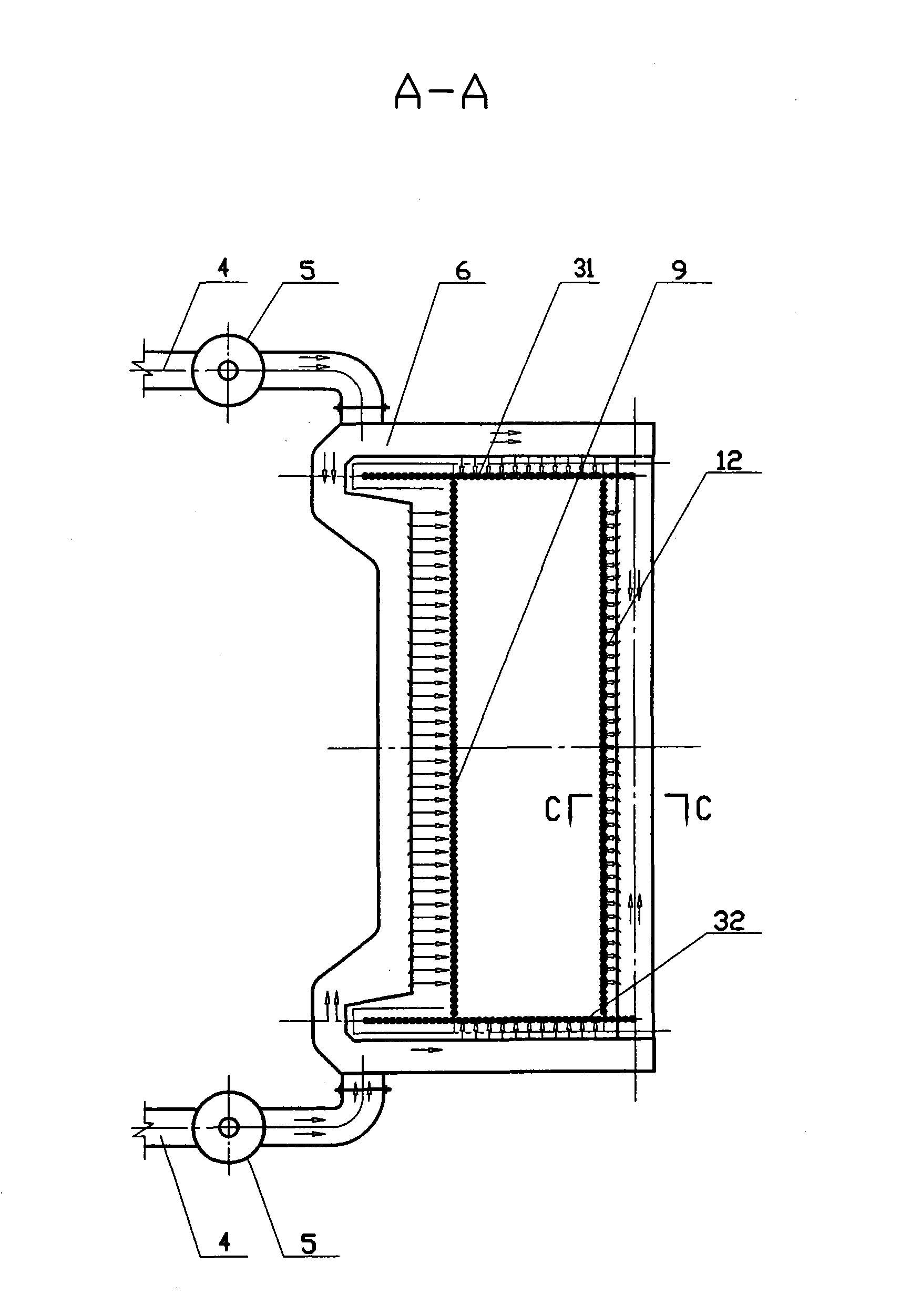

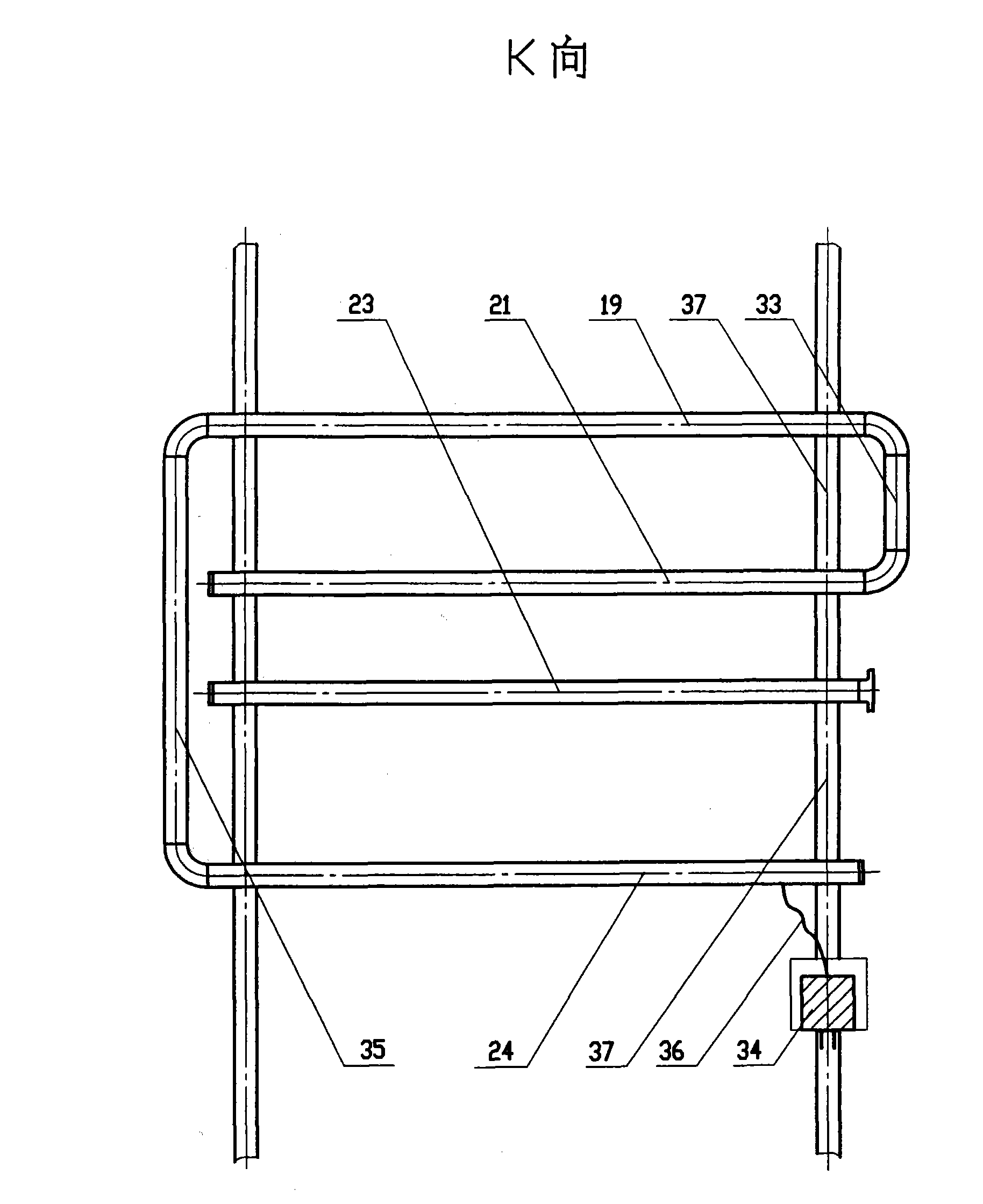

[0029] Example 1: A 75t waste-to-energy boiler that prevents superheater corrosion, including the body of the waste-to-energy boiler, wherein the secondary air box is arranged around the arch of the furnace 8 to form a surrounding secondary air; on the secondary air main pipe 4, set A limestone powder funnel 5 with a material control valve; the distance between the front and rear arches of the furnace 8 is 2m; the convection low-temperature superheater pipe 18 and the high-temperature superheater pipe 22 are arranged in the shaft flue II 25; On the pipe wall of the downcomer 37 at the inlet header 24 of the device, a box body is arranged, and the box body is fixedly connected with the pipe wall of the downcomer 37, and a zinc block 34 is placed in the box, and is connected to the inlet of the high-temperature superheater through a copper wire. The headers 24 are connected.

Embodiment 2

[0030] Example 2: A 35t biomass power boiler that prevents superheater corrosion, including the body of the biomass power boiler, wherein the secondary air box is arranged around the arch of the furnace 8 to form a surrounding secondary air, on the secondary air main pipe 4 , a limestone powder funnel 5 with a material control valve is set, the distance between the front and rear arches of the furnace 8 is: 1.5m; the convection low-temperature superheater tube 18 and the high-temperature superheater tube 22 are arranged in the shaft flue II 25; On the tube wall of the downcomer 37 near the inlet header 24 of the high-temperature superheater, a box body is arranged, and the box body is fixedly connected with the tube wall of the downcomer 37, and a zinc block 34 is placed in the box, and the copper wire and the The inlet headers 24 of the high temperature superheater are connected to each other.

Embodiment 3

[0031] Embodiment 3: A 20t biomass power boiler for preventing superheater corrosion, including a biomass power boiler body, wherein a box is set on the tube wall of the downcomer 37 near the inlet header 24 of the high temperature superheater. It is fixedly connected with the pipe wall of the downcomer 37, and a zinc block 34 is placed in the box, and is connected with the inlet header 24 of the high-temperature superheater through a copper wire 36.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com