Pulverized coal or water coal slurry gasification furnace system

A gasification furnace and coal-water slurry technology, which is applied in the gasification of granular/powdered fuels, the manufacture of combustible gases, and the petroleum industry. It can solve the problems of increasing system load, affecting stable operation, and syngas carrying liquid To achieve the effect of prolonging the operation cycle, prolonging the service life, and reducing the water and ash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

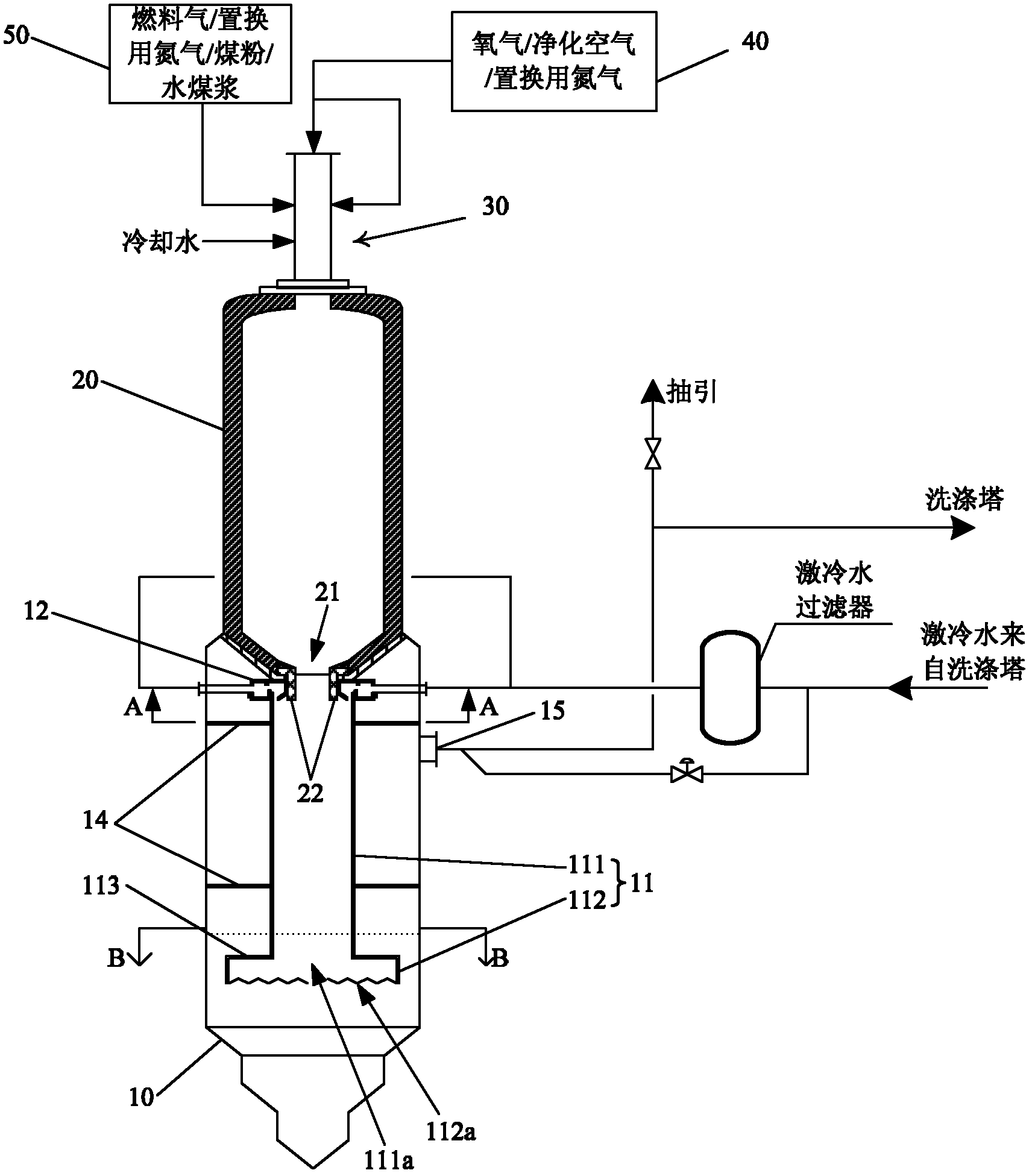

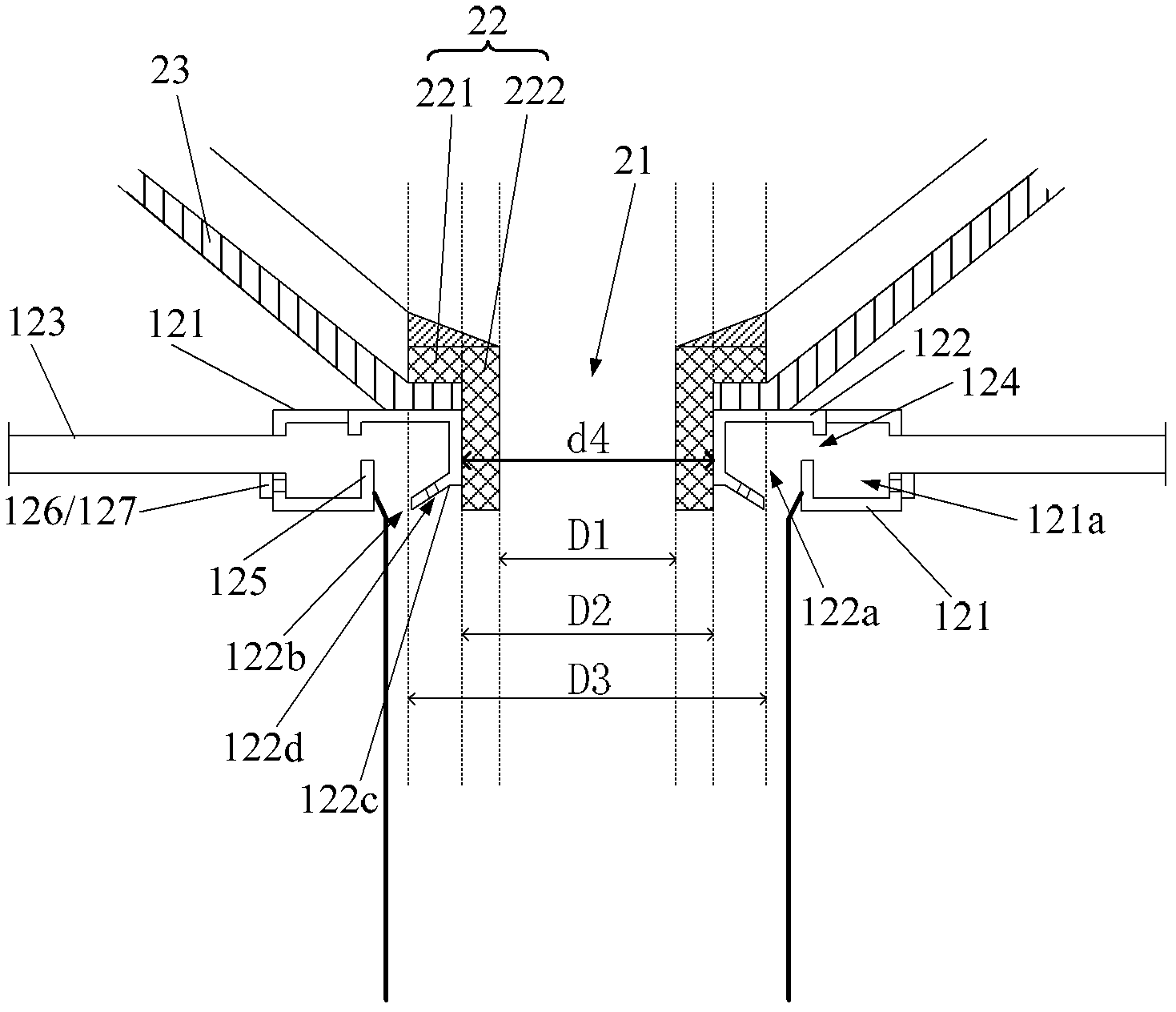

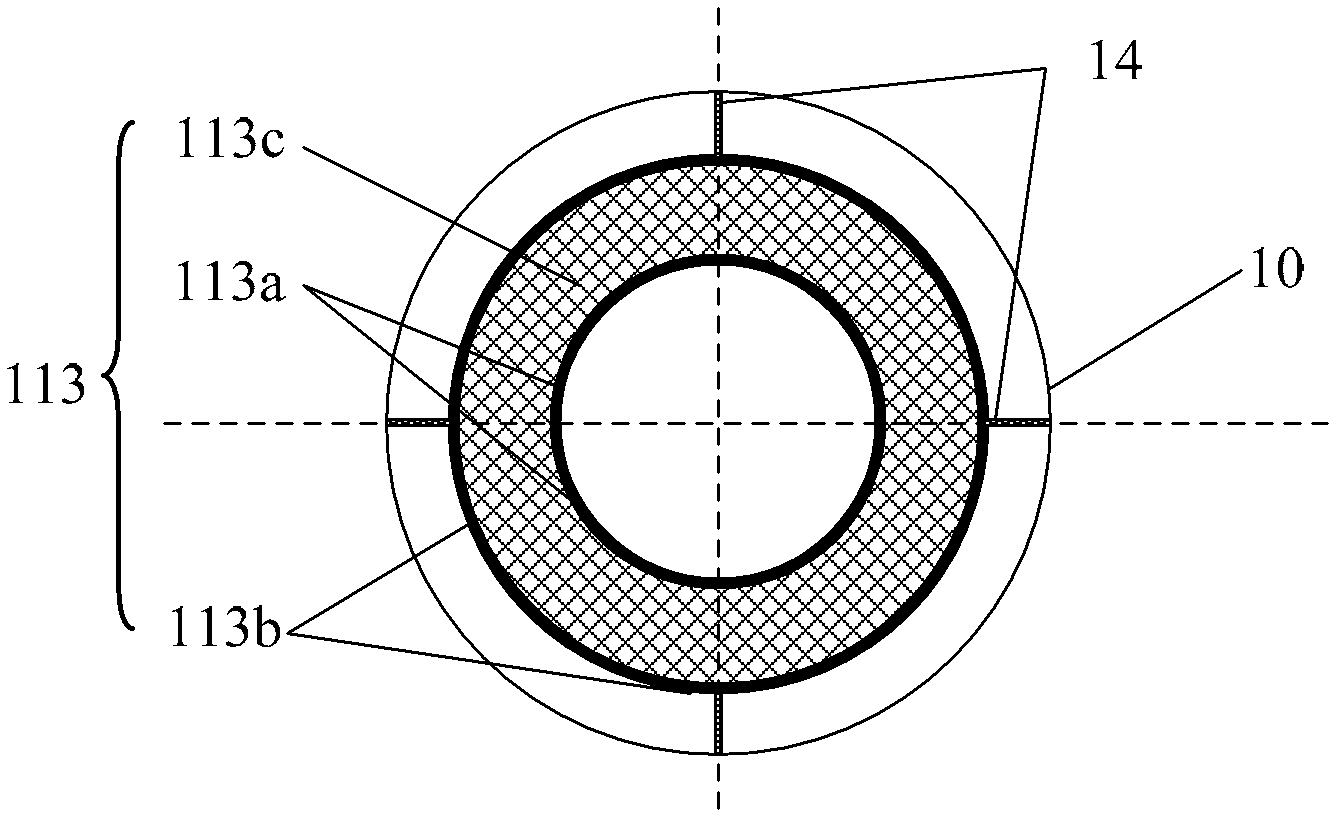

[0077] figure 1 is a schematic structural diagram of a gasifier system according to an embodiment of the present invention. like figure 1 As shown, the gasification furnace system includes a gasification furnace, a feeding system for feeding into the gasification furnace, and a subsequent treatment system for the compound gas released from the furnace, wherein the gasification furnace includes a combustion chamber 20, a quenching chamber 10 located below the combustion chamber, and the combustion chamber The top of the chamber 20 is provided with a composite burner 30, and the bottom is provided with a slag port 21. The quenching chamber is provided with a downcomer 11 and a quenching ring 12 that provides quenching water at the top of the downcome...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com