Gasification furnace and chilling chamber thereof

A chilling chamber and gasifier technology, which is applied in the gasification of granular/powdered fuels, the manufacture of combustible gas, and the petroleum industry. It can solve problems such as fluctuations in the liquid level of the chilling chamber, fluctuations, and increased chilling water supply flow. , to achieve the effect of reducing the content of fine solid particles, increasing the washing area, and inhibiting the phenomenon of water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

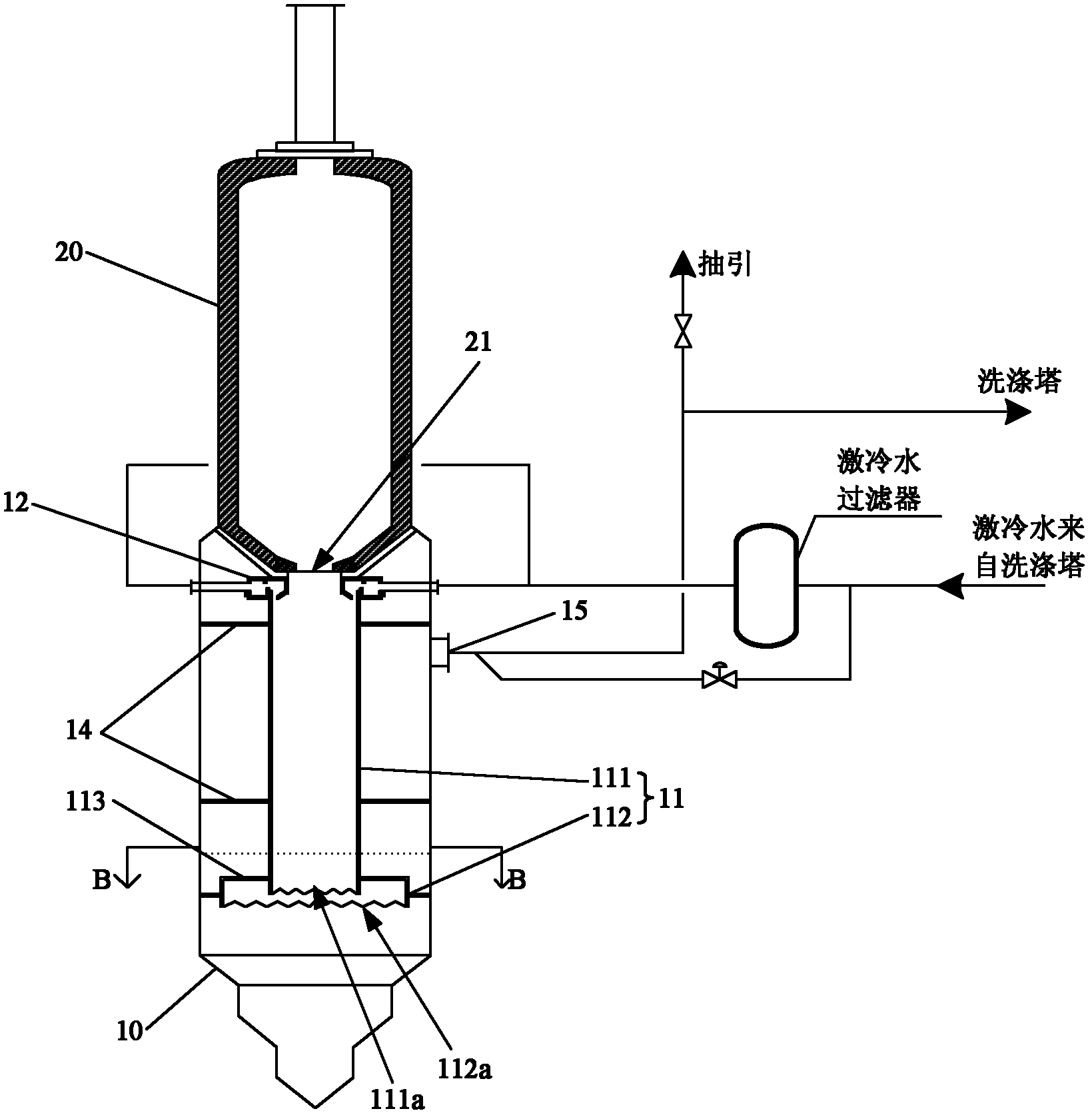

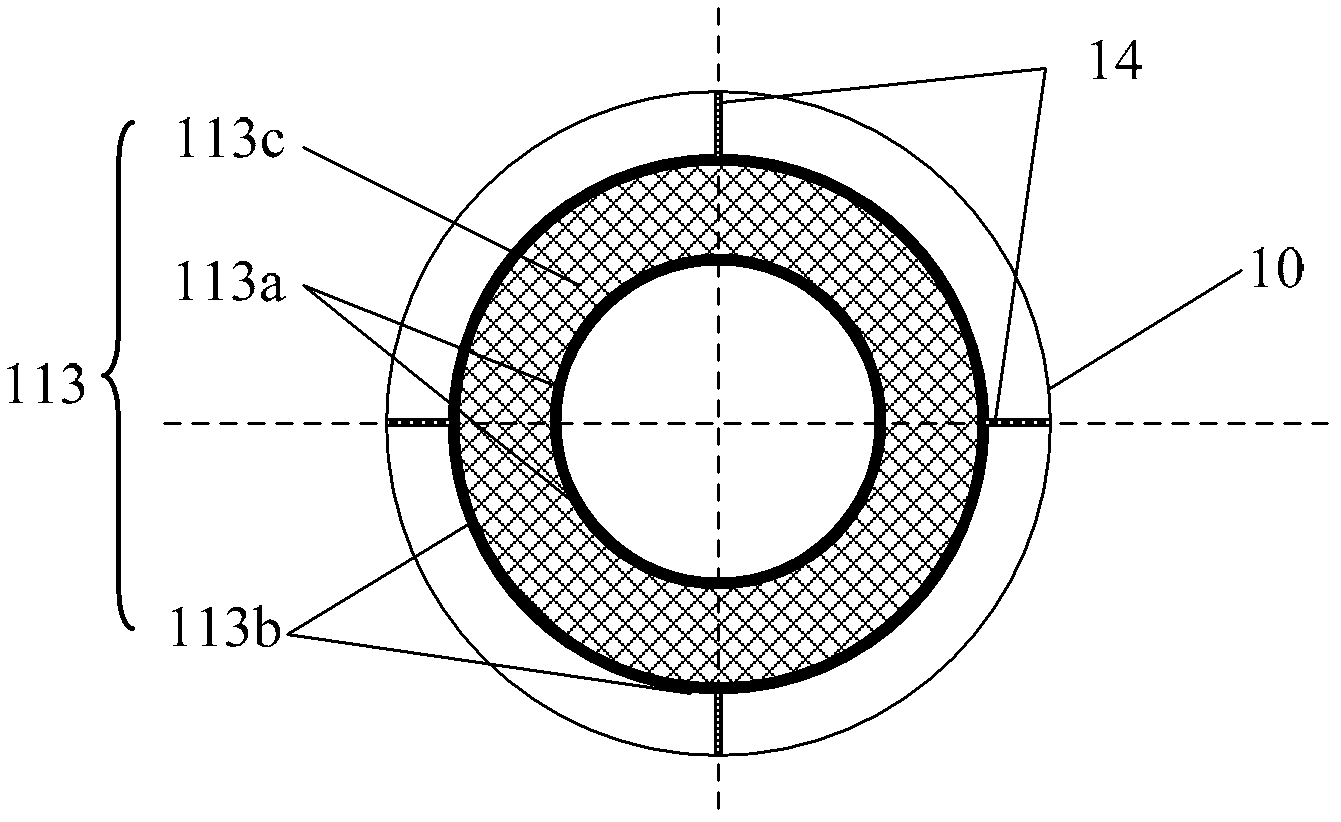

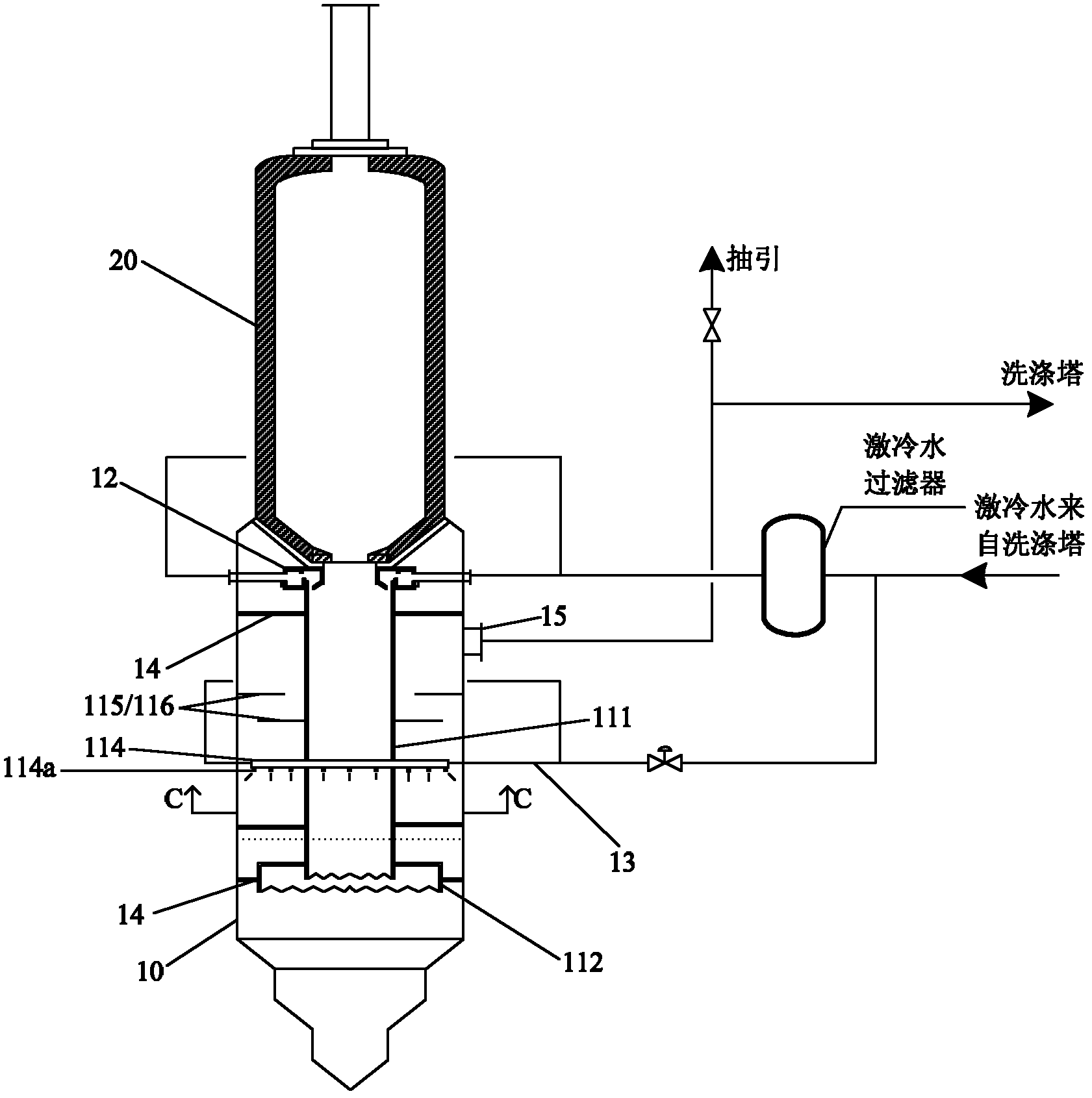

[0047] figure 1 and figure 2 A schematic structure of a fluidized gasifier according to a first embodiment of the present invention is shown. Such as figure 1 and figure 2 As shown, the gasification furnace includes a combustion chamber 20 and a quench chamber 10 located below the combustion chamber. The high-temperature syngas and molten slag in the combustion chamber 20 enter the downcomer 11 through the slag port 21 at the bottom.

[0048]In this embodiment, the double-sleeve structure of the concentric and coaxial ascending pipe and descending pipe of the prior art is not adopted, and only the descending pipe is reserved. The sleeve structure of the connected part is fixedly connected with the inner wall of the quenching chamber by the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com