Gasification furnace chilling chamber and gasification furnace

A technology for chilling chamber and gasifier, which is used in the gasification of granular/powdered fuel, the manufacture of combustible gas, and the petroleum industry. The degree of automation and other issues can achieve good dust removal and ash purification effect, improve cooling and purification effect, and inhibit the effect of water-carrying phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

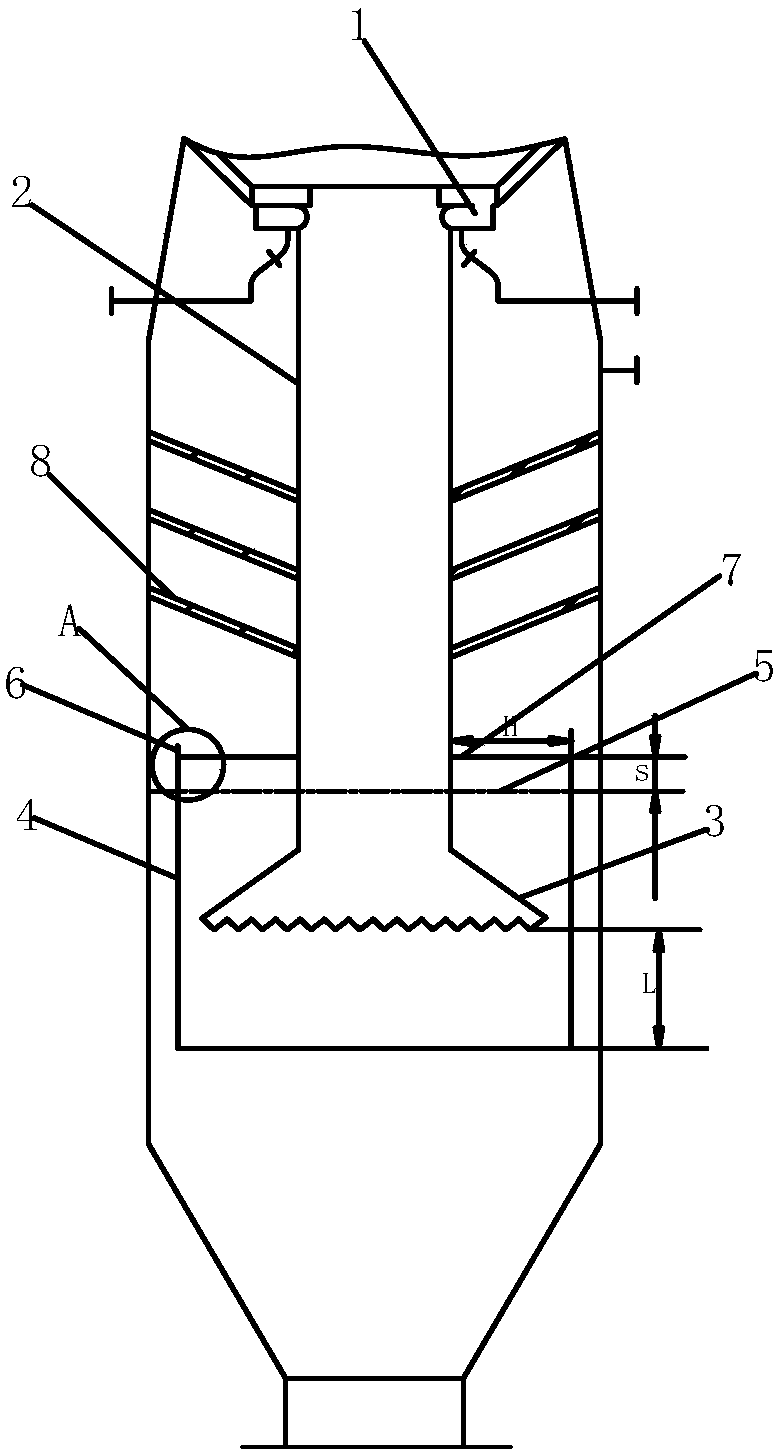

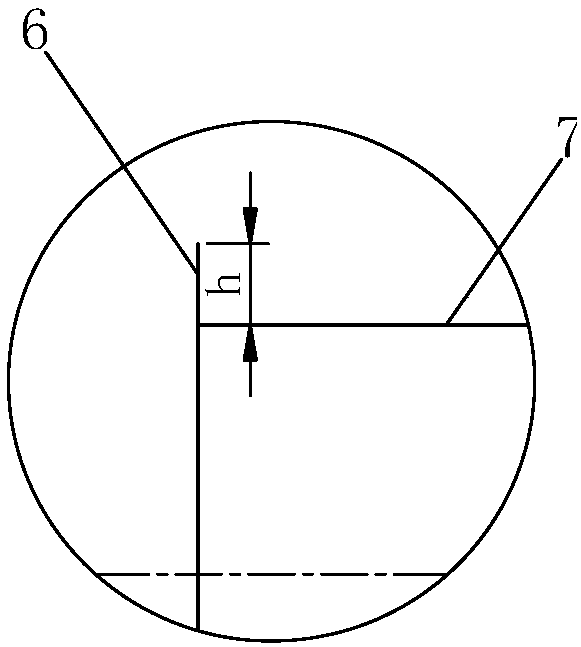

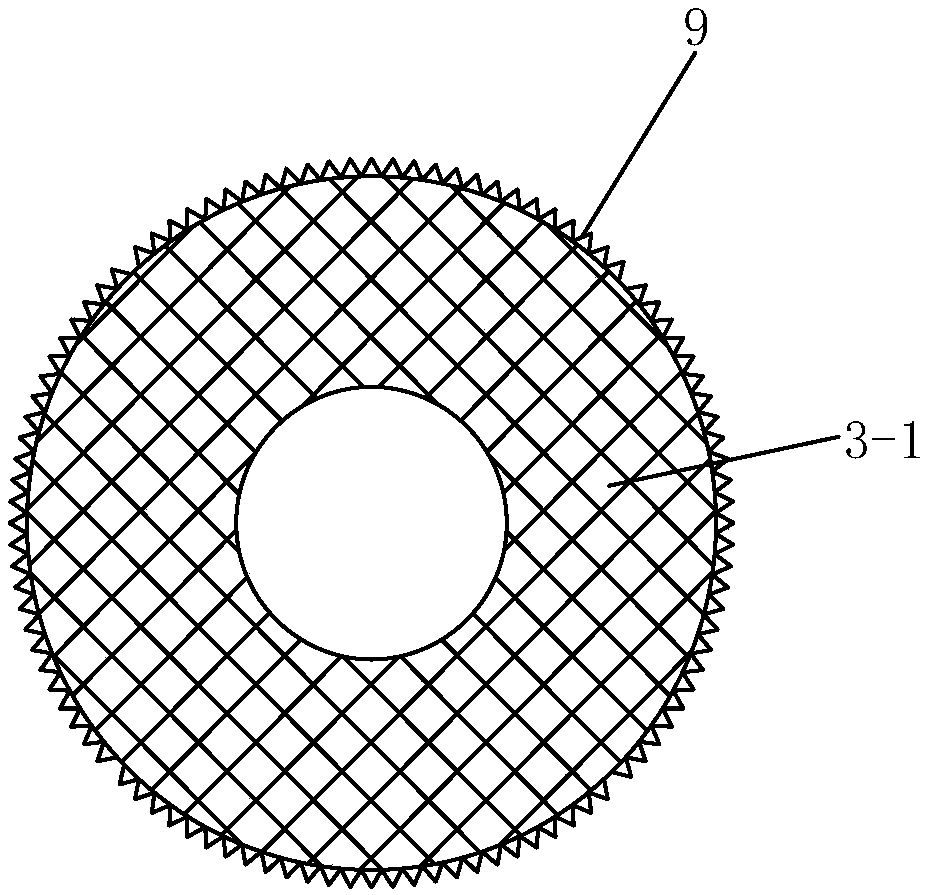

[0037] Such as Figure 1 to Figure 9 The chilling chamber of a gasification furnace shown includes a downgas cylinder 2 and a gas distribution cylinder 4, the lower end of the downgas cylinder 2 extends into the gas distribution cylinder 4, and an air diffuser net is arranged in the annular cavity between the downgas cylinder 2 and the gas distribution cylinder 4 7. The outer edge of the diffuser 7 has an overflow weir 6. The plane where the diffuser 7 is located is higher than the liquid level 5 of the quenching chamber. The bottom of the downgas cylinder 2 is provided with a bubble breaking cylinder 3 that communicates with the downgas cylinder 2. The bubble breaking cylinder 3 is located below the liquid surface 5 of the quenching chamber, and the annular cavity between the downgas cylinder 2 and the inner wall of the quenching chamber is provided with a multi-layer swirl flow guide 8, and the multi-layer swirl flow guide 8 is arranged along the The height direction of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com