Nuclear reactor fuel assembly bottom nozzle hydraulic scouring test system and test method thereof

A technology of nuclear reactor fuel and test system, which is applied in the field of hydraulic scouring test system of tube seat under nuclear reactor fuel assembly, can solve problems such as inapplicability or unsatisfaction, and achieve the effects of preventing temperature rise, high transparency, and realizing visual research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

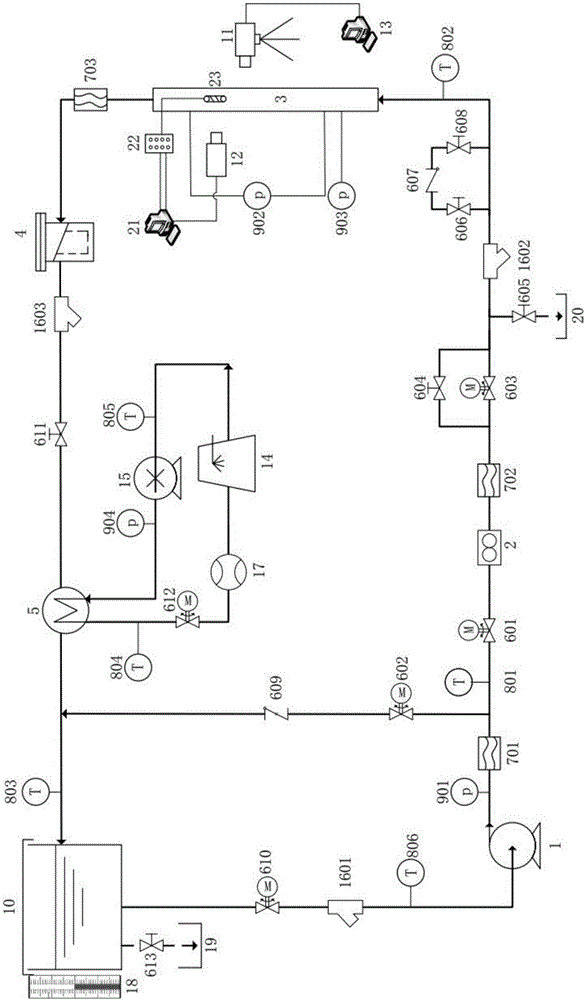

[0042] like figure 1 As shown, the present invention relates to a hydraulic scouring test system for the lower nozzle of a nuclear reactor fuel assembly, comprising a double-suction pump 1 on the main circulation circuit and a first filter 1601 on the upstream pipeline of the double-suction pump 1, and the upstream of the first filter 1601 The tenth valve 610 on the pipeline and its upstream water tank 10, the sixth temperature sensor 806 installed on the pipeline between the double suction pump 1 and the first filter 1601, the liquid level gauge 18 on the side of the water tank 10, they are in the loop The functions are to provide the pressure head and flow required for the entire test circuit, filter the pump inlet fluid, adjust the pump inlet flow, store the fluid and provide the required pressure head for the pump inlet, monitor the pump inlet fluid temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com