Nest floating method

A netting and netting technology, which is applied in the field of marine fishery equipment, can solve the problems that the netting is easy to attach to shellfish and other organisms, the time-consuming fishing of aquaculture, and the hidden dangers of safety. , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

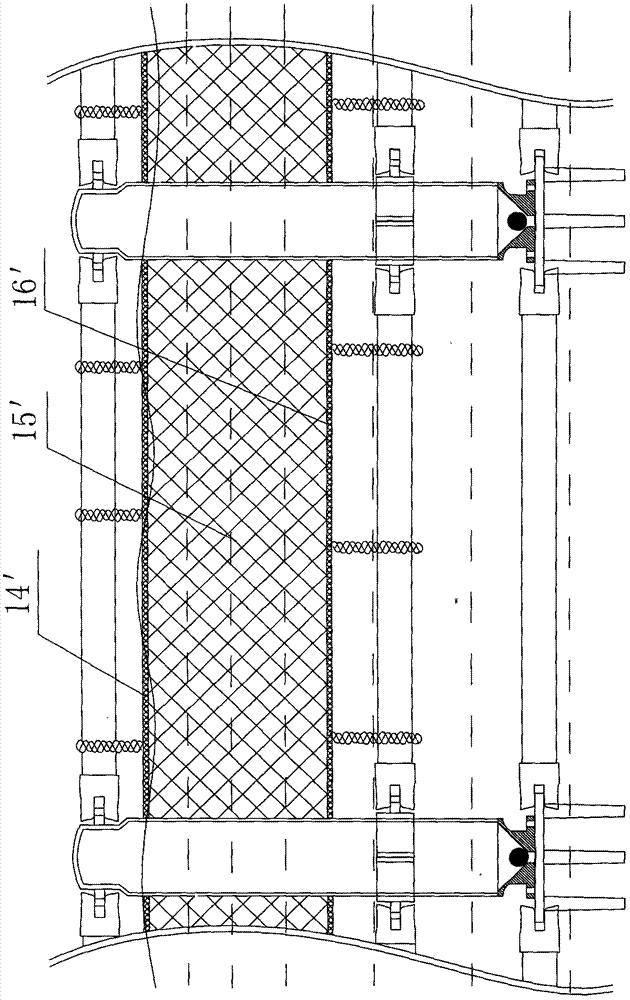

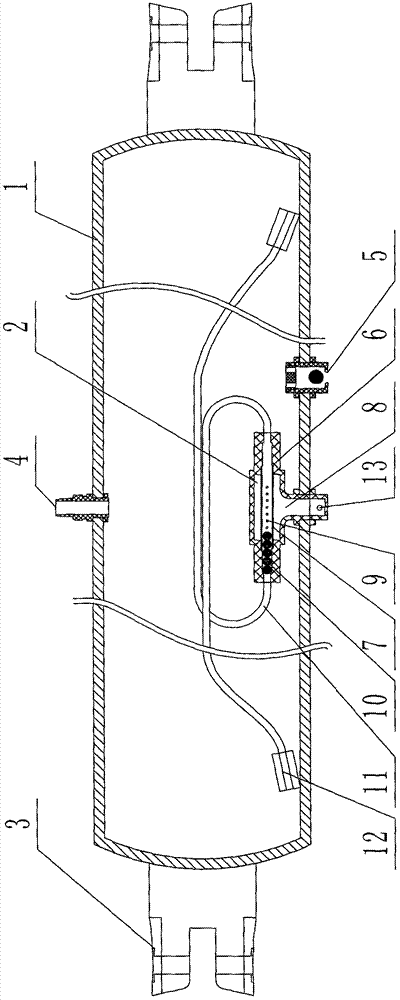

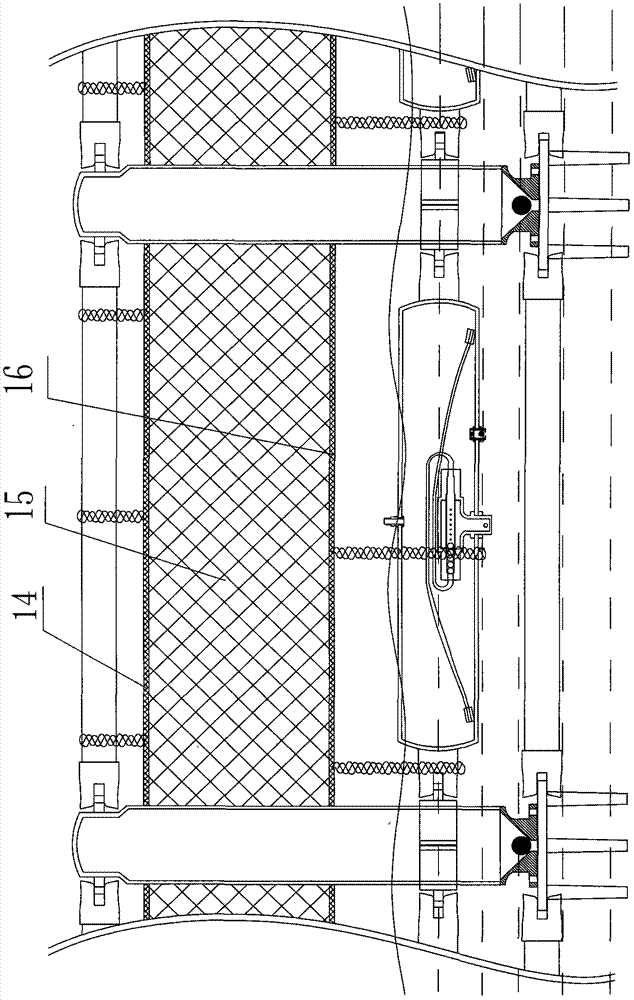

[0020] Such as figure 2 As shown, a horizontal buoyancy pipe of a sinking-floating net cage involved in the present invention comprises a buoyancy pipe 1 and a T-shaped drain valve 2, and two ends of the buoyancy pipe 1 are provided with fork joints 3 for connecting with The vertical buoyancy pipes of the sinking and floating net cages are connected, and the buoyancy pipe 1 is provided with inlet and outlet ports 4 and water inlets 5 up and down, wherein the inlet and outlet ports 4 are arranged on the upper part of the body of the buoyancy pipe 1, and the water inlet is arranged on the buoyancy pipe. 1 the lower part of the pipe body; the T-shaped drain valve 2 is arranged on one side of the water inlet 5 inside the buoyancy tube 1, and the T-shaped drain valve 2 includes a valve body 6 and an inner pipe 7 inside the valve body 6, the described The valve body 6 is provided with a drain chamber 8, and the inner pipe 7 is provided with several inner drain holes 9, the inner dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com