Micro regulating buckwheat sheller

A technology of buckwheat shelling machine and outer barrel, which is applied in the direction of grain shelling, grain processing, application, etc. It can solve the problems of low production efficiency, difficult to adjust the working gap accurately, and high crushing rate, so as to improve efficiency and improve the whole kernel rate , Complete shelling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

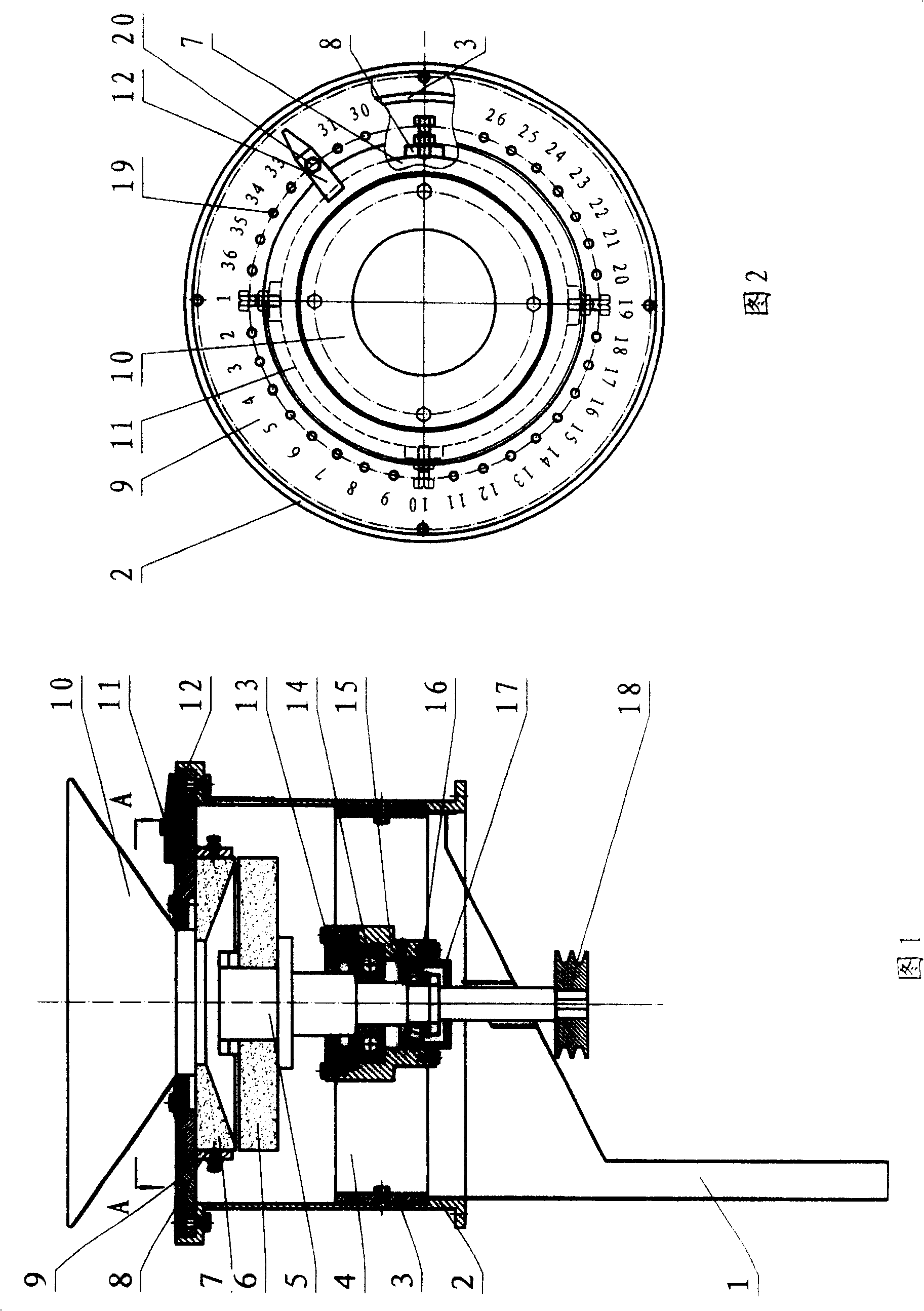

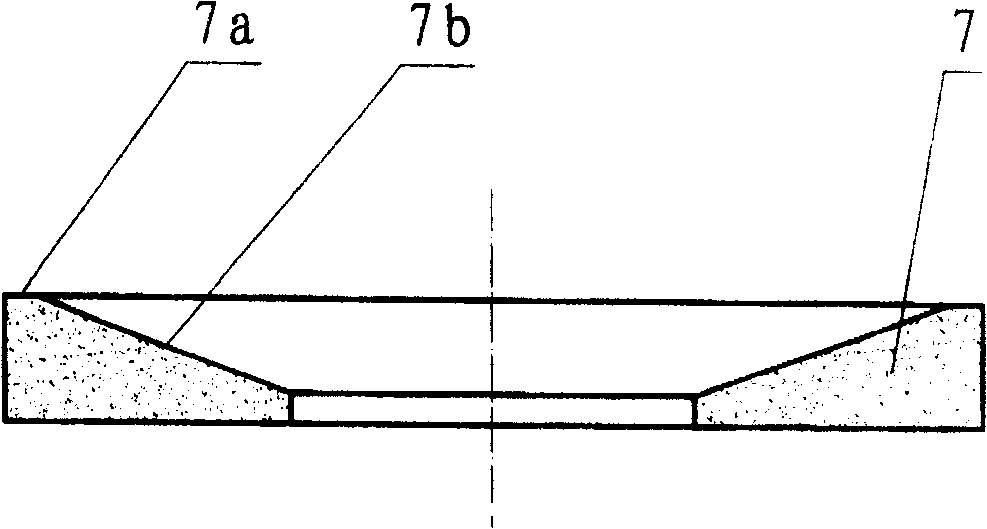

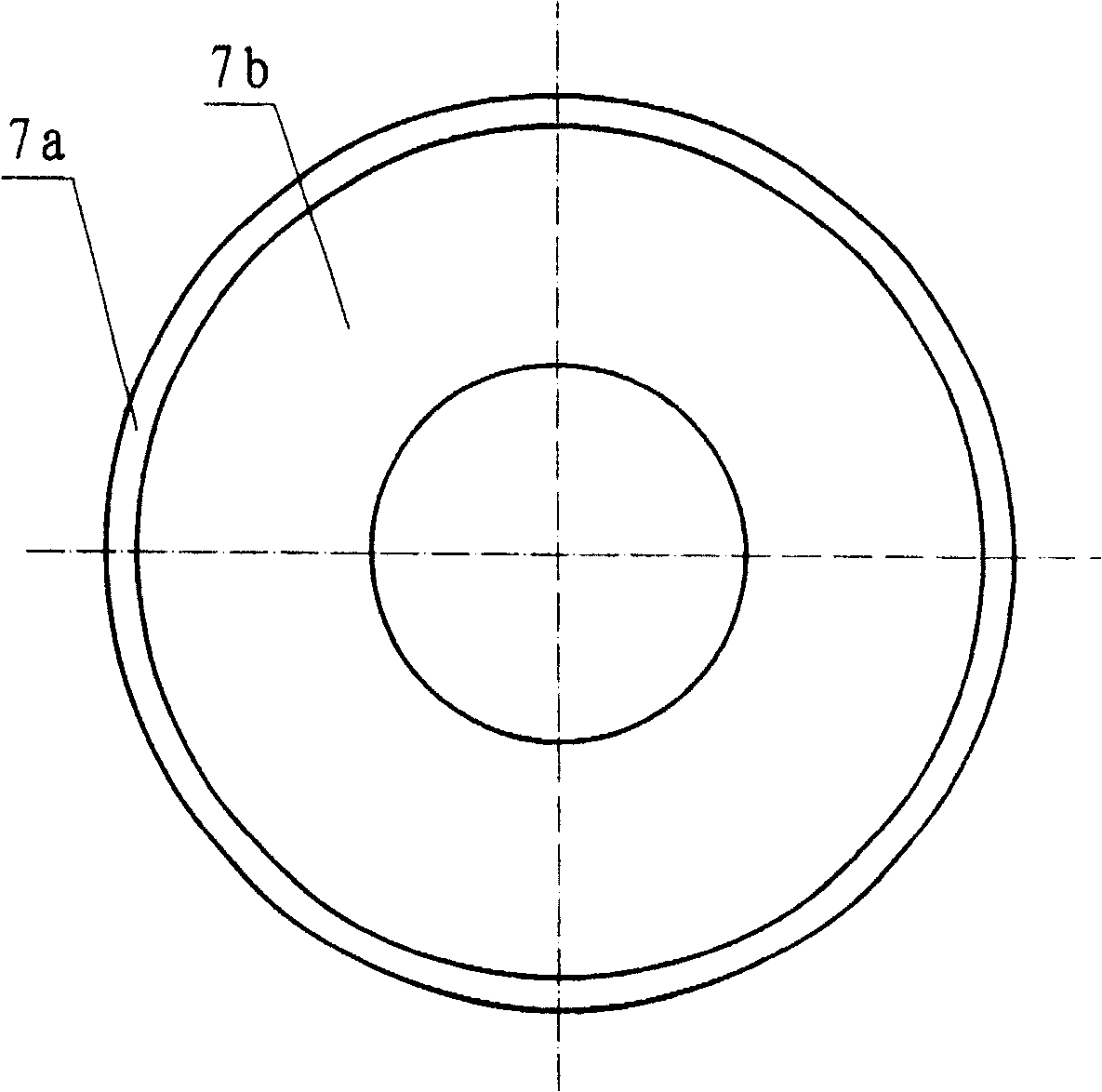

[0015] As shown in the drawings, the present invention has an outer barrel 2 as an outer cover, an inner sleeve 3 is housed in the outer barrel 2, and a bearing seat 15 is arranged at the center of the inner sleeve 3, and a rib is used between the bearing seat 15 and the inner sleeve 3 The plates 4 are connected, and there are several ribs 4, which are evenly distributed around the bearing seat 15, so that the bearing seat 15 and the inner sleeve 3 are integrated; Bearing 14 and bearing 16 are also housed between shaft 5 and bearing seat 15, and bearing 14 and bearing 16 are compressed and fixed with gland 13 and gland 17, guarantee that rotating shaft 5 operates flexibly and reliably; Belt pulley 18 is so as to be connected with power transmission device; Driving wheel 6 is housed on rotating shaft 5, and driving wheel 6 is a circular flake emery wheel; Loam cake is housed on the top of outer barrel 2, and driving wheel is housed in the bottom of loam cake 6 matching fixed wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com