Automatic walnut shell breaking, separating, kernel taking machine and use method thereof

An automatic walnut shelling and walnut technology, which is applied in the field of walnut processing, can solve the problems of controlling the impact distance of walnuts, the impact force cannot be controlled, and the walnuts cannot be broken.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

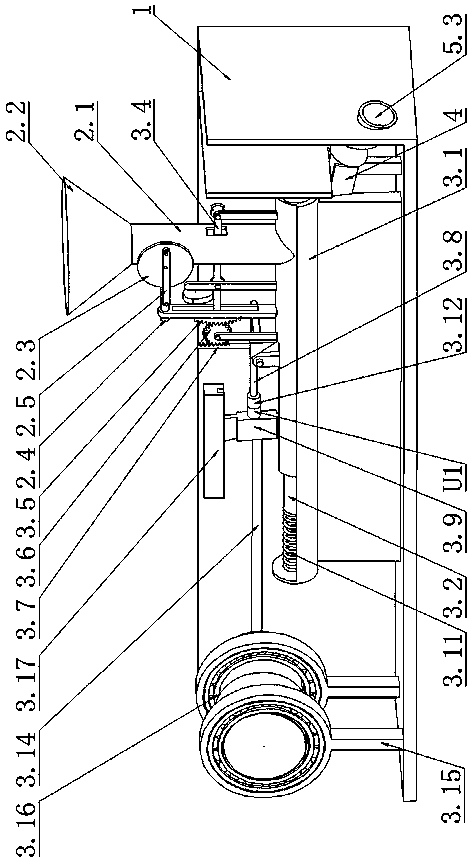

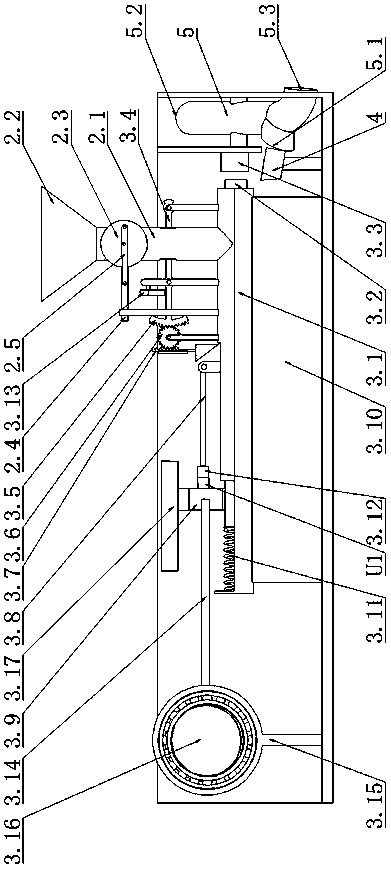

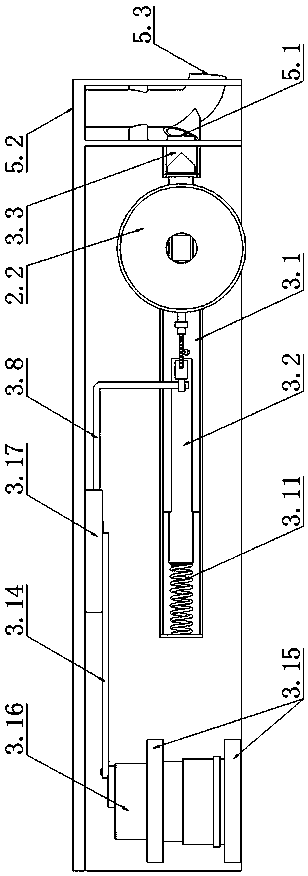

[0036] Such as Figure 1 to Figure 6 As shown, the present embodiment provides a walnut automatic shell breaking, separation, and kernel extraction machine, including a fruit drop control mechanism, a crushing mechanism, and a casing 1; A slotted fruit drop tube 2.1; the number of the first slots is two, and they are arranged oppositely; the crushing mechanism includes a striking rod sleeve 3.1, a striking rod 3.2, a hit block 3.3, a first connecting rod 3.4, and a second connecting rod 3.5. Gear with damping 3.6, rack 3.7 with wedge-shaped block at the bottom, third connecting rod 3.8, slider 3.9, transmission assembly that drives slider 3.9 to reciprocate horizontally, and the first power source that provides power for the transmission assembly and the impact force control circuit; the impact rod sleeve 3.1 is installed in the casing 1 through the sleeve support frame 3.10, and is vertical and connected with the fruit drop tube 2.1, the first end is an open end, and the seco...

Embodiment 2

[0069] This embodiment provides a method for using a walnut automatic shell breaking, separation, and kernel extraction machine, which is implemented based on the walnut automatic shell breaking, separation, and kernel extraction machine described in Example 1, including the following steps:

[0070] S1, input a preset value in the controller according to the impact force required for the type of walnut to be processed, and the first power supply supplies power to the electromagnetic switch U1;

[0071] S2, a single walnut passes through the fruit drop tube 2.1, knocks the baffle plate of the first connecting rod 3.4 and the baffle plate of the second connecting rod 3.5, and then falls into the striking rod sleeve 3.1, and the second connecting rod 3.5 rotates, which is different from the radial direction. The fully meshed gear 3.6 rotates, driving the rack 3.7 meshed with the gear 3.6 to move upwards and adjust the position of the wedge block;

[0072] S3, the first power sou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com