Peanut husking and cleaning all-in-one machine

An all-in-one, shelling technology, applied in the direction of shelling, solid separation, sieving, etc., can solve the problems of complicated procedures, large peanut pods and fine sand not peeled from peanut kernels, and single function, and achieve strong shelling ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]Embodiment 1: This embodiment aims to provide a peanut peeling and cleaning all-in-one machine, which is mainly used for the peeling and cleaning process of peanuts, aiming at the peanut shelling and cleaning output of peanuts existing in the existing structure There are many unpeeled large peanut pods and fine sand impurities, which are inconvenient to use and have a complicated structure. In the actual use process, shelling and cleaning are two continuous processes, which are bound. Based on this, this implementation For example, peanut shelling and cleaning are combined into one machine, which can meet the functions of peanut shelling and cleaning at the same time.

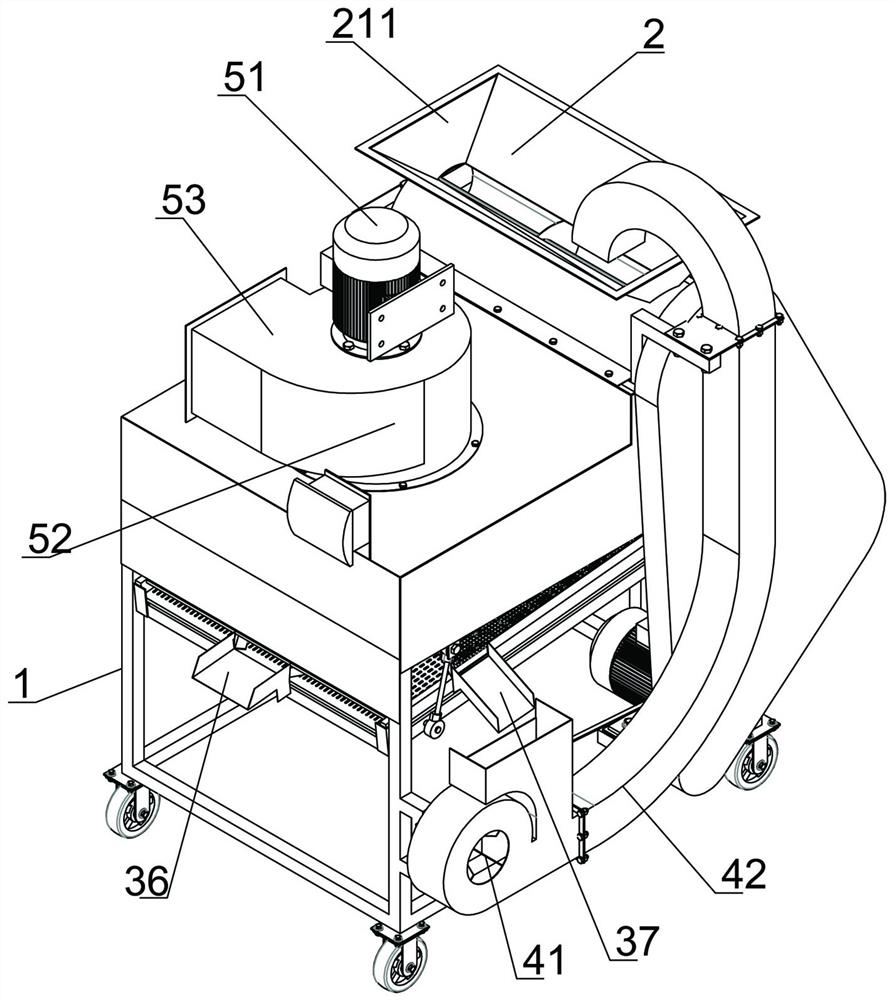

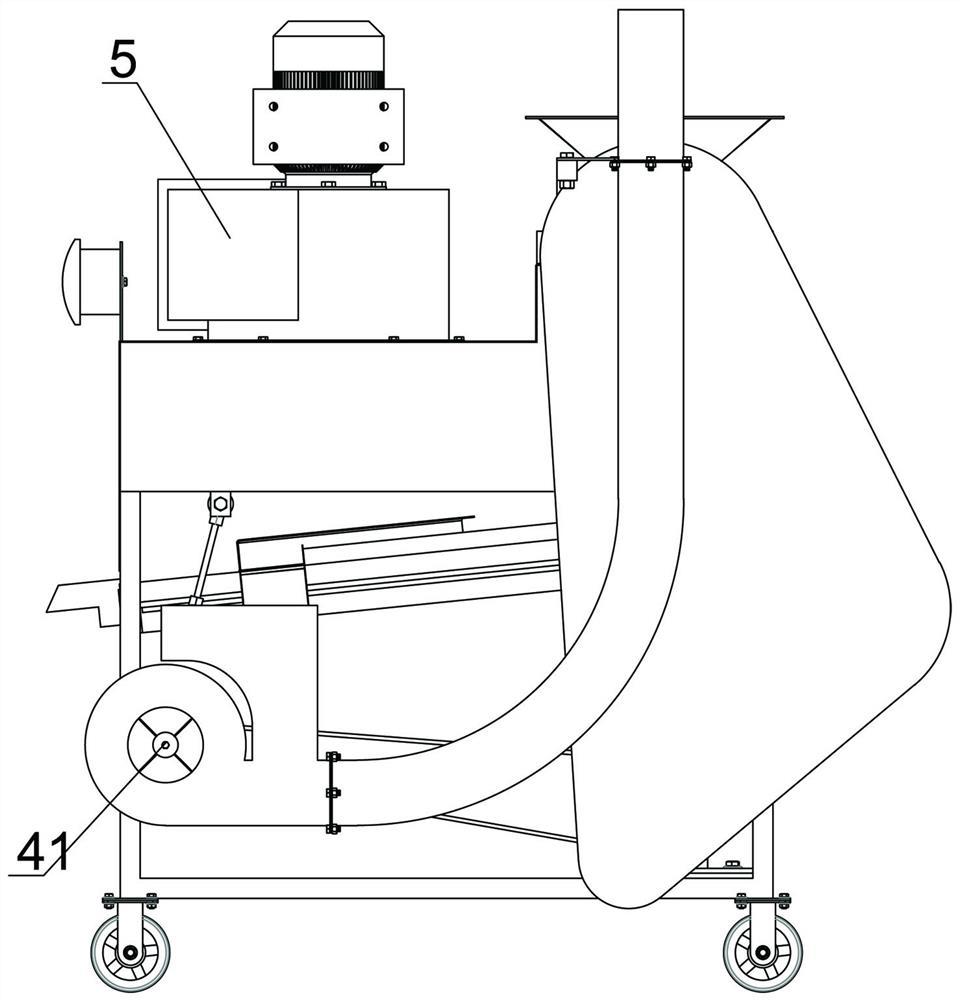

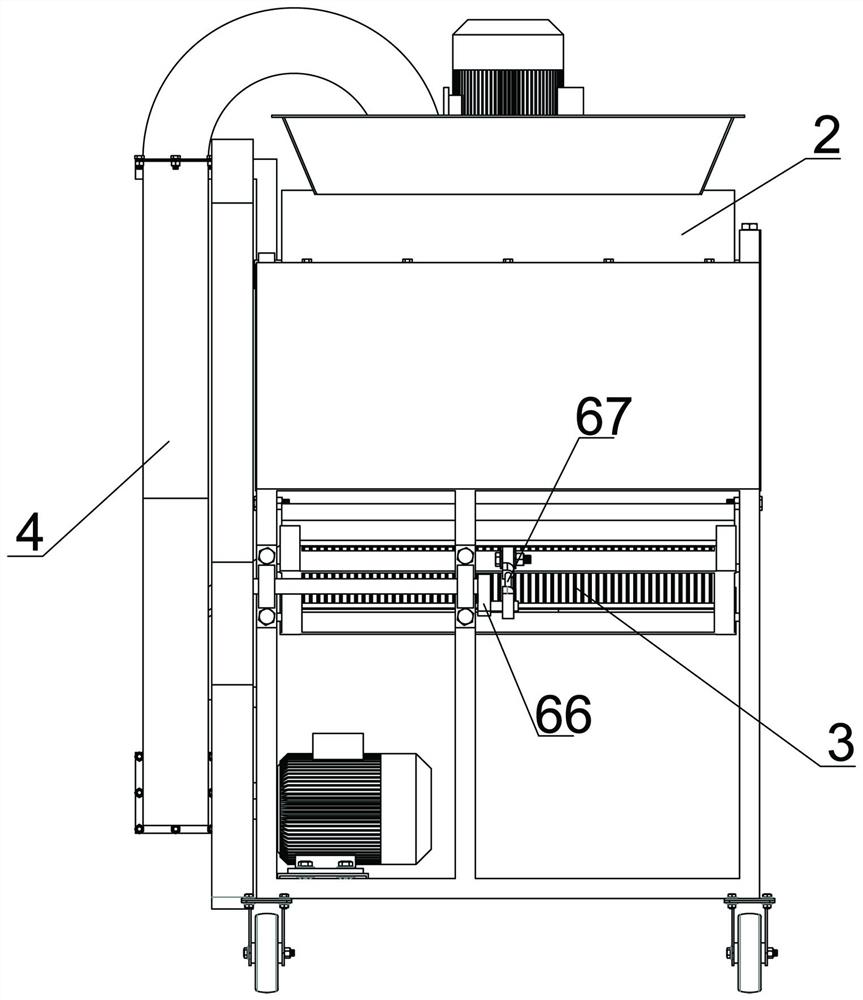

[0036] Such as Figure 1-5 As shown in , a peanut shelling and cleaning all-in-one machine includes a frame 1, a shelling mechanism 2, a shelling power structure, a cleaning mechanism 3, a vibration driving structure and a feedback mechanism 4; the bottom of the frame 1 can be One-way wheels, universal w...

Embodiment 2

[0047] Embodiment 2: This embodiment is basically the same as Embodiment 1, and its difference is: this embodiment is for example 5 and Figure 9 Shown in the transmission part of the present invention is described.

[0048] In this embodiment, the outer side of the transmission part is provided with a shell, which is used to protect the belt and the pulley. The shelling power structure includes a shelling pulley 64 arranged at the driving end of the main rolling shaft, and a driving motor is arranged at the bottom of the frame 1 61, the rotating shaft of driving motor 61 is provided with composite double pulley 62, the feedback driving wheel 63 of feedback blower blower and the peeling pulley 64 are respectively through belt and composite double pulley 62 transmission connections, and described vibration driving structure comprises belt and The vibrating drive wheel, rotating shaft, eccentric block, eccentric bar and swing bar that peel off the pulley transmission connection,...

Embodiment 3

[0051] Embodiment 3: This embodiment is basically the same as Embodiment 1, the difference is that this embodiment further explains the structure of the combined shell.

[0052] In this embodiment, the combined housing includes a loam cake 210, a left baffle plate 25, a right baffle plate 26, a front baffle plate and a rear baffle plate; On the frame 1, the left baffle plate 25 and the right baffle plate 26 are fixed on the frame, and respectively docked with the left and right sides of the upper cover 210 to form a closed structure; the concave plate screen includes columns, inner plates, and middle plates And the outer plate 28, the columns run through the fixed set of the inner plate, the middle plate and the outer plate, and the right baffle, the partition groove and the left baffle are provided with fixed grooves matching the inner plate, the middle plate and the outer plate, The outer plate 28 is provided with a fixed plate 29, and the fixed plate 29 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com