Isoceles multi-axis reinforced gridding cloth and preparation process thereof

A preparation process and mesh cloth technology, applied in building maintenance, textile, liquid/gas/steam removal, etc., can solve the general applicability, anti-deformation effect and bearing capacity of building walls and building components, and stability General and other problems, to achieve the effect of improving the overall anti-deformation effect and carrying capacity, improving the overall anti-deformation effect and carrying capacity, and good hollowing out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

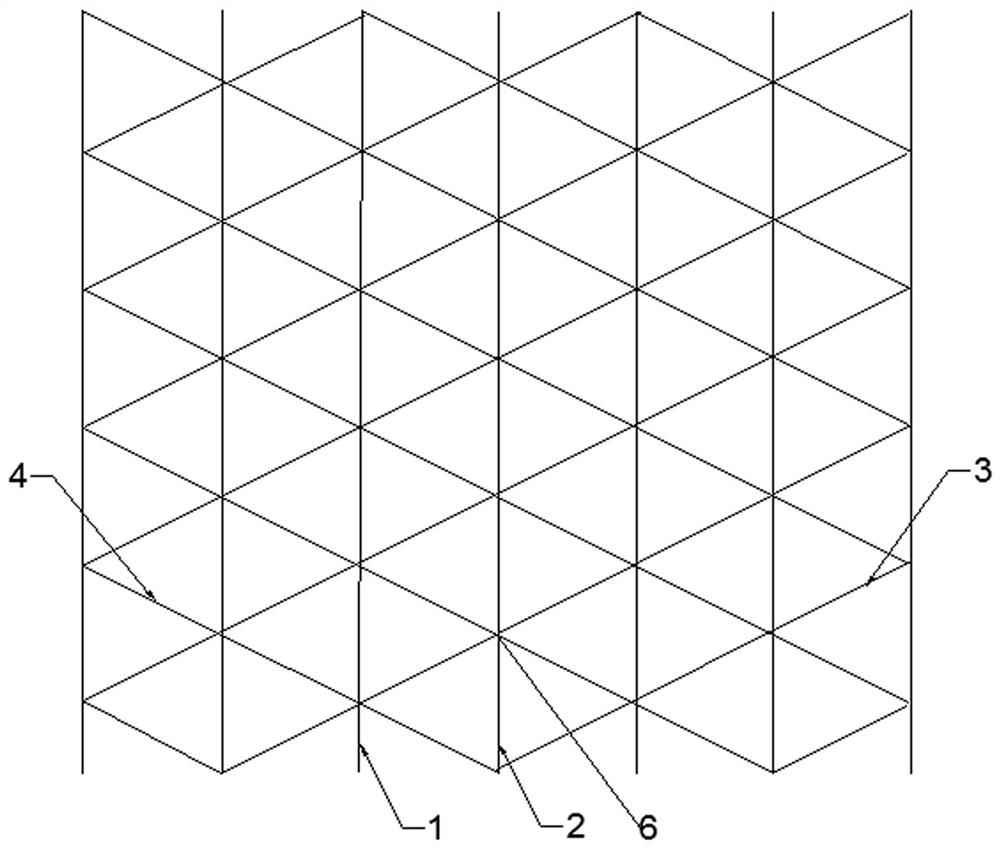

[0072] see figure 1 As shown, it shows an isosceles multiaxial reinforcement mesh cloth, with a plurality of weft thread groups consisting of a first weft thread 3 and a second weft thread 4, and a plurality of weft threads consisting of a first warp thread 1 and a second warp thread 2 The warp group composition;

[0073] Specifically, the first weft 3 and the second weft 4 are arranged to cross each other, the first warp 1 and the second warp 2 are arranged longitudinally parallel to each other, and the intersection of the first weft 3 and the second weft 4 is the same as the first warp 1 , and the intersection of the first latitude 3 and the second latitude 4 and the first meridian 2 all form a node 6, and the connection of any three adjacent nodes 6 in a triangular distribution forms an isosceles triangle (including equilateral triangle);

[0074] The preparation process of the above-mentioned mesh cloth is as follows: firstly, by one or more of vinyl fiber untwisted fila...

Embodiment 2

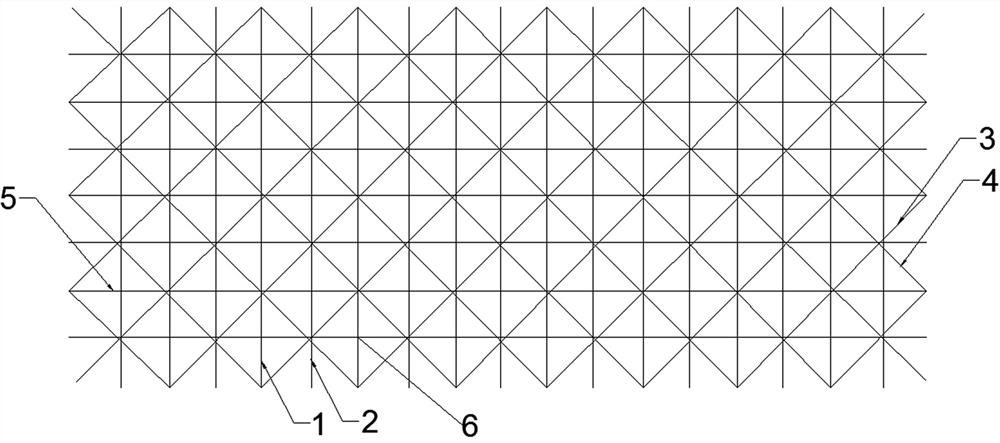

[0076] see figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the third weft 5 is added, and the connection of any three adjacent nodes 6 in a triangular distribution forms an isosceles right triangle. Specifically, in terms of the preparation process, That is, the third wefts 5 of each weft group are laid horizontally on the first warp 1 at equal distances, and then the first wefts 3 of each weft group are laid in parallel at equal distances and cross-layed on the third weft 5 respectively. The second weft threads 4 of each weft thread group are laid in parallel at equal distances and are respectively laid on the first weft threads 3 crosswise, and finally the second warp threads 2 of each warp thread group are longitudinally laid and laid on two adjacent first warp threads in turn. 1; at the same time, during the whole process, the first weft 3 is inclined to the upper right by 45 degrees relative to the horizontal line, and the second weft 4...

Embodiment 3

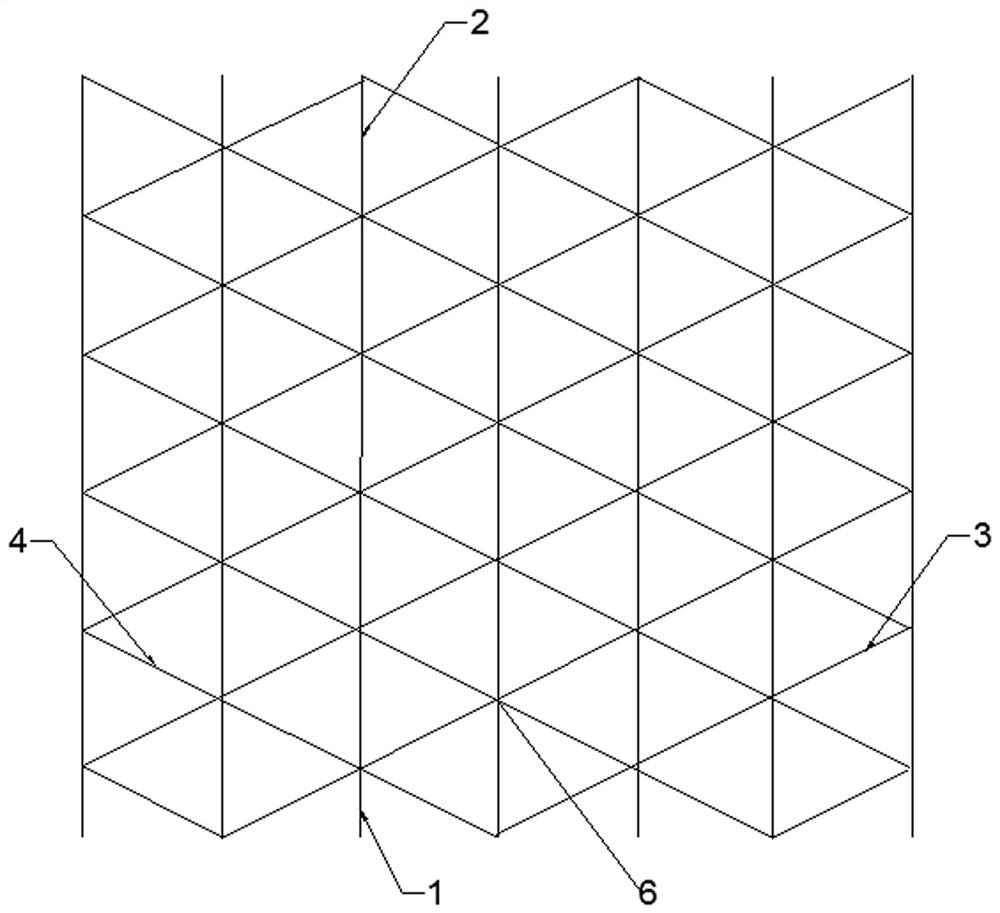

[0078] see image 3 As shown in the figure, the difference between this embodiment and Embodiment 1 is that the first warp 1 and the second warp 2 of each warp group are in a one-to-one correspondence with longitudinal double-strand winding (double-strand winding is the prior art in the field, so here It will not be explained much and not shown in detail in the drawings), so that the intersection of the first weft 3 and the second weft 3 is fixed in the middle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com