Tartary buckwheat case-hardening and hulling method

A technology for tartary buckwheat and tartary buckwheat kernels is applied in grain hulling, grain processing, application and other directions, which can solve the problems of long soaking time, high energy consumption, serious nutritional loss, etc., to reduce energy consumption and water consumption, and improve production efficiency. , the effect of small nutrient loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

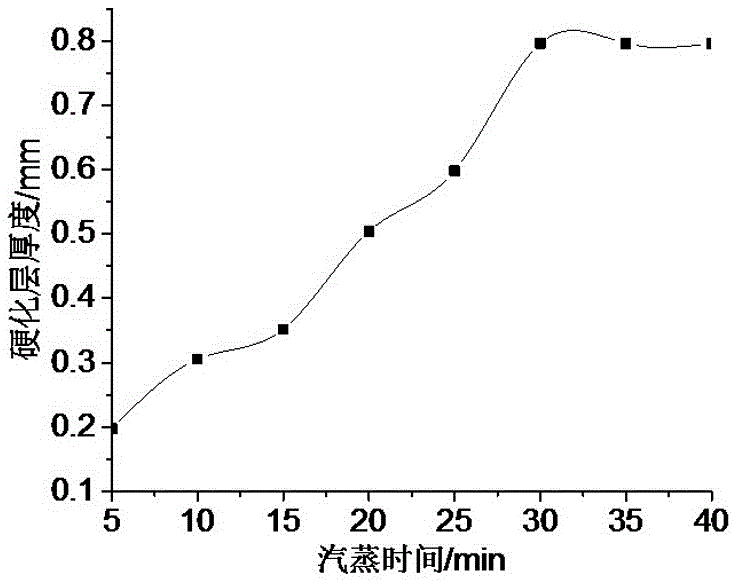

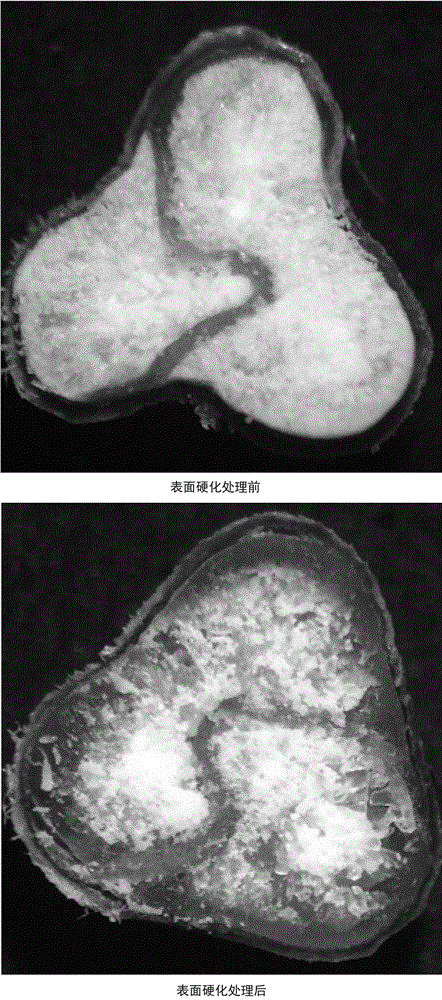

[0039] Embodiment 1: A kind of tartary buckwheat surface layer hardening shelling method

[0040] The tartary buckwheat variety used in the husking test was Diku No. 1, which was produced in Diqing Prefecture, Yunnan Province.

[0041] The shelling test includes the following steps:

[0042] (1) Cleaning and grading: remove impurities, dust and classify tartary buckwheat raw materials;

[0043] (2) Soaking in clean water: Soak tartary buckwheat in clean water for 40 minutes at 25°C, so that the surface infiltration depth of tartary buckwheat kernels reaches an average of 0.5mm, and the infiltration depth is as uniform as possible. In the present embodiment, the amount of water added for soaking is 0.9 times of the volume of tartary buckwheat. Drain after soaking.

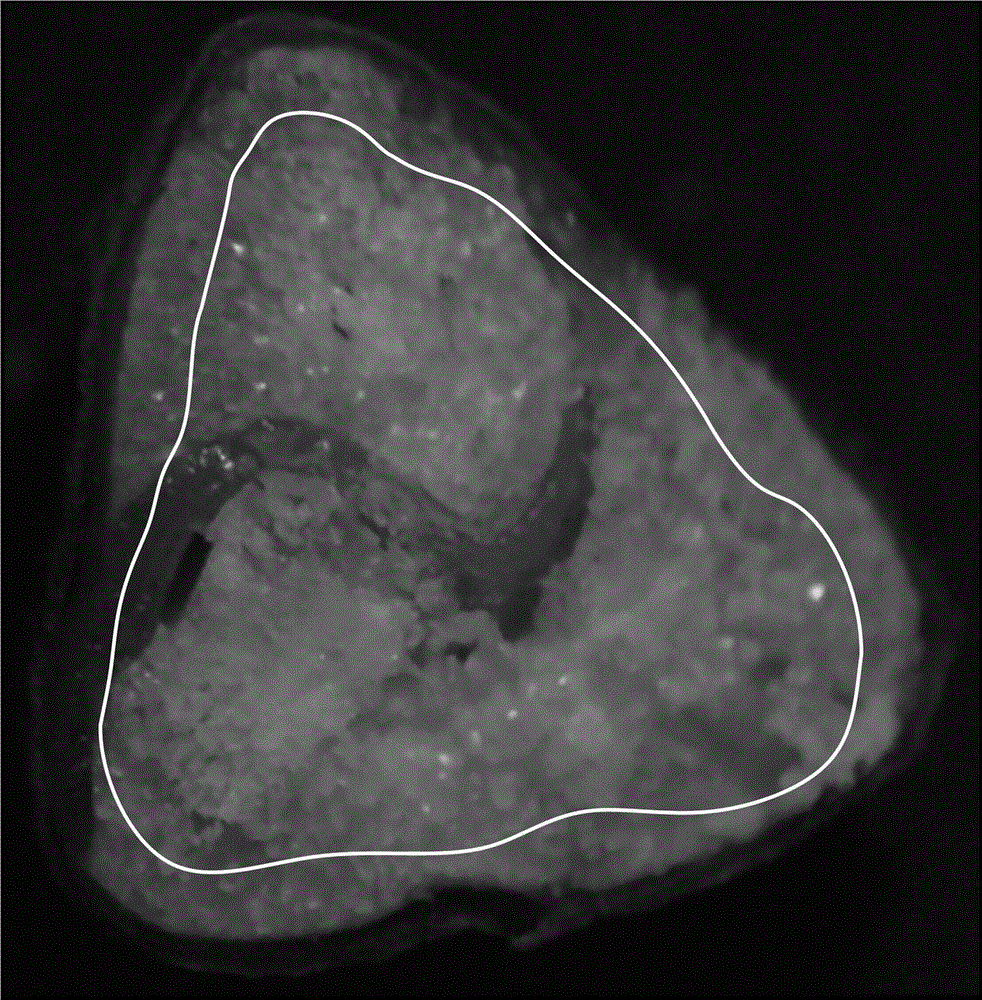

[0044] The method for measuring the surface infiltration depth of tartary buckwheat kernels is: measure the distance from the infiltration water line to the edge of tartary buckwheat kernels under a microscope, a...

Embodiment 2

[0053] Embodiment 2: A kind of surface hardening shelling method of tartary buckwheat

[0054] The tartary buckwheat variety used in the husking test was Diku No. 1, which was produced in Diqing Prefecture, Yunnan Province.

[0055] The invention provides a method for surface hardening and shelling of tartary buckwheat, comprising the following steps:

[0056] (1) Cleaning and grading: remove impurities, dust and classify tartary buckwheat raw materials;

[0057] (2) Soaking in clean water: Soak tartary buckwheat in clean water for 40 minutes at 25°C, so that the surface infiltration depth of tartary buckwheat kernels reaches an average of 0.5mm, and the infiltration depth is as uniform as possible. In the present embodiment, the amount of water added for soaking is 0.9 times of the volume of tartary buckwheat. Drain after soaking.

[0058] The method for measuring the surface infiltration depth of tartary buckwheat kernels is: measure the distance from the infiltration wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com