Flexible walnut shell breaking machine

A technology of shelling machine and walnut, which is applied in the fields of shelling, pod removal, food science, etc. It can solve the problems of difficult separation of shells and skins and high rate of broken kernels, so as to improve the rate of whole kernels, improve the quality, and facilitate sorting and removal of impurities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

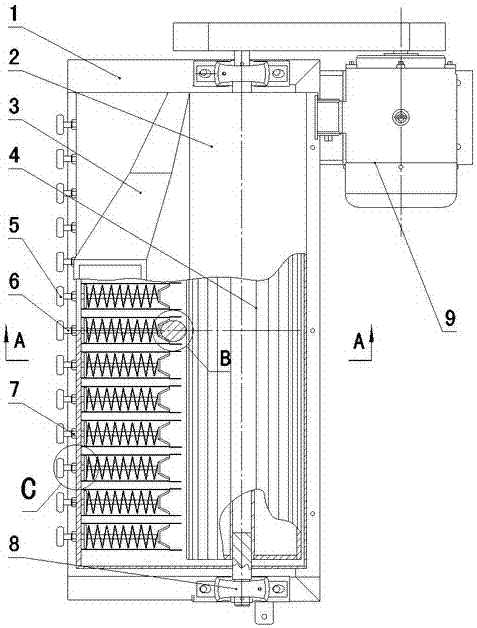

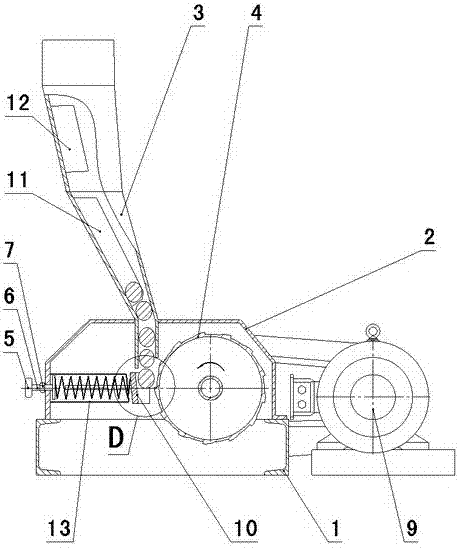

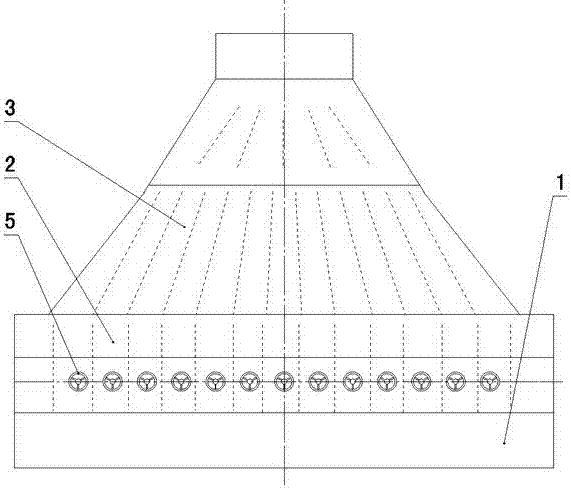

[0018] As shown in the accompanying drawings, the present invention has a machine base 1, and organic cover 2 is installed on machine base 1, and broken shell roller 4 is installed in machine cover 2, and broken shell roll 4 is installed on the machine base 1 by bearing block 8 , on the surface of the shell breaking roller 4, there are several shell breaking pressure heads 4a in the axial direction. The shell breaking pressure heads 4a are teeth protruding outwards, and the surface of the teeth is arc-shaped, so as to gradually exert pressure on walnuts. pressure; the shell breaking roller 4 is connected with the motor 9 through a belt drive, and there is a feed hopper 3 on the machine cover 2, and there are several distribution plates 11, 12 in the feed hopper 3, and the distribution plates 11, 12 are placed in the feed hopper 3, several feed passages are formed, below each feed passage there is a shell-breaking pallet 10 matched with the shell-breaking roller 4, and a pull ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com