Nut shelling tool

A technology for knives and nuts, applied in the field of nut shelling and peeling knives, can solve the problems of difficulty in controlling the strength, high nut breakage rate, low kernel whole rate, etc., and achieves simple structure, high shelling efficiency, and uniform force application. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

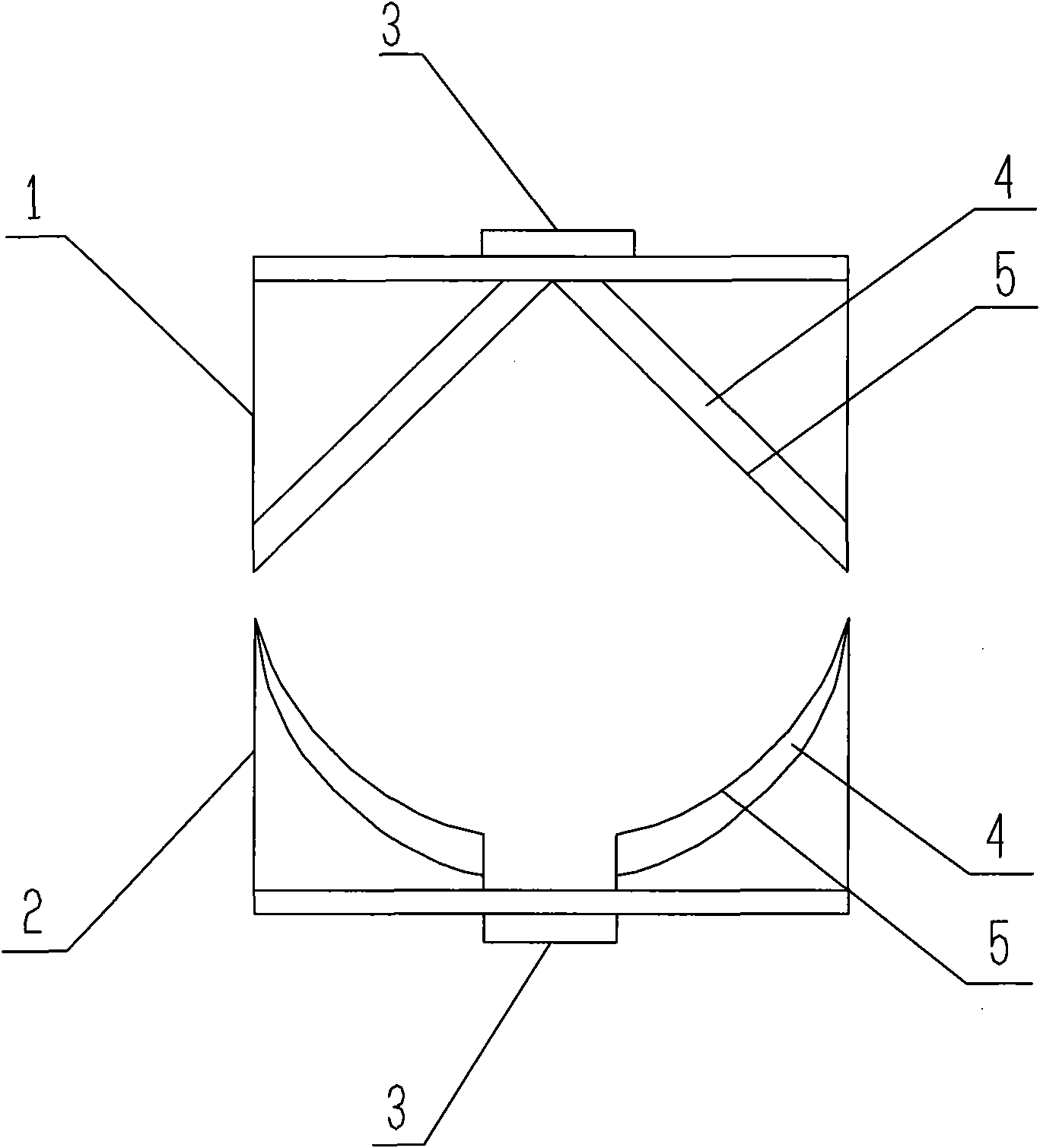

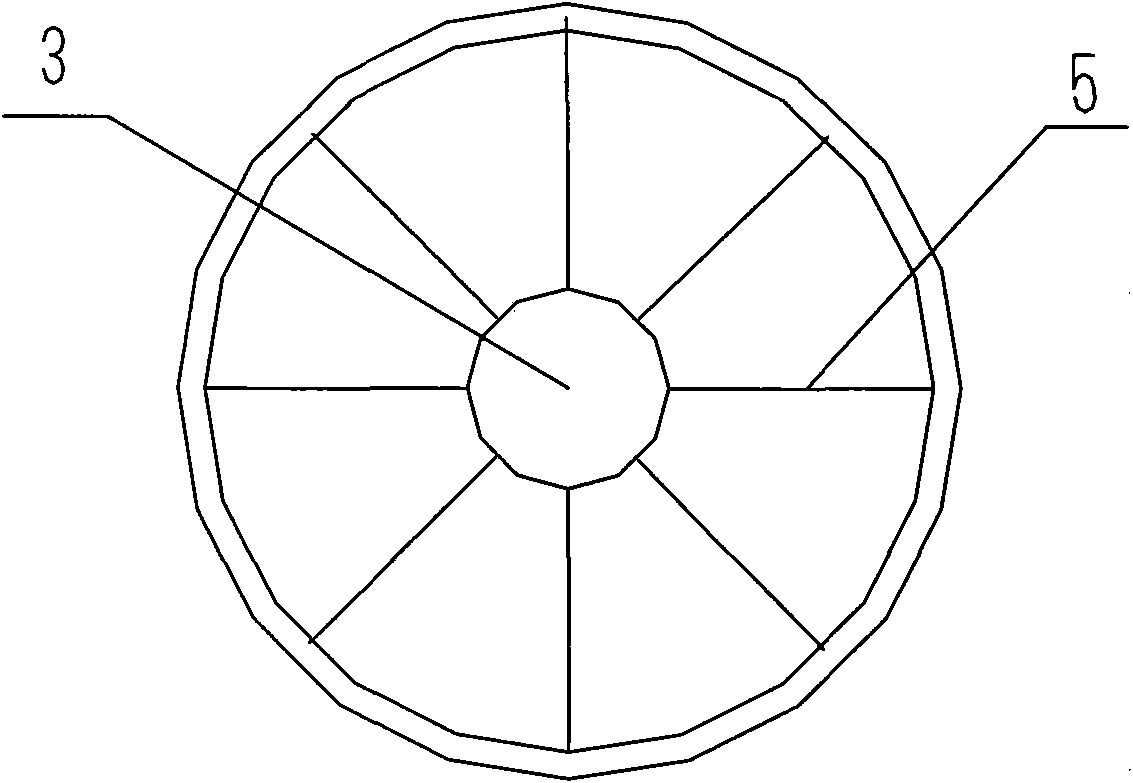

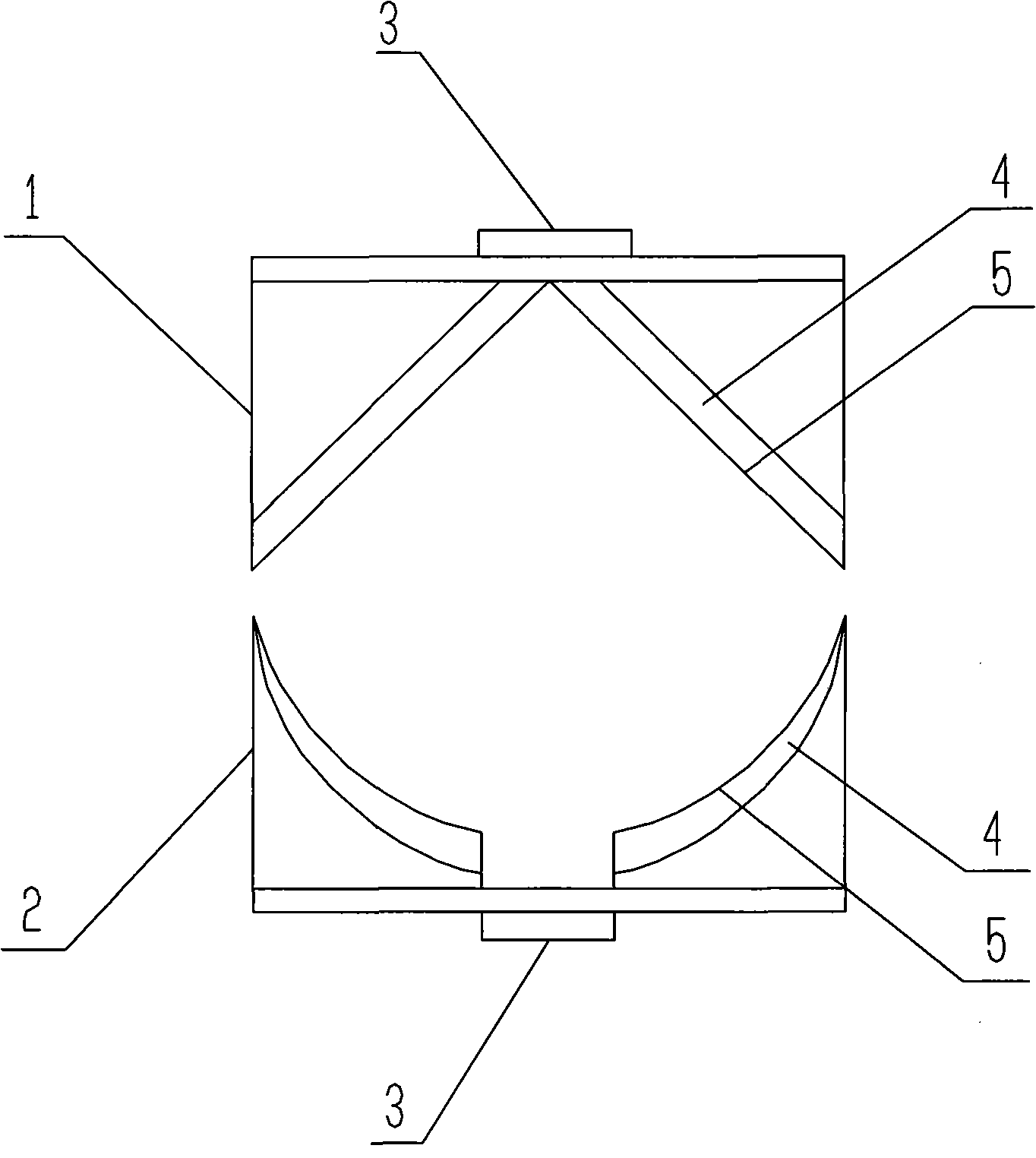

[0013] Such as Figure 1~2 As shown, an embodiment of the schematic diagram of the cross-sectional structure of the nut shelling and peeling tool of the present invention is provided, which includes an upper knife seat 1 and a lower knife seat 2 that rely on positioning pins 3 to cooperate, and the upper knife seat 1 and the lower knife seat The inside of knife seat 2 is evenly equipped with eight blades 4 respectively, and its blade 5 of blade 4 inside described upper knife seat 1 is straight, and its blade 5 of blade 4 inside described lower knife seat 2 is arc-shaped. When working, put spherical or ellipsoidal nuts into the lower knife holder 2 first, since the blade 5 of the inner blade 4 of the lower knife holder 2 is arc-shaped, it can fit closely with the nut shell loaded into the lower knife holder 2 There is no gap, which ensures that a greater pressure can be generated after being stressed; then the upper knife seat 1 and the lower knife seat 2 are placed outside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com