Camellia oleifera fruit shell breaking, extruding and separating device

A technology of squeezing and separating camellia oleifera, which is applied in the field of agricultural machinery, can solve the problems of ignoring the husking efficiency and seed damage rate, high husking efficiency, and low seed damage rate, and achieve high-efficiency husking and separation, effective mechanical Shelling, the effect of improving the rate of shelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

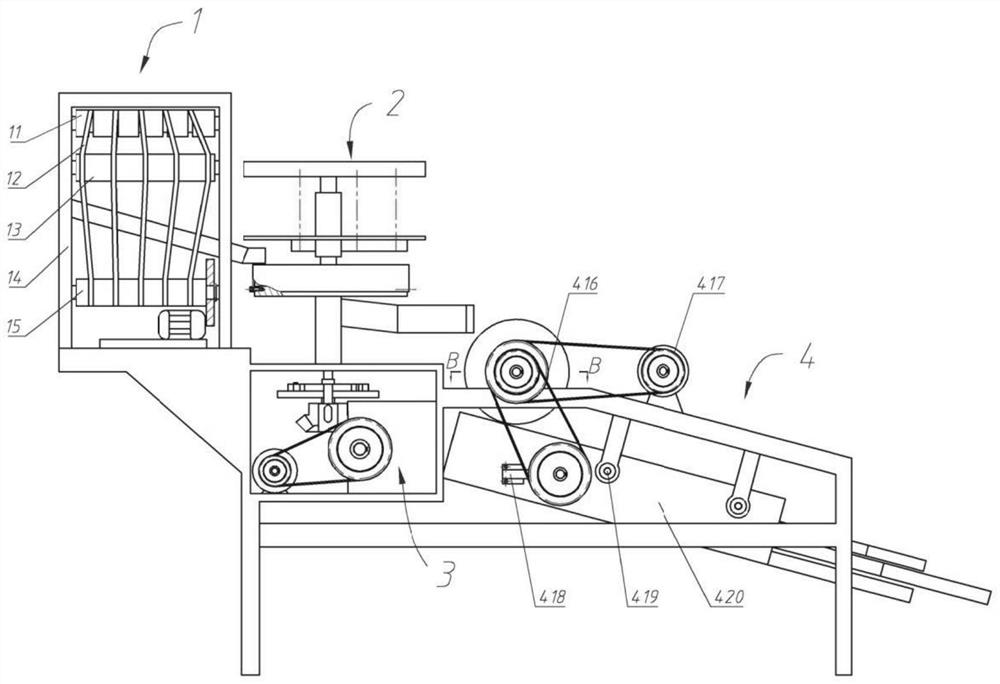

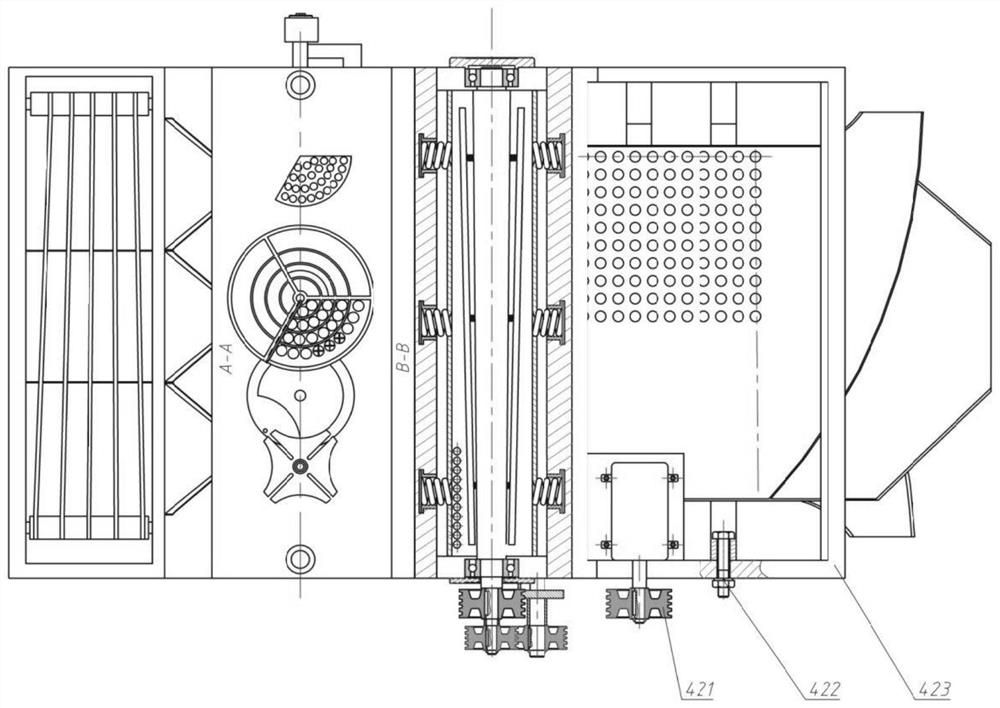

[0027] Such as figure 1 , 2 As shown, the camellia oleifera shell breaking extrusion separation device of the present invention comprises a frame 423, a grading system 1 installed on the upper left side of the frame 423, a shell breaking system 2 and its transmission system 3 installed on the middle part of the frame 423, installed on the Shelling separation system 4 of frame 423 bottom right.

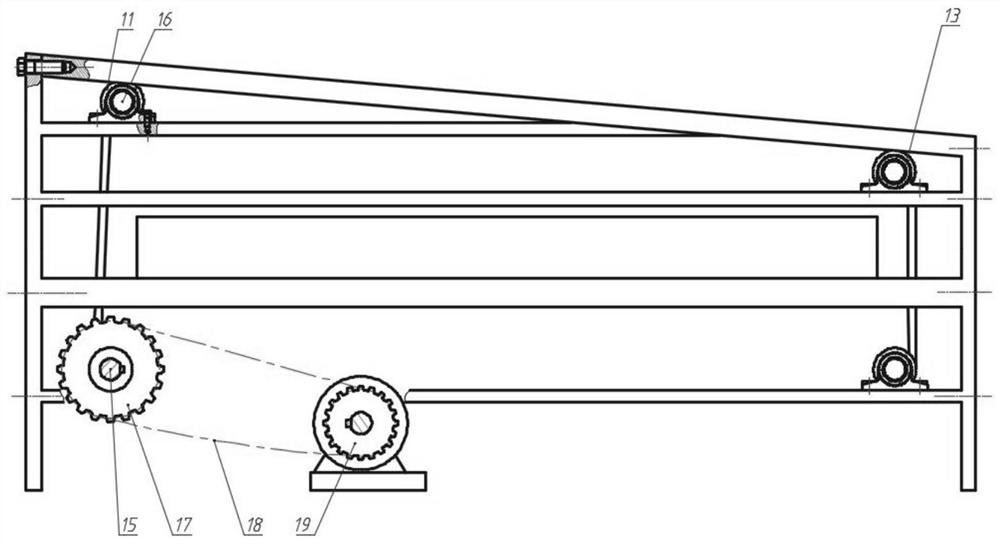

[0028] Such as image 3 As shown, the grading system 1 includes a first grading roller 11, a grading tape 12, a second grading roller 13, a grading frame 14 welded on the frame 423, a grading drive shaft 15, a bearing housing 16, a driven sprocket 17, a chain 18, driving sprocket 19. Wherein, the first classifying roller 11, the second classifying roller 13 and the classifying drive shaft 15 are installed on the classifying frame 14 through the bearing seat 16, and the bearing seat 16 carries out axial fixing to the first classifying roller 11 and the second classifying roller 12 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com