Walnut shell breaking device and application method thereof

A shell breaking device, walnut technology, applied in application, shelling, pod removal, etc., can solve the problems of walnut poor adaptability, low shelling rate, low kernel whole rate, etc., achieve low wear, improve shelling rate, Apply promising effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

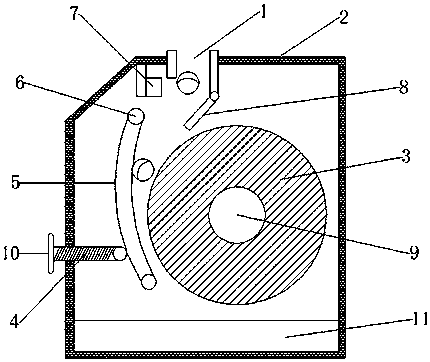

[0020] A device for cracking walnut shells, comprising a walnut feed port 1, a device housing 2, a power grinding wheel 3 and a collection bin 11, characterized in that: a rotatable supporting piece 8 is installed under the walnut feed port 1, and 1 The left side of the bottom is equipped with a liquid nitrogen dryer 7, the center of the power grinding wheel 3 is an engine 9, the left side of the power grinding wheel 3 is a flexible shear extrusion belt 5, and the transmission engine 6 is installed at both ends of the flexible shear extrusion belt 5 On the left side of the flexible shearing extrusion band 5, a strong spring 4 is installed, and the afterbody of the strong spring 4 is equipped with an elastic force regulator 10, thereby forming a walnut shell breaking device. An application method of a walnut shell breaking device is as follows: first start the engine 9 and the transmission engine 6 at the same time, respectively drive the power grinding wheel 3 and the flexible ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com