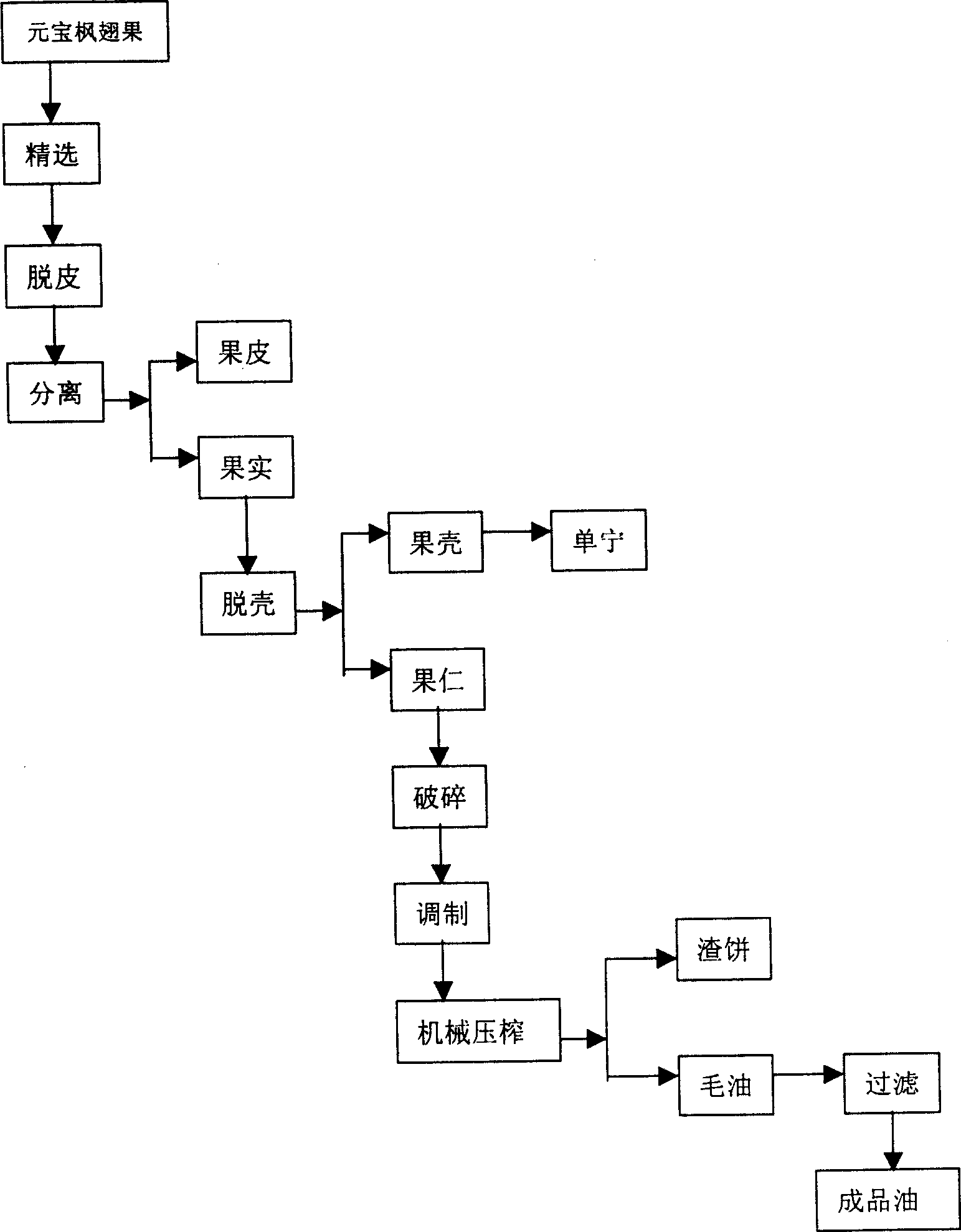

Five-split maple oil preparation process

A preparation process, ingot maple technology, applied in the direction of oil/fat production, production of fat, etc., can solve the problems of reducing oil quality, destroying the content of beneficial substances, protein denaturation, etc., to improve oil quality, reduce production costs, and remove shells. rate increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] like figure 1 As shown, the selected maple samara ingots are firstly selected by winnowing machine and magnetic separator. The winnowing machine mainly screens the branches, leaves and miscellaneous soil in the maple samara, and the magnetic separator mainly screens out the ingots. The iron substances in the maple samara prevent these harmful substances from damaging the quality of the oil and the machine. The water content of the selected Yuanbao maple samara reaches 5%-6%, and the impurity is ≤1%. Then use the sunflower seed peeling machine , improve the sunflower seed peeling machine according to the shape characteristics of Yuanbao maple fruit, adjust the gap between the rollers to achieve the function of removing the outer skin of Yuanbao maple fruit, and make the peeling rate reach 96%; the peeled Yuanbao maple leaf The fruit in the Samara is separated from the peel by a screening machine to ensure that the separation rate reaches 98%. The peanut shelling machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com