Vertical tartary buckwheat huller

A tartary buckwheat and hulling machine technology, which is applied to grain hulling, grain degermination, grain processing and other directions, can solve the problems of high damage rate and many broken tartary buckwheat kernels, and achieve high productivity and improve hulling rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The invention will be further described below in conjunction with the specific embodiments provided by the accompanying drawings and the inventor:

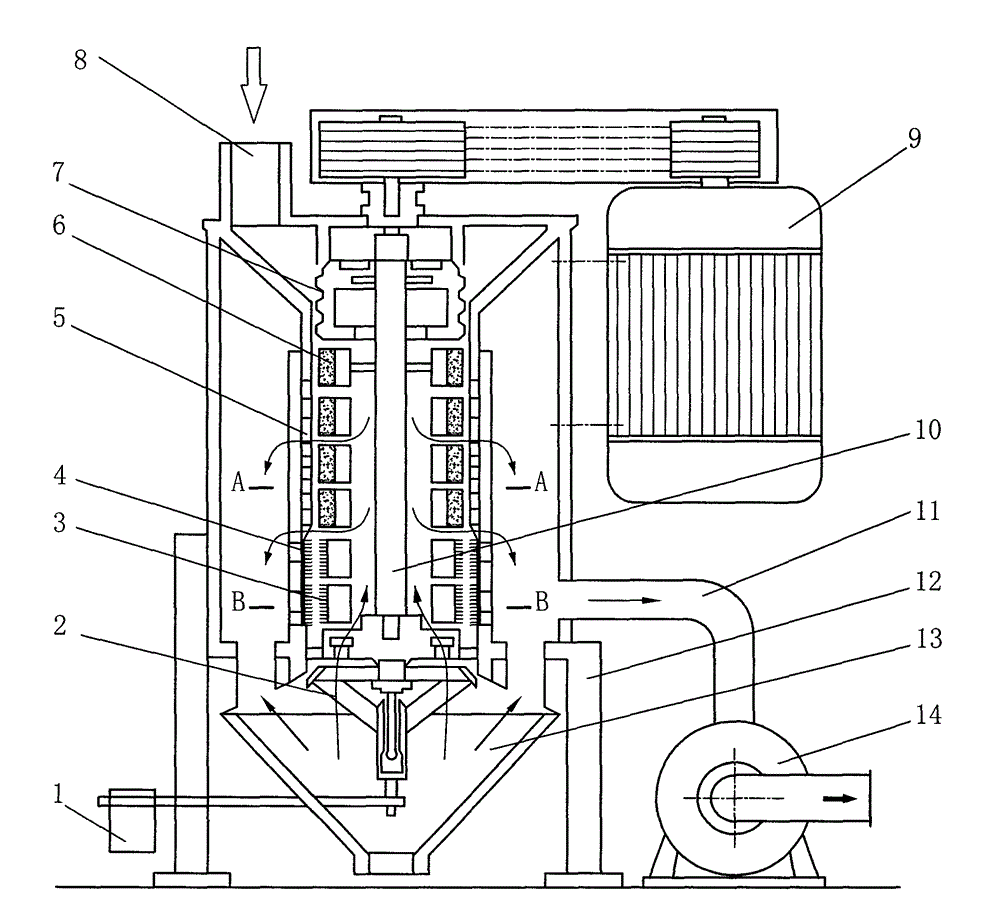

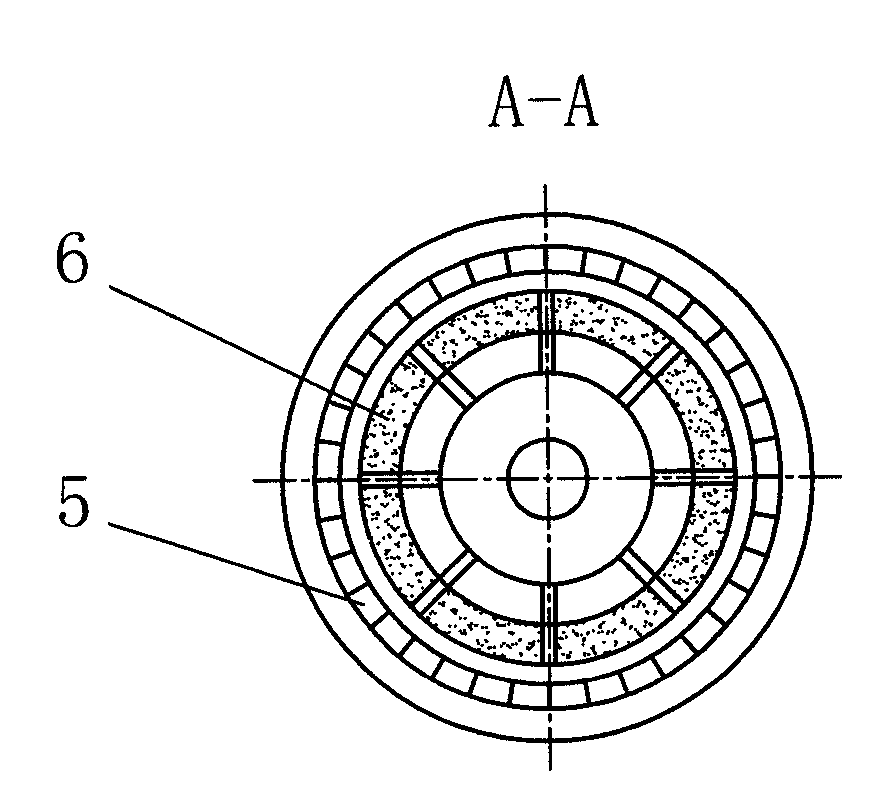

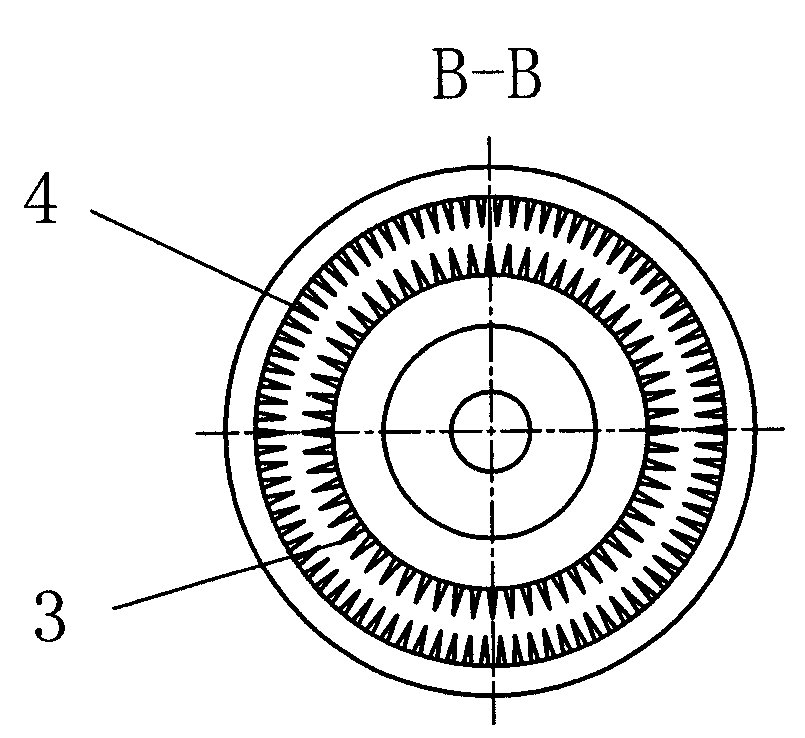

[0014] figure 1 Provided is a main sectional view of a vertical tartary buckwheat hulling machine of the present invention, including a frame 12, the upper left corner of the frame 12 is provided with a feed port 8, and the middle of the frame 12 is provided with a rice sieve 5 , the upper end of the rice sieve 5 is connected to the upper end of the frame 12; the upper end of the rice sieve 5 is trumpet-shaped, and the inner side of the lower end is provided with a screen hole; the side wall of the lower end of the rice sieve 5 is provided with a screen hole part The outer side is connected with the circular baffle plate with the fixed brush 4 at the bottom; the main shaft 10 passes through the center of the rice sieve 5 and the circular baffle plate vertically, one end passes through the bearing installed on the frame 12, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com